Tires are the only component of a vehicle that are in direct connection with the road. Naturally, they are the most important part of the total noise level of a vehicle, both internally and externally.

Vehicle manufacturers like Cadillac, Lincoln, Acura and Lexus are investing millions of dollars to promote their quiet, comfortable drives. Therefore, designing a quiet, comfortable tire for OEM applications is critical.

In this article, we will briefly review the sources of vehicle noise, types of vehicle noise, tire and road interaction, the tire noise mechanism, and, finally, some of the regulations around tire noise.

Sources of Vehicle Noise

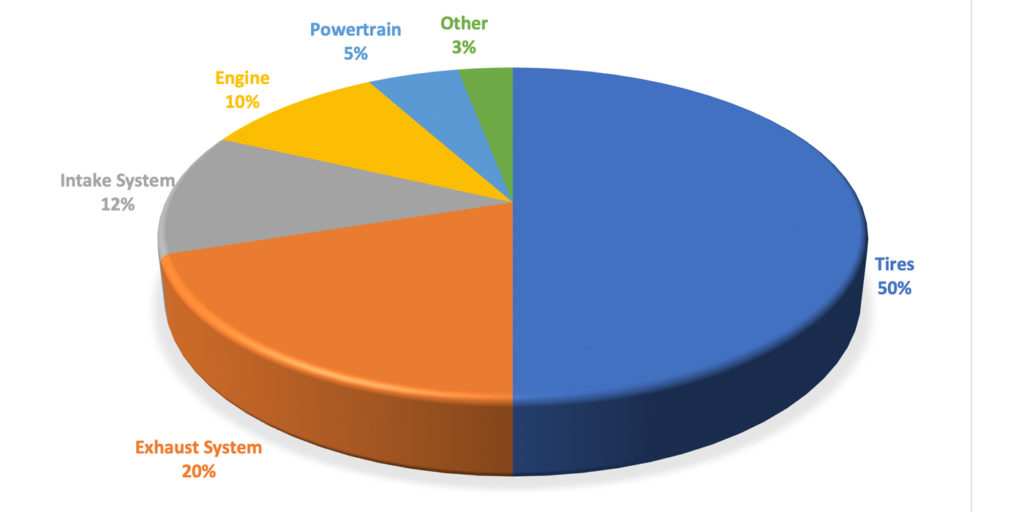

There are different sources in a vehicle that create noise, both internally and externally. Overall, the components that contribute most to vehicle noise include the tires, engine, powertrain, exhaust, intake system, in addition to the aerodynamics of the vehicle. Figure 1 shows the significant effect of each element on vehicle noise. As you can see, tires, by far, are the largest contributor to total noise, followed by the exhaust and intake systems. Therefore, improving tire noise can improve the total vehicle noise overall.

When talking about vehicle noise, we typically refer to interior noise, or noise we hear inside of the vehicle cabin. However, there are two types of noises generated by vehicles.

External Noise

External noise is generated outside a vehicle and affects noise pollution, impacting pedestrians, cyclists and near-by residents. The majority of external noise stems from the tires rolling on the road surface, but it can also be generated by the exhaust, intake system or engine.

As external noise impacts urban life, legislative bodies across the world are sensitive to it. The goal of most government agencies is to minimize external vehicle noise to improve overall urban life. Noise level limits have decreased over the years for almost all vehicle components, including tires.

Driving at lower speeds, smoother/finer material in road surfaces, smaller wheels, narrower tires and quieter engines (i.e. electric-powered engines) can improve vehicle external noise. While those are good measures, designing components such as tires to perform at an optimal noise level is the ultimate solution.

Internal Noise

Internal noise refers to the noise the driver and passengers experience inside the vehicle cabin. The issue of internal noise and how it negatively affects drivers and passengers is something that is a focus for OEMs. Luxury brands, driven by their quiet, comfortable ride objectives, have a very high standard on noise limit. Key sources of interior noise are engine noise, tire/road noise and wind noise, as well as noise from miscellaneous sounds in the interior.

