Since the first days of the automobile, people had the desire to drive farther. Along the way, our industry invented bigger fuel tanks, more durable and powerful engines and, eventually, “flat-free” tires to overcome the challenges inherent to driving farther.

Flat-free is not a new concept. The idea goes back to the 1930s when engineers inserted fabric inside the tire to extend the driving range after a flat. Later on, engineers attempted to insert a metal ring inside the tire to extend mobility after a puncture. Then came the application of a sealant inside the tire, and, eventually, we came to the more modern run-flat construction that many manufacturers utilize today.

This article will briefly review the run-flat market, the extended mobility concept and, finally, the science behind run-flat tires.

Run-Flat Market

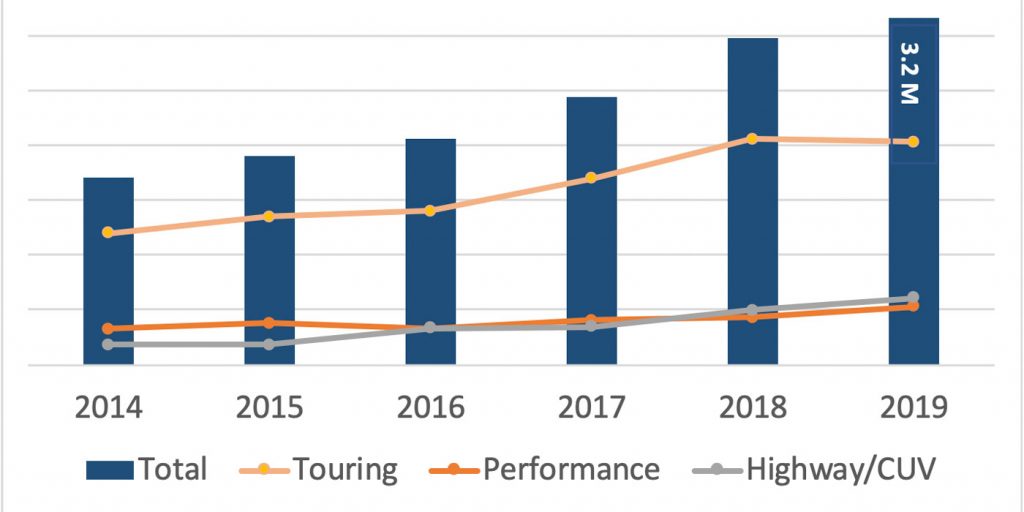

With the advanced development of run-flat technology and dedication of a few car manufacturers to the technology, run-flat tires have seen a dramatic increase in volume. While the market is only 3.2 million tires, the unit volume has increased 100% over the past 10 years. (See Figure 1 for run-flat tire market size and segmentation.)

The touring segment, with H- and V-speed rated tires, comprised around 47% of the total run-flat tire market in 2019, followed by CUV/highway tires with around 19% of the market. (See Figure 1 for run-flat tire market size and segmentation.)

