Everything about tires is a balancing act, whether it’s tweaking a compound to make it more wear resistant or determining how tight a bead must be to grip the rim without being too difficult to mount. Choosing the right tire for construction equipment is a similar feat as tire dealers walk customers through a growing number of features and options.

The art of choosing a construction tire comes down to analyzing four factors: machine, load, surface and cycle.

Machine

Despite its versatility, construction equipment is as finely tuned for specific jobs as any other tool on the job site. Loaders scoop and dump trucks haul, so tires that can flex under changing loads and turning wheels are vital for them. Earthmovers and graders demand traction. Skid steers, by design, grind their tires when they turn. Telehandlers and MEWPs—mobile elevated work platforms—require flat footprints and strong sidewalls to maintain stability when the center of gravity is high.

It sounds simple, but be sure to take a moment at the start of this process to think about what the machine you are outfitting actually does all day long and how it moves as it accomplishes its tasks.

Load

Consider the load the tire will bear. A bucket full of sand represents a different weight than the same bucket filled with construction debris, mud or rock. How high will that bucket be raised when it’s full? There’s physics in play—a long arm with a load at the end multiplies the force exerted on the tires. Make sure you don’t under-spec the tires, both when selecting them and when you are determining the appropriate inflation pressure.

Torque from the engine is another kind of load that tires endure. Here’s where sidewall strength and bead really matter. Check with your suppliers to learn about the performance of the bead bundles in your construction tires. In solid tires, creel wires spaced across the entire width of the press-on rim, as opposed to bead bundles only on the edges, has been shown to improve tire—and machine—performance.

Surface

“What is the surface this machine works on?” is often the most difficult to answer. Many may respond, “all kinds of surfaces,” even if a machine actually spends 90% of its working time in a very specific environment.

Here is where two key factors come into play: tread pattern and tread compound.