The application of sound-absorbing materials throughout the vehicle, thicker noise-reducing glass, quieter engines (and better sound-proofing between the engine and the cabin in the so-called firewall), softer suspensions with smaller wheels and narrower-width tires can all help reduce internal noise. However, like external noise, designing various components to operate at a lower noise level would be the ultimate solution.

Tire and Road Interaction

Improvements on road and tire design have reduced the total noise level of tires in the past decade. In the highway and road markets, transitioning from common stone to porous asphalt reduced the noise level. Breakthroughs on prediction tools and optimizing the tire pattern by computer have driven tire noise to the lowest levels ever.

As you can imagine, the quietest tire is a smooth tread where no impact between the tread blocks and the road exists. The closer the tire pattern gets to a completely smooth tire, the quieter the tire gets. Tire manufacturers were able to reduce overall tire noise by 5 to 8 dB in the past 10 years. In some cases, modern tires have only 2-3 dB higher noise than smooth tires.

While those improvements significantly reduced overall vehicle noise, tires remain the focal point of the majority of noise generation at higher speeds, so constant improvement is required. In order to improve a tire’s noise level, it is important to understand a tire’s noise mechanism, both internally and externally.

Tire Noise Mechanism

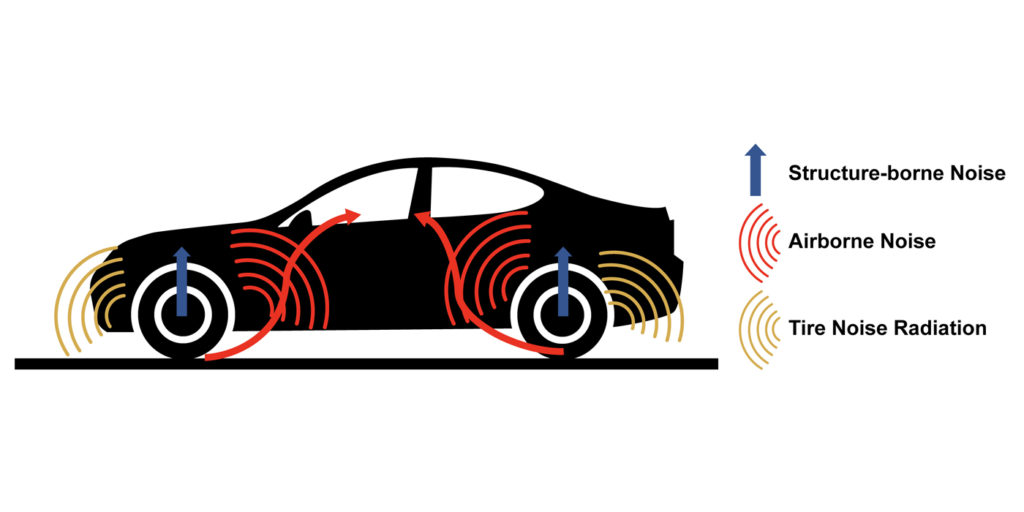

Interior noise is transmitted inside of the vehicle through its structure and via air. Airborne noise consists of the progressive movement of mass particles (vibrations) and is transmitted in the form of soundwaves at the speed of sound to the vehicle cabin. Structure-borne noise is transmitted through the body of the vehicle through the tire. Exterior noise is transmitted outside through radiation and sound waves. See Figure 2 that illustrates the difference between structure-borne noise, airborne noise and tire noise radiation.

The frequency of structure-borne and airborne noises shifts as the dominant inside noise as the result of changes in the vehicle’s speed. At lower frequency, normally at lower speeds, the structure-borne noise is the dominant type of noise. At a higher frequency range, normally at higher speeds, the airborne noise is the dominate type of noise.

