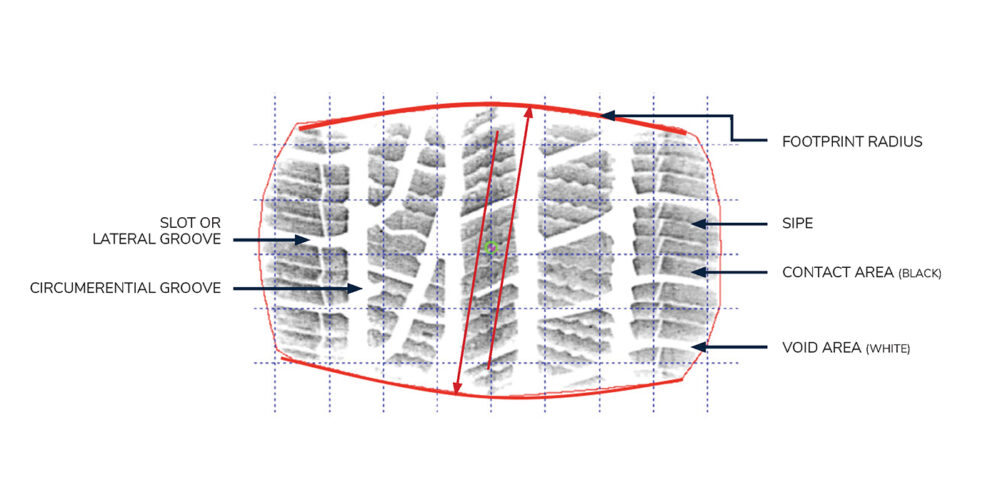

Virtually every element of the tire tread, from the number and size of lateral grooves to the overall void area to the radius of the contact patch, can be optimized for specific driving conditions. Understanding the relationship between tread design and tire traction, especially for specialized driving conditions, can be valuable when educating customers on the differences between all-season and winter tires.

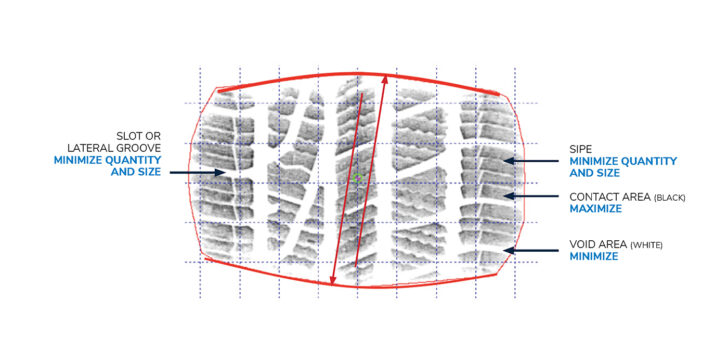

Optimizing tread design for dry driving conditions

Dry traction generally refers to traction on an asphalt or concrete surface under ideal conditions, with no risk of slippage due to water, snow, or ice. A tire optimized for dry traction will be designed to maintain contact with the road surface when the tire rotates. There are a few specific engineering and design strategies that can facilitate this:

- The contact area of the tread is increased, while void areas, such as grooves, slots, and sipes, are decreased.

- The tie bar is maximized to minimize squirm in the footprint area.

- The depth of the tread is decreased.

- The tread compound is optimized for dry traction based on the physical design of the tread compound.

Racecar tires provide an excellent example of a tire tread that has been optimized for dry traction to an extreme degree. Race tire treads have very high contact areas, with very few voids, and premier raw material technology for maximum performance for wet and dry traction. The technology utilized in race car tires is eventually transferred to passenger car and light truck tires.

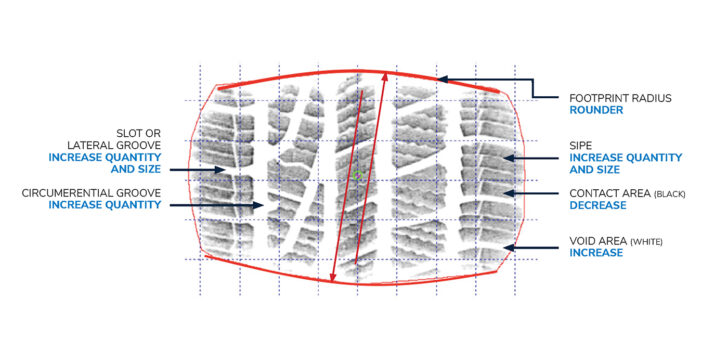

Optimizing tread design for wet driving conditions

Wet traction refers to traction on a wet road surface, usually asphalt or concrete. The performance of any given tire under wet traction conditions can differ significantly depending on the depth of the water, the speed of the vehicle, and other variables. An extreme example of wet traction loss is hydroplaning, a phenomenon in which a tire completely loses friction and contact with the road surface.

