I was never much of a football player, which is not easy to say being a 5-9 kid from Canton, the cradle of pro football and the heart of Ohio high school football.

My football career (and I use the term loosely) never amounted to much, but there was a piece of advice my high school coach, Don Hertler Jr., used to repeat to us. “Nothing is ever as bad as it seems and nothing is ever as good as it seems.”

In my last article, I talked about a newer breed of ag tire classification called IF (commonly referred to as “increased flexion”) and its cousin “super flexion technology.”

Who cares, right? Well, it’s important because it allows today’s generation of farmers to do more with less. In fact, up to 40% more. IF tires decrease soil compaction, which vastly improves short- and long-term crop yield. They accomplish this by incorporating sidewall technology that allows the farmer to run his equipment at up to 40% lower air pressure while preserving the tire’s load carrying capacity.

But that technology may come at a cost: All of that sidewall movement and flexion has resulted in reports of sidewall stress, cracking and even lug tearing, among other reported problems.

A Different Approach

In the mid-1990s, Titan International chairman and and CEO Morry Taylor was on a mission. You see, he recognized an opportunity for his global tire and wheel manufacturing company to address a need that few recognized. (Full Disclosure: while my employer does distribute ag tires, we have no relationship with Titan or any of its subsidiaries.)

The capable minds over at Titan introduced what they called “low sidewall” (LSW) technology. LSW technol- ogy addresses the concern of soil compaction by significantly reducing sidewall flexion and improving tread face integrity, which allows farmers to gain tread width to improve field traction and flotation.

Instead of the uber-flexible sidewalls found in IF tires, LSW tires are built exactly how you may picture them – with ultra-low sidewalls, like a UHP radial for your Corvette. The astounding part about this technology that it performs contrary to how you may envision a tire with a stiff sidewall performing.

According to Titan’s dedicated LSW website – lswadvantage.com – the vision for the technology came from the passenger and light truck segment, specifically from Euro-inspired HP and UHP tires that managed to combine high performance handling and traction with ride comfort.

What does this LSW technology actually do? There are essentially four primary benefits to LSW tires vs. traditional ag tires in the field:

1) Improved ride comfort

2) Less loping

3) Reduced power hop

4) Improved handling

Improved ride comfort allows the operator to remain in the fields for longer periods of time, which improves efficiency and reduces fatigue. Don’t think that’s important? Try talking to the guy at the helm of a harvester for 12-plus hours a day. He’ll be happy to set you straight.

Less loping and reduced power hop results in a couple of benefits that are particularly interesting. Much like the tire industry, there is quite a bit of consolidation in the fields as well. In other words, the big farms are getting bigger and the small are getting smaller. That’s becoming more noticeable because it’s not just the equipment, but most notably the tires that must perform and move better through the fields.

Not only that, but as farmers acquire new property, more of that equipment is forced to travel on paved roadways in excess of 50 or 60 miles at a time, at speeds of 25 mph or more. Harvesters on asphalt are no Cadillacs.

Field Results

So why don’t the farmers just break down the equipment, load it onto a low-boy trailer and haul it the 50-60 miles to the next job? In most cases, that simply doesn’t make financial sense. As the popular phrase goes, downtime is expensive. And as Titan says, “Where downtime is the enemy, LSW is the solution.”

In fact, Titan provides a number of real-life case studies on its dedicated LSW website that compare LSW tires to traditional tires. One particular 2013 field analysis done in Perry, Iowa, pitted a pair of Deere 8360s against one another. Both pieces of equipment were set up identically with the fronts inflated to 10 psi and the rears to 8 psi. Then, the auto drive was set and the two pieces of equipment were turned loose in the fields.

The Deere mounted with LSW tires handily outperformed the rig with traditional tires and resulted in just 2.9% slip during that test.

Another evaluation compared the LSW technology against tracks. In this case, although the LSW tires experienced 4%-12% slippage compared to the tracks’ 2%-5%, the LSW tires managed to surpass the tracks in overall fuel consumption at about 23 gallons per hour (GPH) vs. the tracks’ fuel consumption of around 30 GPH.