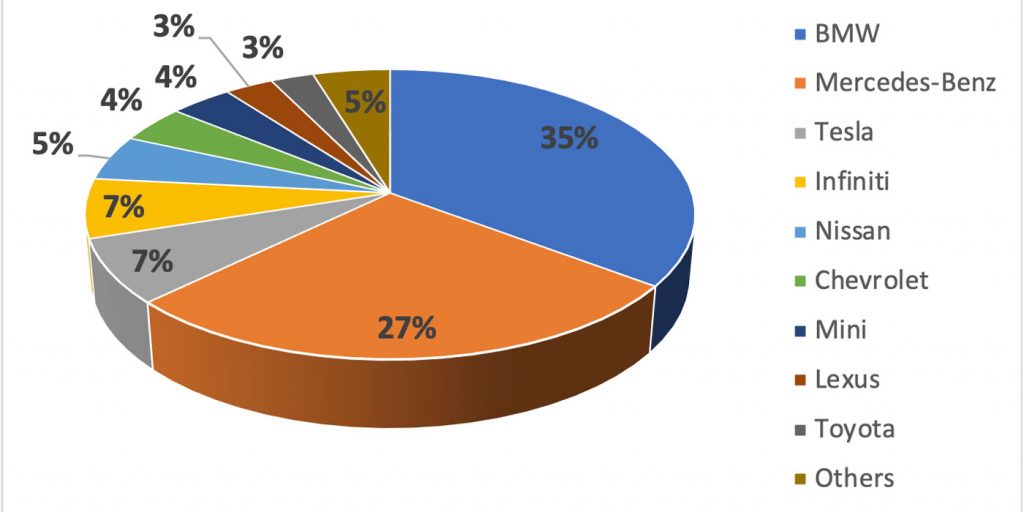

Without question, BMW has most embraced and advanced run-flat technology in its automobiles (see Figure 2) among OEMs. Starting in 2000, BMW debuted the stylish Z8 with a staggered set of 18-in. run-flat tires. Soon after, in 2002, the Mini brand launched with 100% run-flat tires featured on the Mini Cooper models with 16- and 17-in. rims. By 2004, BMW featured run-flat tires on the 3, 5, 6 and 7 Series automobiles, as well as the Z4. Lexus was also out of the gates early with a run-flat fitment on the SC Coupe in 2000 and has followed with run-flat options on many vehicles since. And, of course, Chevrolet’s Corvette was a groundbreaker, offering run-flat tires as an option in 1994 and as standard equipment beginning in 1997. In 2019, many auto manufacturers offered vehicles with run-flat tires, but BMW and Mercedes-Benz dominate market share.

Extended Mobility

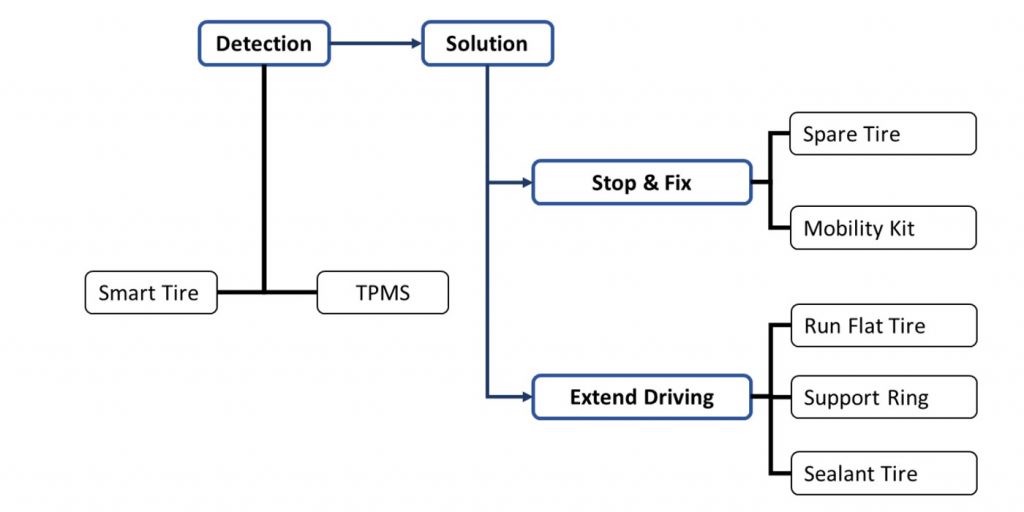

To better understand the reason run-flat tires were made as a mobility solution, we must look at the mobility system. This system has two phases: detection and solution. (See Figure 3 for the total extended mobility system.)

Phase 1, or Detection, is key for a mobility system to function properly. This happens when a sensor that detects pressure loss helps the driver understand the situation, and the driver adjusts their driving to match the circumstances.

During the detection phase, the tire pressure monitoring system (TPMS) indicates that one or more of the tires on the vehicle is at least 25% below the recommended pressure. Today, almost all vehicles are equipped with TPMS. In recent years, additional sensors have been added inside tires, which provide additional information such as tire temperature and footprint information for enhanced driving performance.

In Phase 2, or the Solution phase, there’s a few options for how the driver can work with the system to correct the problem.

Option 1: Stop & Fix

For years, the solution to a flat tire was a spare tire. A spare tire is still the most reliable solution that exists to date, but With vehicle space at a premium, especially on smaller sporty cars, a solution other than a spare was needed, and the mobility kit was born. Mobility kits are great solution since they occupy a small space, are easy to use and efficiently address the issue in a short amount of time. The majority of mobility kits were developed with two stages: fix and inflate. In the fixing stage, a sticky rubbery sealant is injected into the tire. In the inflate stage, the tire will be inflated to the recommended pressure for the vehicle with the included air compressor. The centrifugal force of the wheel spinning while driving should press the injected material into the puncture and seal it. While mobility kits are great for space and ease of use, it cannot fix a sidewall puncture. It will often ruin the TPMS sensor and, in most cases, the tire cannot be used again.

Option 2: Extended Driving

Stopping on the shoulder of the road to change a tire or use a mobility kit always poses a risk. Over the years, several concepts have been created in an attempt to avoid this, such as using a sealant or a supporting ring.

A sealant is applied inside the tire at the final stage of production. In the case of a flat, the sealant will flow to the hole and prevent further leakage. It’s a great concept, but it will fix a flat only on the tread area and is not effective if the tire has a sidewall puncture. This method also adds complexity to tire production as it adds a new and very time-consuming step to the final product.

