When it comes to tire repairs, there’s no room for cutting corners. Every skipped step can lead to improper repairs and issues for customers’ tires down the line. For your shop’s safety and reputation, meticulous technique during tire repair is a must.

Brent Blackburn, national accounts sales manager at Myers and Rich Watts, tire repair consultant at Myers, talk about why a high level of care is just as important for techniques used during the tire repair process.

“You can’t cut any corners,” Blackburn said. “You know why? Because the guy you trained is going to find a way to cut another corner. Shops may have three or four generations of people who have been trained, and each one of them is smarter than the other when it comes to skipping steps. The next thing you know, they’re missing three or four steps and they’re not repairing right at all.”

He stressed the importance of taking pride in all repairs you do at your shop and explaining to customers that just because repairs may take some time, it doesn’t mean you’re wasting theirs. It’s the opposite – explain to customers the importance of taking time to repair punctures. Feature visible wall charts on proper repair procedures and clear guidelines from manufacturers so you can explain how and why the industry dictates your shop’s standards of what’s repairable or not.

Watts said you have to sell and promote tire repair just like any other service you do at your shop.

“You have to sell a tire repair like you sell a brake job or an alignment job – you have to make it important to the customer,” Watts continued, “Stop acting like it’s just a round black piece of rubber with a hole in it that can be fixed with a string plug in it. Why would you not properly repair a tire a customer may spend hundreds of dollars on?”

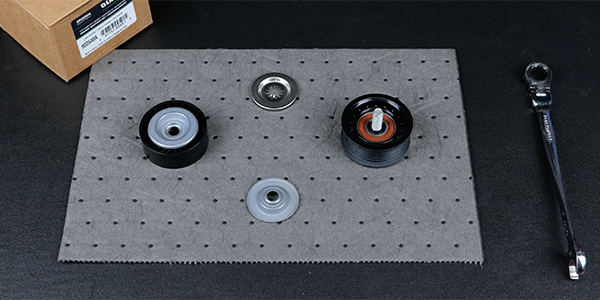

Myers said the standard repair process should go something like this: first thoroughly inspect the tire interior and exterior before demounting. Then, mark the injury location on both sides of the tire. Use a carbide bit to remove the injury and make it a circle that has no weak point. Then, Myers recommends using a buffer at the proper recommended RPM to buff the inner liner. After that, apply the cement and let it dry adequately. Install a one piece patch/plug unit or a two piece repair with a plug and patch if the angle of injury requires it.

Using quality repair materials like Myers Tire Supply’s comprehensive “Do It Right” tire repair product line is equally essential. The right cement, patches, plugs, bits and sealers from Myers ensure each repair meets manufacturer standards.

By methodically following each step of the tire repair process, safely restoring punctured tires and preventing comebacks, dealers create trust and loyalty.

Blackburn emphasized taking pride in the work and being able to tell the customer, “I care enough about you and your family’s safety to do this right.”

With comprehensive tire repair knowledge, precise techniques, and top-quality materials, your technicians can safely get customers back on the road while building a reputation for excellence. Myers Tire Supply provides all the necessary tools and training to set your shop apart.

Sponsored by Myers Tire Supply.