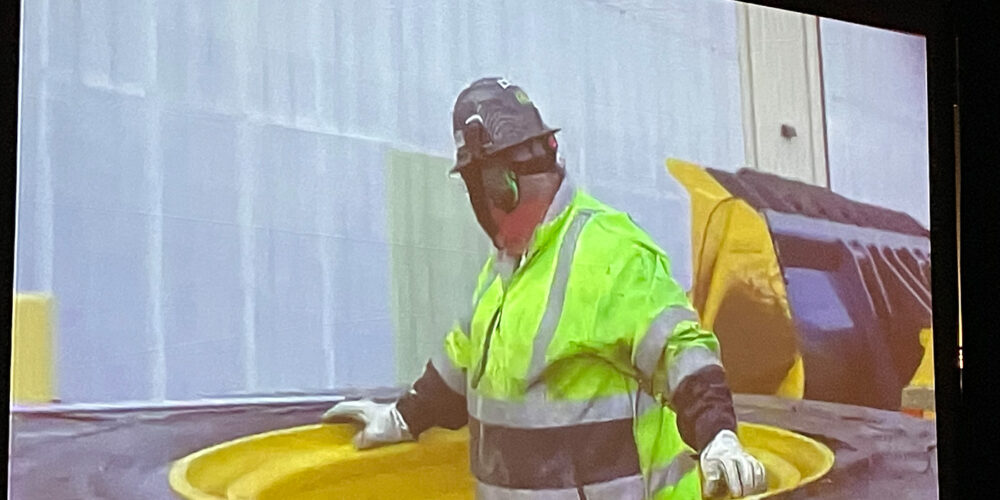

It doesn’t matter how experienced you are in the OTR industry, you should regularly be updated on training to keep you safe during service. At this year’s 68th OTR Conference, Kevin Rohlwing, chief technical officer for the Tire Industry Association (TIA), hosted a live training demo with a digital twist. Instead of showing TIA’s RIST (remove, inspect, snug, torque) safety procedures through a PowerPoint slide or a series of old videos, a live training session was done at the Komatsu Proving Ground just south of Tucson, AZ via a live camera feed. During this live demonstration, Rohlwing was joined on stage by TIA Compliance Specialist Jeff Faubion and Roy Galyer, training manager for Klinge Holdings.

“There’s only one person that has all the information. That’s the tech on the site,” Rolhwing said. “Nobody else has all the information. We’ve got to make sure that technicians are as prepared as possible and as educated as possible so they’re making better decisions. You’re not going to find everything in the [TIA training] book.”

Matt White, director of tire service for TIA, provided step-by-step training instructions on the RIST procedure and his crew highlighted the importance of teamwork, technology and working the right way to maintain everyone’s safety during OTR service. White has been the director of tire service at TIA for nearly 17 years, an ASE-certified technician, and has been part of the tire industry for nearly four decades.

White explained, “You can see these guys are working in sync and the importance of their PPE here. You can see they’ve got their earplugs in, safety glasses on and using safer tools to get the job done.”

Rohlwing said TIA is continuously looking for ways to update its ETS training. Last year, the organization hosted an Earthmover Tire Service (ETS) stakeholders meeting to get an idea of what needed to be updated in TIA’s earthmover service training. The meeting gathered manufacturers, dealers and veteran “tire guys” to create a blueprint for the future of ETS training.

As a result, TIA released a new, comprehensive update to the 200-Level Basic ETS training, which now includes instruction on how to service one-piece, three-piece and five-piece vertical and loose crane slings and telehandlers. Rohlwing said this meeting will occur yearly at every OTR Conference.

Following the live service demo, Faubion and Galyer discussed the importance of regular training.

“If these guys are taking shortcuts and they don’t know what they’re doing, they don’t know how to do things right, it’s a huge danger,” Faubion explained. “You have to make sure that everybody retains that ability to do the job safely.”

“The more knowledge we can get out there with the tire guys with the stuff that they typically just blow over because it’s easier than asking a question, the better,” Galyer said.

The discussion shifted to pricing structures for tire services, with some companies charging a flat rate and others using an hourly rate. Faubion, Galyer and Rohlwing examined the advantages and disadvantages of each pricing method, with the hourly rate emphasizing safety and accuracy while a flat rate incentivizing speed.

“I think under a flat rate, there’s a pressure to go faster,” Rohlwing said. “Whereas in an hourly situation, the pressure is to get it right and decide what to emphasize. What’s the goal? Is the goal to get it done as fast as possible, or is the goal to get it done correctly and safely?”

“The goal is to teach them not to be fast, but to be thorough and efficient,” Faubion explained. “We want it done right, we want it done well and we want it to last.”