I am sitting in a local tire and service dealer this morning waiting on an oil change and tire rotation. I just moved to the area and this is my first experience at this center. It’s a beautiful place and part of a four-store chain. There are eight drive-through bays on one side, and an express lube on the other with two drive-through bays. They do not accept appointments for oil changes and all services except alignments (first concern). I arrived at 7:30 in the morning when they opened and was the third vehicle in line. It’s now 9:01, and my truck is the next one in line.

I get that people are in front of me, and I chose to wait. What I don’t get is why there are two more vehicles in line behind me and only one oil change bay that is being utilized. There is one person working and two others talking to him. On the opposite side of the store, there are three vehicles in the eight bays and two on the lot waiting for service. One is getting tires and the other two have the hood up, but nobody is working on them, perhaps waiting for parts or approval—don’t know. There are three technicians standing around talking on that side.

Does any of this sound productive? Certainly not in my mind. Why wouldn’t the manager shuffle the vehicles from the oil change side to the open bays and all would be completed inside of 30 minutes? That opens the opportunity to accommodate additional opportunities. It tells me that the flow of business is not being managed.

Effectively scheduling appointments requires knowing your teams’ strengths and weaknesses, and how long it will take your techs to perform the service.

In the tire and service business, we make money through effective selling, controlling expenses and what I call “Bay Productivity.” We focus efforts on pricing tires to make a profit, and we should be watching the monthly financials to make sure that expenses are controlled. But, so often as in the case above, the manager does not spend enough time making sure that the bays are productive. This is the manager’s or service manager’s job. Dealers that make money have mastered this to make sure that each bay is fully utilized where possible, from the time the doors open until closing. This is an essential part of being successful. It all starts with the basics, and below are five tips that will help maximize bay productivity and, ultimately, improve your profits.

Know What Makes You Money

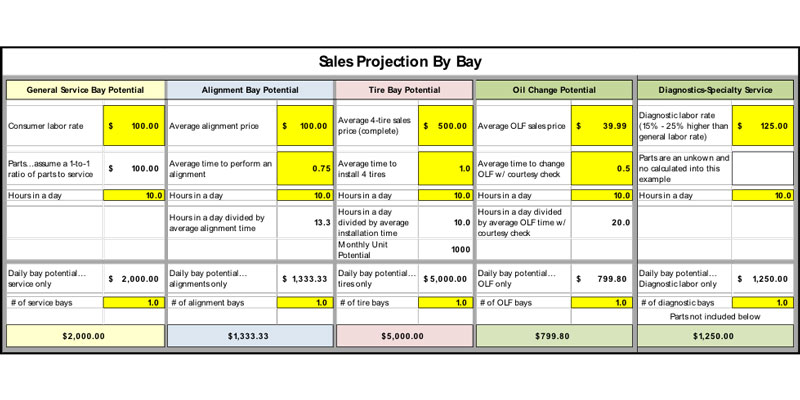

I have found that there are five major categories of work that we perform in our bays (tires, alignments, general mechanical service, oil changes and diagnostics). Each category generates a different level of revenue. Knowing this is the foundation for successfully managing the business flow and staying productive. In the table above, each category is broken out. These are average numbers and will vary, but this should be done in every business to determine the revenue potential and which category will yield the greatest opportunity. In the example above, tires are clearly the best revenue generator, and oil changes are the least. Each segment is important to the overall business but knowing the opportunities will help the overall mix.

Schedule Appointments

Doing business on a first-come basis makes it very difficult to manage the flow. You never really know when customers will walk in the door, and it creates a feast or famine situation. It makes it difficult to manage payroll effectively, affects customer service, limits a technician’s ability to maximize their earnings and limits the volume of business that you can move effectively through the business. This goes beyond writing a name on an appointment pad. Effectively scheduling appointments requires that you know how much time is required to perform needed services (alignments, tires, rotations, oil change, brakes) and use an estimating guide for other services. It also requires knowing your teams’ strengths and weaknesses and how long it will take your techs to perform the service. If your tech can constantly finish the job in less time than allocated, that needs to be considered when scheduling appointments. Knowing this is the foundation for building a productive shop.

Where possible, appointments should be scheduled when they are most convenient for the business. Many customers are flexible and will cooperate knowing that their vehicle will be in and out on a timely basis.