A tire optimized for wet traction will be designed to evacuate water from the footprint area as quickly as possible so the tread can maintain contact with the road surface:

- The depth of the tread is increased.

- The size and quantity of void areas are maximized. Circumferential grooves are made larger, as are lateral grooves in the shoulder and intermediate ribs. All ribs have more, larger sipes.

- Tie bars are minimized to avoid constraining the slots and shoulder grooves and inhibiting water evacuation.

- The tread compound is optimized or developed for wet traction performance.

It’s worth noting that wet traction optimization strategies in terms of tire pattern design are contrary to those employed when striving to optimize for dry traction.

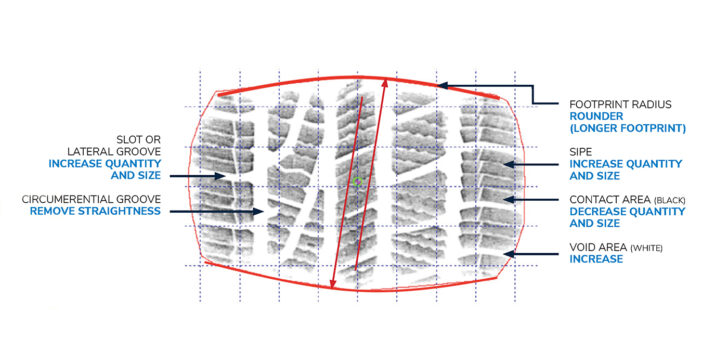

Optimizing tread design for snow driving conditions

Snow traction refers to traction on snow-covered surfaces. There are countless variables that can affect snow traction performance, including snow depth, compaction, and structure, such as fresh flakes versus hardened crystals. Snow conditions can vary dramatically throughout a given winter season or even a given day.

While dry and wet traction are determined by the ratio of surface area to void area, snow traction relies on the abundance and density of biting edges in the tread that can grab the snow. There are several strategies to consider for maximizing biting edges:

- The contact area is decreased, the void area is increased, and tread depth is maximized.

- All lateral structures are maximized. For example, sipe quantity and size is increased in all five ribs of the tire.

- Tie bars are minimized to reduce the constraint of elements and allow for squirm and more deformations that produce biting edges.

- The tread compound is designed for improvements in snow and ice traction. Specifically, the tread compound is formulated for lower durometer and lower static/dynamic modulus to allow for greater flexibility throughout the tread in cold temperatures.

What about all-weather or all-season tires?

Some people faithfully switch to winter tires every year when the snow starts to fall. But in climates that only experience mild or occasional snowfall in winter, this may not be necessary. And of course, switching to a designed wet traction tire every time it rained would be incredibly impractical, even if such a specialized tire existed. The most sensible, convenient, and cost-effective option for most drivers is to drive on all-weather or all-season tires year-round.

All-weather or all-season tires are designed to perform reliably in a wide range of conditions. However, the tread design strategies for optimizing tire traction performance for one set of conditions are often the exact opposite of the strategies for another set of conditions. This requires tire engineers to make design decisions in order to develop a tire tread that performs well in a variety of driving conditions, even those demanding different strategies for traction performance optimization.

Testing during the research and development stage is critical for designing all-weather or all-season tire treads. Tire engineers can objectively assess the performance of different tire tread designs in a controlled environment to determine which design is best for year-round use. Testing methods include compound development and machine-mounted testing in a laboratory as well as on-vehicle testing on a designed track.

Why this matters for independent tire dealers

Understanding the nuanced differences between different tread designs can be valuable for communicating the value of different tire options with customers. This is especially true when discussing snow tires. As previously mentioned, all-season and all-weather tires are appropriate for many drivers, but in some climates, winter tires can be the more appropriate choice. If a customer is hesitant to spend money on specialized tires or wants to learn more about how winter tires differ from all-season or all-weather tires, dealers can explain the unique characteristics of winter tire tread design and how it translates to better traction on snow-covered roads. As a result, the customer has a greater understanding of the tire’s value and greater confidence in the dealer’s expertise, which may result in more sales.

Josh Guilliams is the vice president of consultancy at Smithers.