When times are tough, the retread industry shows its true colors. We’ve clearly seen that over the last two-plus years when manufacturers, owners, plant workers, front office staff, you name it… have all stepped up during challenging times to deliver for their customers when it mattered the most.

We can see the impact those efforts had on the retread industry in 2021 as retreaded commercial truck tire shipments grew to 16 million units, a 14% increase over 2020. This year, some of the challenges started to recede a bit, but retreaders didn’t take their foot off the gas and continued to deliver strong growth. Let’s take a look at some of the factors currently influencing the retread industry as well as look forward to future changes we can expect.

Supply Chain Issues

Ports were clogged, drivers at the ports were scarce and container costs were doubling every couple of months. This made bringing in raw materials and casings a challenge for retreaders, but it also impacted the supply of new tires. Retreaders quickly shifted to balance the needs of the customers and worked to get them the products they needed. At the same time, retreaders partnered with customers to explore maintenance options to protect investments in casings and improve the number of retreads per casing.

Rising Costs

Not only were freight costs going through the roof, but costs for everything else like raw materials, fuel and wages, etc. were rising. New tire manufacturers were forced to raise prices multiple times over this period and even with some increases in retread prices, the cost difference between a new tire and retreaded tire continued to grow. Throughout its long history, the retread industry has always been counter-cyclical. In an inflationary environment with higher prices, fleets turn to cost-saving measures including adopting or increasing the usage of retreaded tires. Smart fleets realize the cost benefits of retreading are significant and stick with it when the economy gets back to normal.

Labor Challenges

When I ask our members what their three biggest challenges are, many of them say, “People, people and people.” Finding, hiring, training and keeping good people has taken up an increasing share of retreaders’ time. During the early stages of the pandemic, retreaders had to keep plants operating while taking care of employees and managing operations when multiple employees were out sick. Cross-training, working overtime and changing shifts were a few of the ways the employees and employers stepped up to keep the tires rolling and fleets moving. Many retreaders I’ve spoken with have echoed the same sentiments: “The demand for retreads is so high that if I could get more material and more people, I could be selling a lot more product.” As we’ve moved through 2022, inflationary pressures are also causing retreaders to look at their wages and benefits to remain competitive and attractive employers in their region.

Consolidation

We’ve seen an acceleration of mergers and acquisition activity in the retread industry in the last eighteen months with some of the biggest players getting even bigger. Southern Tire Mart, Pomp’s, BestOne, McCarthy, Purcell, Wonderland — the list of retread companies buying or being bought continues to grow as we finish out 2022. This consolidation allows for increased efficiency in plants, wider service networks for customers, and an increased range of products for retread customers as well. However, those consolidations also come with their own sets of challenges in terms of integrating systems, operations, as well as cultures. As borrowing costs continue to rise, it may have a cooling effect on the M&A activity within retreading, but I know some of our members are still exploring the right opportunities to continue their geographic and product-line expansions.

Environmental Emphasis

Retreading is among the greenest of green industries with massive amounts of environmental savings in raw materials, (oil, natural rubber, steel), reduced carbon emissions and landfill avoidance for millions of tires. Increasingly, companies of all types are setting environmental and corporate social responsibility targets for themselves and are working with tire partners to help them meet their targets. While some fleets are focused on alternative fuels, improved aerodynamics, and low-rolling resistance tires, many of them are realizing they are sitting on a gold mine of improved environmental savings just by adopting or increasing their usage of retreaded tires in their operation.