Manage the Flow of Business Throughout the Day

An old friend in southeast Virginia is the master at this. He watches the flow constantly, and he refers to himself as the “Bay Traffic Controller.” Staying on top of this gives him the edge. He knows when the shop is falling behind and where he might be able to slide a “walk-in” customer in. He also knows when a vehicle is hung up waiting on parts and when to allocate a tech to another bay to help pick up the tempo. In addition, he also knows when his tire techs are wearing down. This happens when there is a strong mix of large RV and low-profile tires that weigh more and require more effort. It’s easy to burn them out if you don’t have others jump in to help especially on hot summer days.

Have the Right Tools, Equipment and Working Environment

In this business, it’s been customary that the tech provides their own hand tools. As owners, we provide the lifts, alignment machines, specialty tools, tire and balancing equipment, etc. So, often when I walk through a shop, the equipment is dated and in need of repair. Aside from being a safety concern, having outdated or broken equipment slows down workflow, reducing productivity. Two examples are alignment and tire machines.

New alignment equipment is certainly expensive, and I understand that writing a check is tough. Consider the ROI when making that decision. If an average alignment today takes an hour, that’s 10 alignments a day. If the new equipment can save just 10 minutes, that’s an extra two alignments a day. At say $90 each, that’s $180 a day, or $900 extra per week if you keep the bay full, which goes a long way in offsetting the investment.

The second example is updated tire changing equipment. Again, I know it gets expensive, but if you are working with dated equipment, it makes it difficult to work on the larger rim diameters, RV and low-profile tires efficiently. It also creates safety issues for the techs and can possibly damage wheels.

Maximizing productivity is an ongoing process. You can’t simply sit back and hope for the best. You must constantly review the processes and make improvements where needed.

I would encourage everyone to take some time and talk with their team about improvements that would increase productivity in the shop. Consider where equipment is placed, where tires and parts are stored, whether there is a procedure in place to make sure specialty tools are returned to a central place after every use, and how much time is wasted in walking around looking for something. This is where efficiencies can help improve productivity. Here are some ideas to help spark the discussions:

- Are the tire equipment and tools located near the tire bays? Think in terms of how many steps it takes to complete a four-tire sale. If steps can be saved, productivity increases.

- Are the tires, wheel weights, tire repair items and parts like filters and oil stored in the right location near the bays?

Ensure Employees Are Happy

Practice positive reinforcement: Encourage, motivate and reward. Tell employees they are doing a good job and give constructive criticism. A stressful workplace will not yield results. Workers who constantly operate under highly stressful conditions are found to be less productive and have higher levels of disengagement and absenteeism. This is a tough business and taking the time to show employees how much the company appreciates, respects and values them on a personal level is gratifying — and often overlooked. It can also be tough working in an environment that’s too hot or too cold. Sure this can be hard to control during extreme hot and cold conditions. What we can control is making sure there are fans to keep the air moving and plenty of water when it’s hot, and that heaters work efficiently when the temperatures are cold.

Maximizing productivity is an ongoing process. You can’t simply sit back and hope for the best. You must constantly review the processes and make improvements where needed. There are several companies that have developed software programs that make it easier to track employee productivity and manage the shop electronically with tablets. It will help your employees track their time and improve their earnings. You can see how well they’re doing and where improvements still need to be made.

Practice positive reinforcement: Encourage, motivate and reward. Tell employees they are doing a good job and give constructive criticism. A stressful workplace will not yield results.

Whether you buy into a program or manage this like the “Bay Traffic Controller,” it’s important to understand the difference between following up on your employees and micromanaging them. When you follow-up, you can positively impact their productivity levels. However, when you micromanage them, their productivity levels will fall. As a business owner or manager, it’s up to you to make sure that productivity goals are being met, and when you don’t meet these goals, you must determine why so you can fix the issue. This process will help your employees stay on track and meet your goals.

When following up, try not to be intrusive. This is when micromanaging starts — something that will make your employees feel like you don’t trust them. Employees will then stop showing independent thought because they feel you want them to perform like a machine, which can stifle business growth.

Create a culture of continuous improvement. Improving productivity is a continual process but will produce measurable results and increase your profitability. As an FYI, I finally got my truck back at 9:51 and will think twice about returning.

An industry veteran of 40 years, Dave Crawford is a business consultant and trainer specializing in the evaluation of retail tire businesses for operational effectiveness. He can be reached at [email protected].

Read more from Tire Review’s 2019 Business Planning Guide: Software Systems Drive Revenue for Tire Dealers One Feature at a Time; Business Succession Planning for Tire Dealerships; and Customer Financing Options for Tire Dealers.

Check out the rest of the November digital edition of Tire Review here.