Those of you who have been in the industry more than a few years can remember when trucks were loud.

Sometimes this was intentional, similar to when we, as teenagers, spent hard earned money to put dual glasspack mufflers on our hot rods. At other times the trucks just came that way new.

Objections to this noise reached a level such that the federal government enacted regulations during the 1970s and 1980s limiting truck noise as measured by both stationary engine run-up and pass-by road tests. At that time, the three primary noise contributors were the diesel exhaust, tires and cooling fans.

Virtually all highway diesels are now turbocharged and peak sound levels are dampened significantly as the exhaust flow drives the compressor side of the turbine. This reduces exhaust gas pulsing and creates an effective sound damper ahead of the traditional muffler.

Newer trucks equipped with diesel particulate filters (DPF) are further dampened. Acoustic engineering has also been applied to most recent engine block, cylinder head, manifold and intercooler designs to further lower engine noise levels, in spite of climbing torque and horsepower ratings. Engine speeds (RPM) have also been reduced in search of fuel efficiency, reducing noise as a side benefit.

Nearly all cooling fans now operate only on demand to maintain coolant temperatures below set thresholds. Fan-assisted airflow is typically required only at slow speeds combined with high power output, during air conditioning use and/or in high ambient temps. The percentage of time during which the fan is switched on has continued to lessen with newer engine, radiator, charge cooler and hood designs, with most current highway engines having fan-on time in the 5% range.

Tire noise, a complex subject with many components, has also received much attention from product designers and acoustical engineers. And this added attention has resulted in significant and continuing progress.

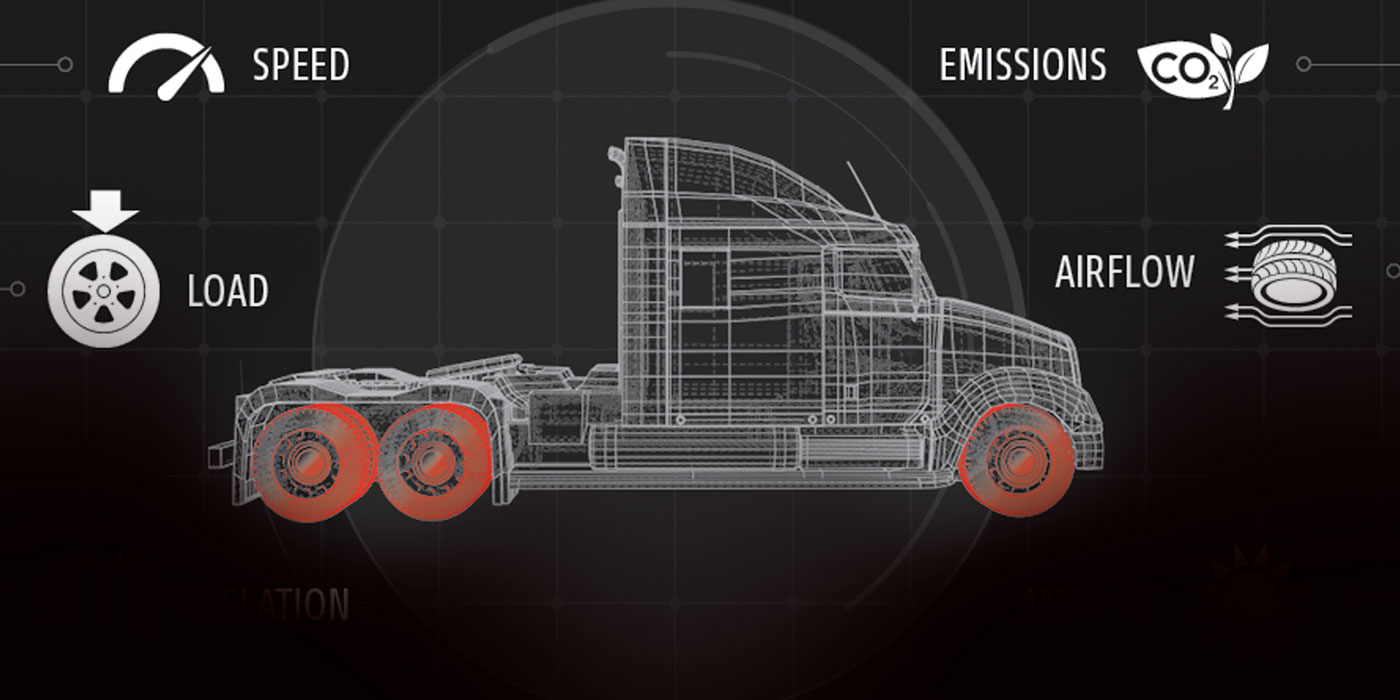

Areas of study include tread element vibration, air pumping, casing vibration and acoustic resonance, among others. Special test conditions, data gathering equipment and a special logarithmic scale (dbA scale) of measurement are used to define noise generation characteristics of new tire designs.