Structure-borne noise is normally around 160 Hz and is influenced by tire construction. Airborne noise is normally around 1,000 Hz and is influenced by a tire’s tread pattern. Table 1 on page 23 shows the type of interior noises, as well as frequency range and the area of the tire that affects the noise.

External noise transmits at any speed and increases as the vehicle speed increases. This means that as speed increases, overall noise increases, which includes noise from a vehicle’s tires, powertrain and aerodynamics.

External Noise and Regulation

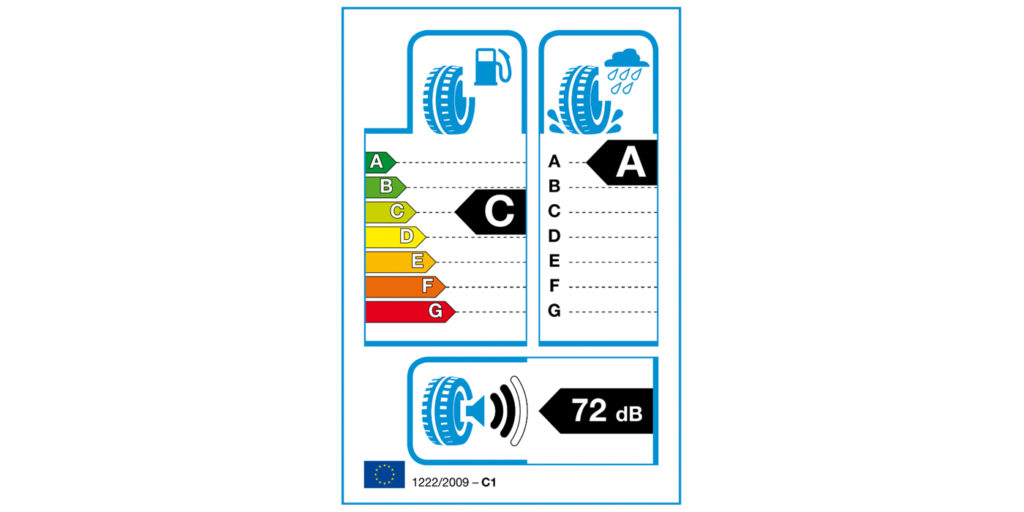

As discussed earlier, external noise impacts urban life. Noise regulation is different in each country. The European Union (EU) tire labeling regulations for passenger car and light truck tires, for example, went into effect November 1, 2012. This information helps consumers make a conscious decision during the tire purchase (see the European Tire label in Figure 3). The label consists of three criteria: wet braking (A), fuel efficiency (C) and pass-by noise. While a lot of people think the noise level on the label is an indication of indoor noise, it actually indicates noise pollution or external noise measured by a pass-by noise vehicle test. A tire rated one wave is half as noisy as a tire rated with two waves. Pass-by noise is measured from the sides of the road with a vehicle traveling 50 mph (80 kph) with the engine switched off.

The number of black waves in the speaker reflects the noise severity of the tire. A speaker with one black wave is normally an indication of a quiet tire. A speaker with two black waves demonstrates a tire with a moderate level of noise, while three waves coming out of the speaker is an indication of a noisy tire.

Noise levels are established by size, with narrower tires challenged by lower targets than wider tires. While the dB level is quantifiable, the tire’s ability to comply with EU regulations (number of sound waves) can be compared only between tires of the same size.

While there is no country-wide tire noise regulation in the U.S., most of the tires sold here carry the European E-mark, which is an indication of lower noise levels.

Final Thoughts

Tire noise is a very complex matter normally managed by a team of experts within tire companies who are experienced with NVH (noise, vibration and harshness). Because tire noise levels change internally and externally with the speed of the vehicle and the transfer through different sources, detecting and improving tire noise difficult. However, with the advancement of prediction tools and a better understanding of noise sources, today’s tires are much quieter than their predecessors. Developing the next level of noise reduction will be challenging, but the industry is committed to providing the quietest tire—both internally and externally—to the market.