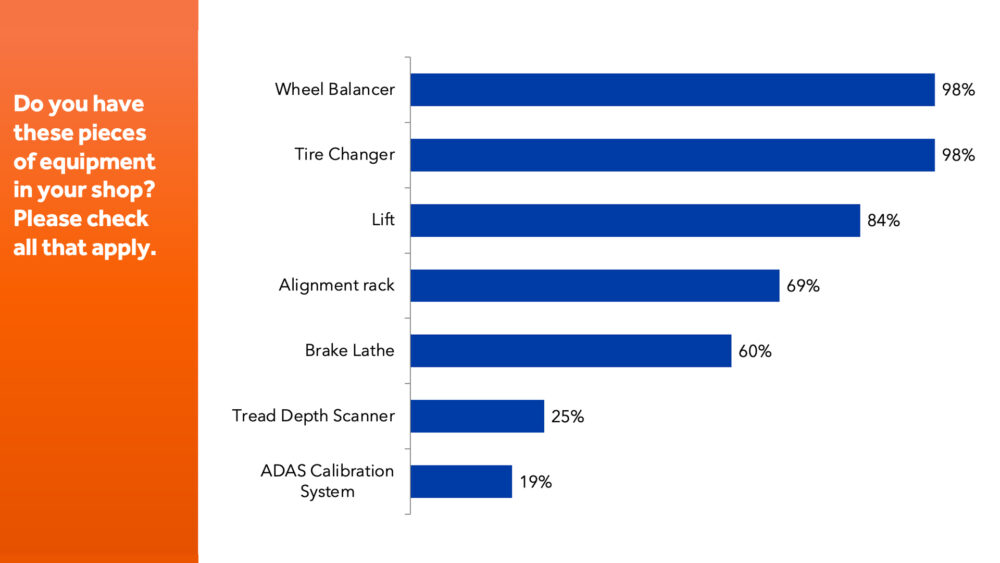

In this week’s show, we’re talking about shop equipment – more specifically, we’re talking about determining the right time to replace your shop equipment. Here’s the thing about tire shops: You don’t really need all that much equipment to get the job done. Sure, if you want to, you can go all out and deck your bays out with the latest ADAS calibration systems and giant automated robotic tire changers… but really, all you actually need is a tire changer and maybe a wheel balancer to consider yourself a bona fide tire business.

Our latest survey shows this, with nearly every dealer who took the survey telling us they have at least a wheel balancer and tire changer in their shop. Of course, most of you do more than sell and install tires, so those shops also come stocked with a lift and alignment rack.

Brake lathes are rather hit or miss with 60% of dealers reporting they own one, and, as expected, not many shops have invested in tread depth scanners or ADAS calibration systems. This makes sense when you consider the upfront investment and space requirements these two equipment choices require, though that’s not to say the dealers who own them aren’t getting great use out of them.