Laboratory tests, using microphones to measure noise at varying speeds and loads, are useful, but as tires become quieter, road surfaces have become a much greater factor. Considering the expected range of “typical” surfaces a tire will run on is an important part of new tire sound level design today. In fact, many new rib tires (steer and trail axle designs) are actually quieter than perfectly smooth tread tires would be on typical high-speed highway pavements.

Generally, asphalt surfaces generate slightly less tire noise than concrete, although the latter usually offer slightly lower rolling resistance to enhance fuel economy.

One method of reducing tire noise used by most new tire manufacturers is called “pitching.” This involves slightly changing the length, usually in a random sequence, of basic tread elements around the tire circumference. This, of course, adds complexity and cost to new tire molds. The bottom line is that some tire treads may look very similar to the untrained eye, but may also have quite different noise characteristics, something to keep in mind when shopping for brand new or retreaded tires.

Another important consideration, relating to maintenance, is that uneven or irregular treadwear nearly always increases tire noise levels. This often occurs before the wear patterns become visually obvious.

Irregular wear patterns such as alternate lug wear, heel/toe wear and heavy shoulder wear are especially prone to increasing noise. The best tire engineering efforts haven’t been able to overcome this tendency. This is an added incentive to maintain proper alignment, inflation pressure, dual tire matching and suspension component condition.

Continuing progress leading to even quieter truck tires is likely. The European Union is well along the way to finalizing regulations which limit noise emissions from truck tires. These are expected to become effective beginning in 2012 for new tire types and apply to all tires in the 2015-2016 range.

Since nearly all radial truck tire manufacturers serving the North American market are global in scope, the technology will likely be incorporated in our tires. Meanwhile, there’s no substitute for traditional good tire maintenance practices and the old adage of “you usually get what you pay for” still applies.

Hino Trucks selects Hankook Tire TBR tires for U.S., Canada truck lineup

Both the AH37 and DL11 are SmartWay verified by the U.S. Environmental Protection Agency.

Hino Trucks and Hino Canada have selected Hankook Tire TBR tires as OE for the U.S. and Canadian markets. The medium-duty truck maker will offer Hankook’s regional AH37 and long-haul DL11 tires on its L Series models.

"As Hino sets the global standard for trucking, it is an indication of Hankook’s leadership in TBR products that our tires will be offered on Hino’s L Series models in the U.S. and Canada,” said Haesik Lee, TB marketing director of Hankook Tire America. “Our AH37 regional-haul truck tire and DL11 regional long-haul truck tire have been built to meet the demands of the modern fleet, with durability, fuel efficiency and tread life at their core. We’re confident in the performance of these products to serve Hino’s U.S. and Canadian customers.”

Yokohama Launches Extreme Traction Tire for Fleets

The 907W tire, which replaces the SY767, carries the 3PMS symbol and is available now in the U.S. in three sizes.

Continental Introduces New Valve Cap Tire Monitoring Sensor

The manufacturer said this sensor works with all of Continental’s digital tire monitoring solutions products.

Continental Launches New Tires for Medium-Duty Trucks

Continental developed the 19.5-inch General RA 2 and RD 2 tires to meet the needs of Class 4 and 5 vehicle applications.

Michelin Launches New Defender Tire Series for Trucks, SUVs

Michelin added two new tires to the Defender line – the M/S2 all-season and the Platinum.

Other Posts

Bridgestone Unveils Greatec M703 Ecopia Ultra-Wide Base Tire

Bridgestone launched the Greatec M703 Ecopia tire for long-haul and regional applications, boasting enhanced mileage and efficiency over its predecessor.

Goodyear Adds Regional Haul Trailer Tire to Cooper Work Series Line

Available in eight different sizes, the new Cooper Work Series RHT 2 is built for regional haul spread axle and tandem trailers.

Sailun Announces Next Generation of Commercial Truck Tires

Sailun Tire Americas introduces new commercial truck tires for fleet managers and owners.

Earn Fleet Customer Trust Via Proactive Truck Tire Maintenance

Asset uptime and safety are major concerns for fleet managers, and tire maintenance plays a key role in both. According to the National Highway Traffic Safety Administration (NHTSA), on average, 11,000 tire-related crashes each year could have been prevented with proper tire care. Additionally, in 2016, tire-related accidents resulted in more fatalities than those caused