To the average reader, that may not seem significant, but multiplied over thousands of acres, this LSW stuff starts to make more and more sense.

The technology certainly isn’t perfect and despite Taylor and Titan’s best efforts, OEMs have been slow to acknowledge and adopt the tires and wheels. They feel that because LSW tires and wheels are limited to a single manufacturer, distribution and product availability in the replacement market become a factor.

And that is a problem.

“I’m sure there’s added-value to the products due to the configuration, but I don’t believe there is enough added-value to justify the cost of the tire and wheel combination and convince the average farmer to go this route,” says Sam Stephenson, TBA manager for Tennessee Farmers Co-op in La Vergne, Tenn. “I do believe this will have to hit the OEMs before Titan is going to make any real headway in the market.”

Teslas and Tractors

Perhaps Taylor ought to consider taking a looking across industries for a potential solution. Earlier this year, Elon Musk, the South African-born CEO of Tesla, publicly stated that he would not pursue patent infringement lawsuits against any global vehicle maker choosing to develop new electric vehicles using Tesla’s patents in good faith.

That’s a bold move and a big deal because it defies traditional thinking that companies should fight to protect their intellectual property.

You see, Musk and Taylor have similar problems: Slow adoption of new and innovative technology slows down their growth and opportunity.

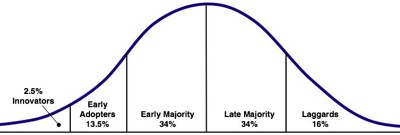

I’ll defer to the law of diffusion of innovation, which tells a very interesting story that’s repeated itself time and again across multiple industries. In order to intrigue and capture the early and late majorities, you must first capture the innovators and early adopters, who tend to make up a very small portion of the total population. About 2.5% and 13.5%, respectively (see chart on page 66).

Tesla accomplished this with its original $109,000 Lotus-based Roadster, and later with its $96,000 Model S. Future plans expand into the SUV segment with the Model X and later a $35,000 Model III sometime in 2017 or 2018.

By making the patents behind its LSW technology available to other major players in the ag tire sector, or perhaps pursuing a joint R&D venture, Titan stands a much better chance at capturing the attention and intrigue of the likes of Deere, Case IH and New Holland, just to name a few.

That may also prove easier said than done.

Where Everyone is Headed

I recently had the opportunity to speak with Tom Rodgers, director of sales and marketing for Bridgestone Americas’ ag tire unit; James Crouch, farm segment marketing manager for Michelin North America; and Bruce Besancon, vice president of marketing for Alliance Tire Americas.

When asked about their strategies for decreasing soil compaction, both Rodgers and Crouch were quite clear that Bridgestone’s and Michelin’s flotation strategies revolve largely around IF and VF technology. In other words, LSW isn’t on the table for either maker at this point.

“The industry is clearly moving toward IF and VF technology,” said Besancon. “This ultimately benefits the end user because it doesn’t lock them into a particular tire technology.”

Alliance’s strategy largely follows a three-pronged approach: advancements in tread, architecture and materials must be equally durable and robust. A pseudo-mechanical engineer and marketing professional at heart, Besancon has held job assignments on six different continents and has worked globally with major mining and construction companies for the past 25 years. In other words, there are few in the country who are as qualified to speak on the subject.

“Architecture becomes much more important with IF and VF technology, and we’re focused on making major advances in tread, materials and, of course, architecture,” said Besancon.

Time will tell whether or not LSW technology captures the attention of the majority or if this 15-plus year passion project will dissolve and fade away into tire industry oblivion. One thing is for certain: the world needs more companies like Titan to continue making critical strides towards new and innovative technology. Our future quite literally depends on it.

I’ll leave you with a quote from a man I think you’re likely to recognize. In the words of the late, great Steve Jobs, the people who are crazy enough to think they can change the world are the ones who do.

“Capital isn’t so important in business. Experience isn’t so important. You can get both these things. What’s important are ideas. If you have ideas, you have the main asset you need, and there isn’t any limit to what you can do.”

– Harvey Firestone