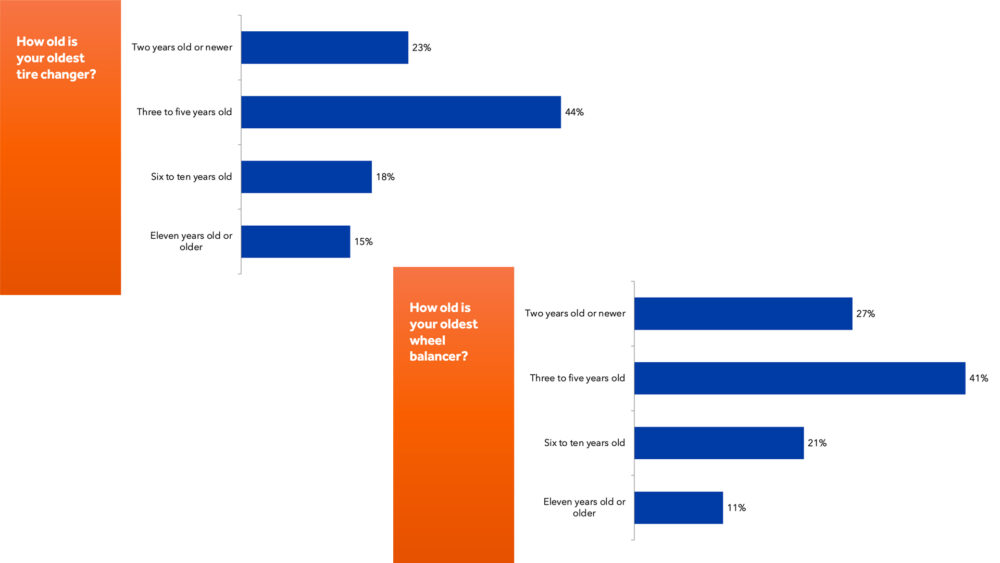

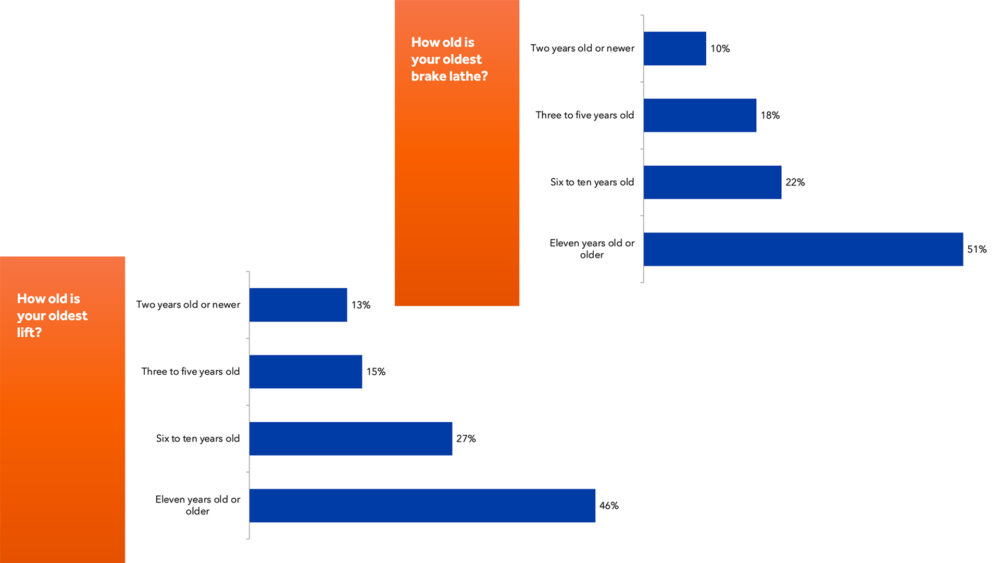

Here’s something I found especially interesting: Look at the results when we asked tire dealers how old their oldest equipment is. The graphs depicting the age of wheel balancers and tire changers, which nearly all tire dealers say they own, look pretty close, with most dealers telling us this equipment in their shop is between 3-5 years old, and very few are holding on to this equipment once they hit double-digits in age.

Now, compare these results to tire dealers’ oldest brake lathes and lifts. Here, we see that right around half of dealers in both cases are holding on to this equipment for 11 years or longer. Can you guess why there’s such a disparity between tire changers and balancers on the one hand and brake lathes and lifts on the other?

Well, here’s a hunch. In most cases, I don’t think it comes down to a matter of more solid production or better or worse quality assembly. I think it’s more so about technology. Brake lathe and lift technology just doesn’t have to evolve at the same pace as technology does in tire changers and wheel balancers.

That’s not to say there isn’t a good reason to replace lathes and lifts earlier than 11 years – new EVs on the road, for instance, might require you to buy new lifts sooner than you expected to handle the additional load if you begin servicing these vehicles – but in general, tire dealers can get away with holding on to this equipment longer. Now consider changes in vehicle types and trends as it relates to rim sizes, new tire compositions, low profile tires, the emergence of TPMS, even fuel economy regulations on the commercial tire side… all of this could affect whether or not your tire equipment is equipped to do the job you need it to do.

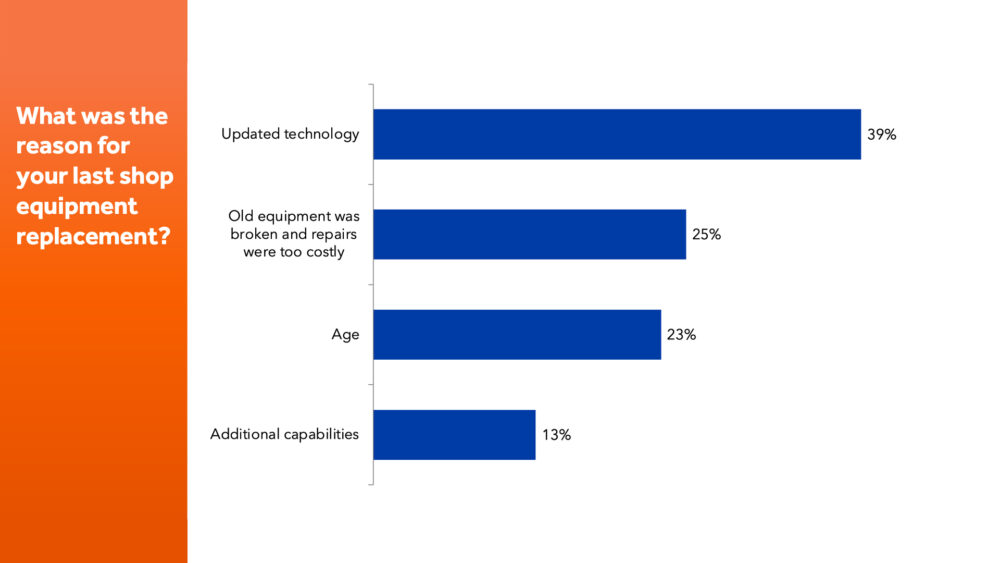

And, actually, when we asked tire dealers what the No. 1 reason was for their last shop equipment replacement, updated technology was the No. 1 answer, followed by repairs being too costly, and age. It just goes to show how much tire dealers need to be keeping up with tire technology to keep their businesses moving. At first thought, it’s easy to say that there isn’t much to tires – I mean, they’re all black and round, right? But this data tells us that if you aren’t staying on your toes and pivoting with the trends in this industry… you’re going to get left behind.

For more business intelligence data to help boost tire dealer profitability, be sure to watch out for our next episode of Rollin’ with the Numbers.