Another device designed to avoid tire deflation after a flat was a supporting ring, which manufactureres inserted during production. While the concept fulfills its intended role, it adds weight to the tire assembly and compromises rolling resistance, ride and comfort. The self-supporting ring is also very costly and makes the tire difficult to mount and dismount.

Option 3: Run-Flat Tires

A solution that allows drivers to continue driving while avoiding tire deflation after a puncture—and also not damage a wheel—is the run-flat.

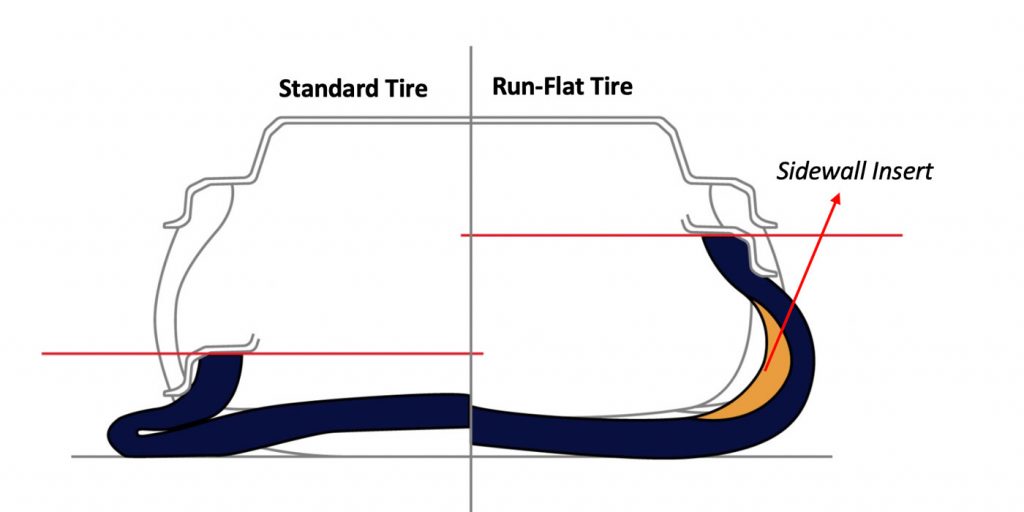

Run-flat tire technology is based on a reinforced sidewall that is self-supporting. In the case of a puncture, a sidewall insert prevents the sidewall from being crushed between the rim and road or from slipping off the rim (see Figure 4). A run-flat tire makes it possible to continue driving with zero air pressure for up to 95 miles with a maximum speed of 50 mph.

Figure 4: Run-Flat Tire (Courtesy of Yokohama Tire)

Run-Flat Tire Development

Tire development is always focused on designing for four key elements—pattern, contour, construction and compound (material).

The majority of run-flat tire development is devoted to developing materials and construction. Engineers should develop a reinforced sidewall insert to support vehicle weight at high-speed driving with little compromise to other performance indicators. While the sidewall insert improves run-flat distance, it also increases vertical tire stiffness and, as a result, increases tire wear and reduces ride and comfort. Contour and pattern will be used to achieve other characteristics and optimize the overall performance.

Compounding/Material

The most important target conflict in run-flat tire development is ride and comfort. With the improvement in run-flat distance, the ride and comfort will be compromised. With a traditional compound insert on a run-flat tire, ride and comfort increase as the distance a run-flat can travel decreases. With newer compounding technology that improves the tradeoff between run-flat distance, ride and comfort, the goal for the future is to flatten as engineers are able to provide closer to optimal tire performance by maximizing mobility with little ride and comfort degradation.

Construction

When a flat occurs and a tire loses air, the sidewall insert should provide the vertical stiffness to avoid the tire’s collapse. At the same time, the bead and apex should be able to maintain proper seating with no- or low-inflation pressure. Optimizing sidewall insert thickness is key to providing the required run-flat distance with a minimal increase on vertical stiffness for better ride and comfort.

Apex height and shape, along with the size of the bead, are the other two important factors for maintaining proper seating and improving the run-flat tire target conflict.

Final Thought

Consumers’ love of motoring and the ever-present desire to go out, drive further and drive safer has created a need for continuous tire improvement and innovation—and the impact of run-flat tires through the years cannot be overstated. Over the years, engineers have relied on experience, new information, new materials and new construction techniques to better solve those problems. Today’s run-flat tires have far fewer compromises than the pioneering run-flats of 20-25 years ago. And knowing the scientific advancements made during that time, it’s easier to imagine a not-so-distant future in which run-flat tires could provide an optimal blend of comfort, performance, mileage, safety and peace of mind.

Check out the rest of the June digital edition of Tire Review here.