In the business of automotive repair, two of our primary goals are always increasing the efficiency at which our technicians can perform service and increasing the opportunities for service that we can offer our customers. The Autel ITS600 can help us do both.

The Autel ITS600 is a wireless TPMS tool that offers complete TPMS diagnostic and service functions. With its ability to activate, read and relearn all known TPMS sensors, the ITS600 will provide your technicians with comprehensive TPMS service capability, but when utilized with Autel’s programmable 1-Sensors, it can also expand the scope of your service offerings.

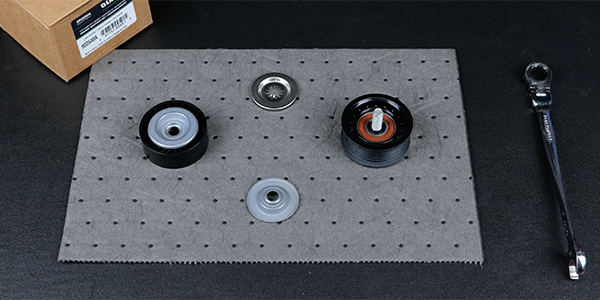

Autel 1-Sensors are programmable universal sensors that are designed to perform specifically like OE sensors. They support over 90% of North American, European and Asian vehicles and their coverage hits over 98% of all OE sensors on the market. They are offered in both the snap-in and clamp-in designs, and due to their coverage, they can also simplify your inventory management.

When using the 1-Sensors, the ITS600 gives technicians four different options for programming them, and to demonstrate the ease as to which this can happen, we’re going to review one of them here – the “copy by OBD” method.

Here’s how it works: Once you have the ITS600 powered up and the wireless VCI (vehicle communication interface) connected to the DLC (data link connector), the first step, as with many of the TPMS features, is on the TPMS Status Screen. The ITS600 will automatically confirm the VIN or you can use the VINscan camera feature to easily grab the vehicle data off the driver side door jamb.

When it’s time to program the sensors and you’re using the copy by OBD method, the ITS600 must read the sensor IDs from the vehicle ECU. To do this, from the TPMS function menu, select the diagnostics tab, and the registered sensor IDs will be shown in the second column.

The next step is to select the programming tab and select the sensor location that you want to copy. Place the new Autel 1-Sensor in front of the ITS600 and select “copy by OBD.” It will ask you to confirm that you want to program the sensor. Select “OK” and the registered sensor ID will be copied to the new 1-Sensor. That’s it. It’s that easy.

Utilizing an Autel 1-Sensor and the “copy by OBD” method on the ITS600 is a great way to efficiently program a new sensor, and if you have a vehicle with a damaged sensor, this gets the job done quick, gets your customer back on the road and your technician on to the next job.

It’s also a great way to set up an extra set of sensors to match the current sensors on a vehicle. More and more common all the time, people are getting an extra set of wheels with winter tires, or they’re getting a set of wheels and tires just for the summer. No matter how you look at it, it’s a year-round opportunity for sales.

With the Autel ITS600, the 1-Sensor, and the “copy by OBD” method, you can confidently offer this service to customers, and when they change over their wheels, they’ll retain full and correct TPMS function without the need for any additional programming.

And don’t forget, with any car, the ITS600 can produce detailed reports of diagnostic, inspection and service recommendations that can be printed or easily emailed to the customer.

The ITS600 has a host of other “add-on” tools that can be used with it to provide your customers a more detailed examination of the health of their vehicle and a scan report that is easy to read and understand. Let’s take a look at the TBE200.

The Autel TBE200 is a laser-enabled tire tread depth and brake disc wear tool that provides users with quick and accurate wear measurements. Measure brake disc wear without having to remove tires. It features a 1.65-in. Amoled super retina touchscreen, displaying measurement data curves in real-time. TBE200 provides uneven wear analysis and detailed replacement and maintenance suggestions for quick tire service. The TBE200 dual cameras enable users to document tire wear and damage and scan Tire Identification Numbers. Use the tool separately, or with ITS600 to view and print detailed TPMS reports. You can even test the brake disc wear with the same tool without removing the tires!

The comprehensive report from these tools will include TPMS health, tire tread depth, brake disc wear characteristics and repair tips when paired with the ITS600. Detailed replacement and maintenance suggestions are easy to read and understand with some of the results suggesting a tire or brake disc replacement, tire rotation and alignment servicing.

The data can be printed and presented on a scan report that can be printed or emailed directly to the customer or generate QR codes for tire tread depth and brake disc measurements to allow for easy report sharing & download via mobile phones or tablets.

All this information was collected without even removing a tire! In a matter of minutes, you can diagnose a failed TPMS sensor, uneven tire wear indicating an alignment check is suggested and maybe even some rear rotors that are getting worn. This tool can help keep your customers safe and informed about their vehicle without sacrificing valuable time from your technicians.