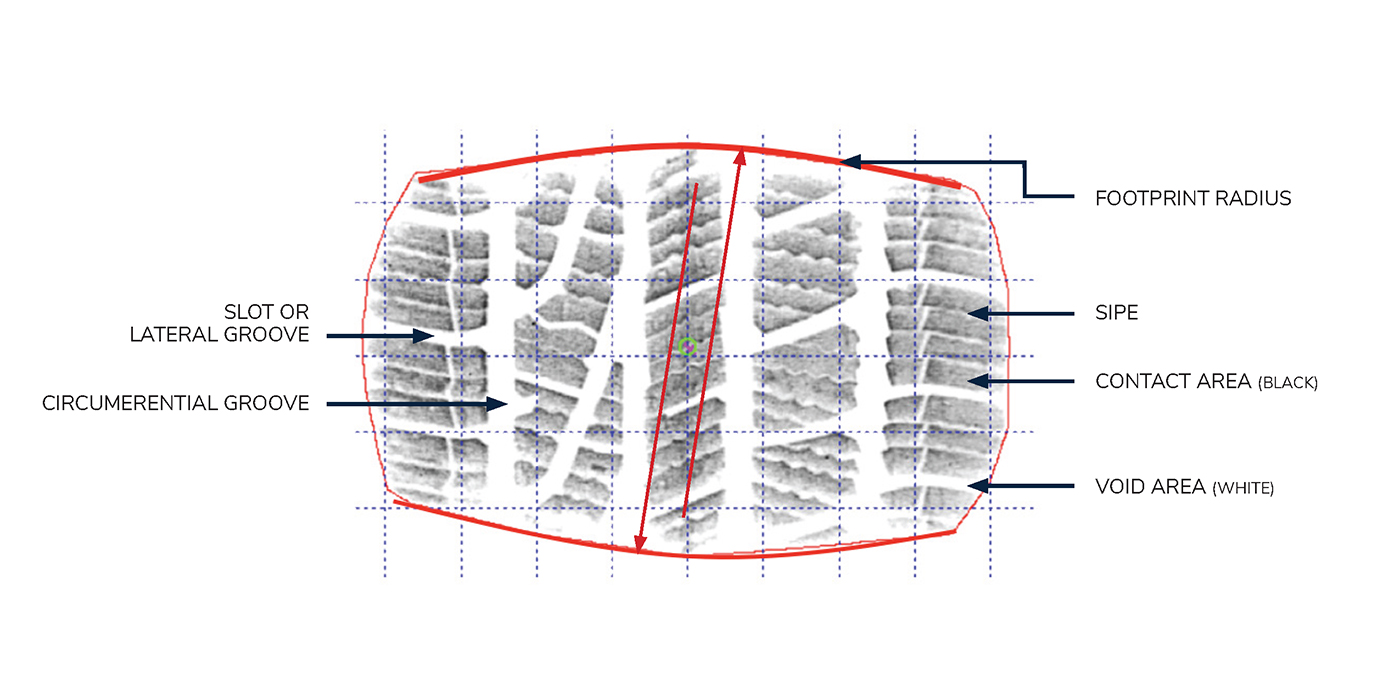

So, what do we see for the retread industry moving forward? Many of these same challenges and opportunities will present themselves in 2023. A challenging, possibly recessionary economy will keep fleets focused on cost-savings; while increasing freight demand, especially with last-mile delivery, will keep retread plants busy. Supply chain issues will hopefully start to ease, but this also increases the likelihood of competition from Tier 3 and Tier 4 new tires. New tire manufacturers and retreaders will continue to be focused on emerging new products in the industry including non-pneumatic tires (an exciting prospect for retreading since under-inflation is a primary cause of casing damage), tires for electric vehicles that can handle their increased weight and torque demands and smaller-sized retreads for the growing last-mile delivery segment. Retreaders will continue to focus on ways that smart automation in the plant can improve efficiency and quality while also easing human resource concerns. The increased collection, analysis and sharing of tire data with retreaders’ customers will continue to be important, as will ensuring that data is secure from outside parties. Lastly, continuous improvements in casings, tread designs and tread rubber compounds, increased use of recycled materials, and improvements in inspection technology will all keep pushing the retread industry forward.

Times may be tough, but retreaders are tougher and are well-positioned to take advantage of the unique economic and environmental situation we all face.