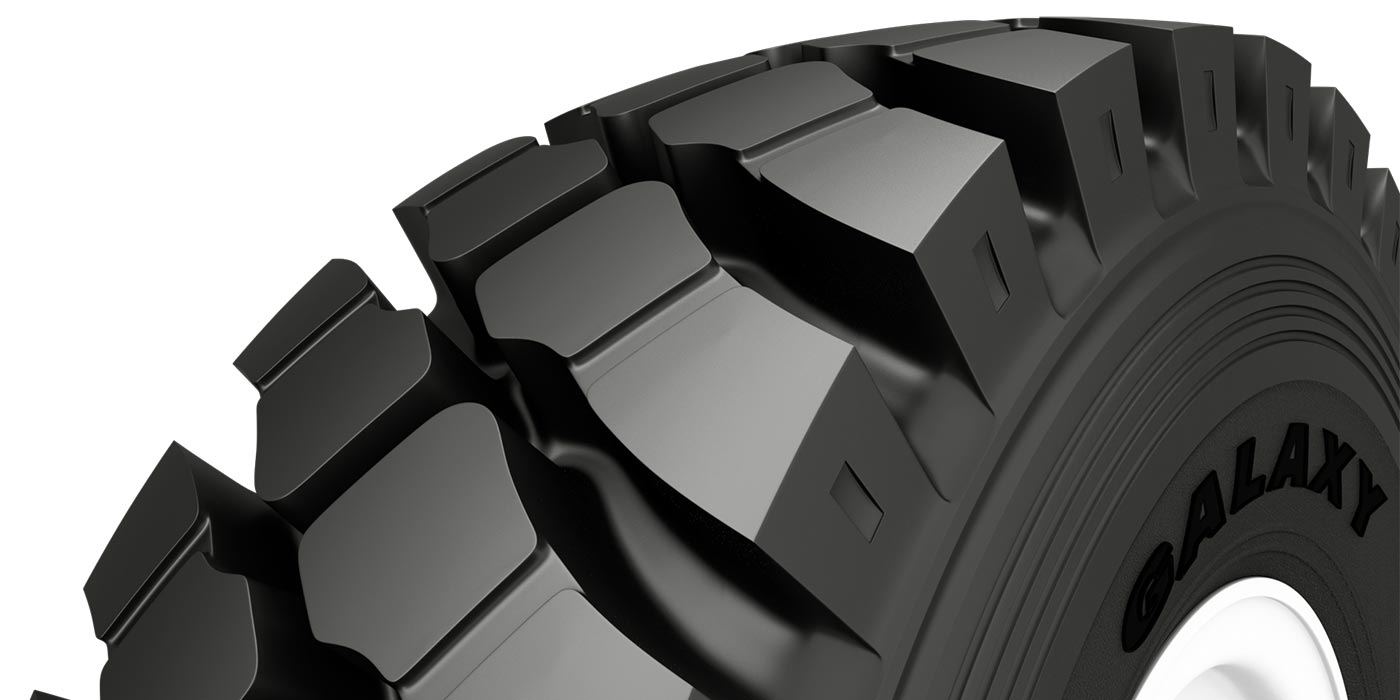

First, consider the tread pattern. An S-shaped rock pattern (typical on E-3/L-3 tires) delivers traction and wear resistance by combining moderately deep grooves with big blocks. An R-1-style curved lug may be right for a backhoe loader that works in sand and mud, while more closely placed R-4 straight lugs combine loose-ground traction with wear resistance for pavement. Where scrubbing and chunking are especially threatening, massive blocks on an L-5 tire are worthwhile, even though you are trading off self-cleaning and heat resistance.

Finally, we have seen great interest in hybrid tread patterns, which combine the smooth ride and extra biting edges of deep blocks with the self-cleaning and traction benefits of curved lugs. As an example, Yokohama Off-Highway Tires even released a siped version of a hybrid pattern tire last year that enhances performance on ice, snow and sand.

Pattern is one side of the tread coin—compound is the other. Some of the most exciting recent advances in the tire industry have been in compound chemistry.

Tires for rim diameters of 25 in. and larger may offer certain tread patterns in more than one compound; for smaller sizes, the manufacturer usually chooses the compound that best complements the particular pattern. Either way, it’s useful to help customers differentiate among the basic categories of compounds.

A multi-use compound provides a good balance of wear resistance, cut-and-chunk resistance and heat resistance for general purpose machinery. Equipment that performs long cycles or spends much time on the road can benefit dramatically from a heat-resistant compound, which tends to be used on patterns with dense centerlines and/or high rubber-to-void ratios that improve roading. Machinery working on rock, broken pavement, demolition or other job sites with sharp hazards are typically protected by a cut-and-chip-resistant compound.

Cycle

As noted above, the distance a machine must cover in a cycle is a critical piece of information for picking an appropriate tire. Heat buildup can become a challenge in construction tires with longer cycles, like a backhoe or dump truck that puts in a lot of road time, especially because the thick carcasses and heavy tread of construction tires are not efficient at releasing heat.

For equipment engaged in long cycles or significant roading, a heat-resistant compound is very important. Those machines can also benefit significantly from radial tires if they are in environments where the risk of sidewall damage is not severe. The flatter contact patch created by the radial construction wears more evenly, encounters less rolling resistance, improves fuel economy and minimizes heat buildup. As an extra bonus, radials also deliver better traction and a more comfortable ride, which can improve productivity.

Solid vs. Pneumatic

Machine, load, surface and cycle can help steer another important decision—whether a particular working environment demands air-filled, foam-filled or solid tires.

Foam-fill in a pneumatic tire can be a useful hedge against downtime from puncture damage. However, a slashed sidewall will sideline a foam-filled tire almost as quickly as the same tire filled with air, so it is important to manage your customers’ expectations for foam.

In severe duty service, a well-constructed solid tire can deliver two or even three times the service life of a pneumatic tire, and offer more features than ever. Today, solid tires are available with a wide range of tread patterns to perform on various surfaces. Options such as apertures and three-stage construction, which combines a highly durable tread compound over a rugged carcass and a cellular core, soften the ride.

Simply put, a solid tire is the most profitable solution for operations that are frequently plagued by punctures, or where downtime due to tire issues is unacceptable. Like any decision about construction tires, the selection among air-filled, foam-filled or solid tires should be penciled out to determine which tire will provide the lowest cost per hour, which can be calculated based on acquisition price vs. hours of service, or the lowest ton mile per hour (TMPH), which factors in variables like heat and distance of travel. Ultimately, the decision is about profitability.

That leads to one last word of caution. It’s tempting to spec the most rugged tire for the worst-case scenario a machine could ever face. But if the extreme scenario is unlikely, then a severe duty, chunking resistant, massive-lug tire probably won’t meet you customer’s need for performance or return on investment. Think of it this way: it’s possible you might get a freak snowstorm on Labor Day, but wearing a down-insulated parka to work in the early fall is probably not a clever, or healthy, choice.

A little time spent thinking about the machine and its job can point you and your customer to a tire that meets—or exceeds—expectations.

Ryan Lopes is national product manager—external communications for Yokohama Off-Highway Tires America, Inc. Combining his perspectives as a mechanical engineer and an MBA, Ryan’s passion has been working with the construction and industrial equipment sector around the world.