The days of driving a vehicle around the block to check for problems are over. With today’s sophisticated technology, test drives have become so much more.

Verification of work done correctly is an interesting statement. Is it the ability of vehicles to warn a driver or even react to an impending event such as leaving your lane or preventing a crash? This may not be verification of work done correctly, but verification of a system working properly.

Verification

According to Webster’s Dictionary, verify means “to establish the truth, accuracy or reality of.” In essence, we verify what we do. And we are not the only industry that performs a verification process.

When people leave a vehicle in your shop, whether they know it or not, they are trusting you to do the job right. They are betting their lives and the lives of their families on your work. Yes, it seems melodramatic, but it is true.

Consider the person who is involved in a crash. Most people will believe it’s not their fault: “My car wasn’t driving right;” or “It was pulling or braking when it should not have;” or “It did not warn me or do what it said it was supposed to.” You can say all you want about how the driver has the ultimate responsibility, but without verifying and documenting that the car was working correctly, good luck convincing a jury.

Nobody wants to intentionally do a job wrong. Those who do are a different subject for a different article. When a job or procedure is done wrong, the reason can be attributed to a variety of things:

- Ignorance

- Leadership

- Apathy

- Cost

- Improper training/tools for the job

No matter what the reason, a verification process can help shops find deficiencies and correct issues before those issues impact a customer. I find verification and documentation to be a best practice in protecting against liability.

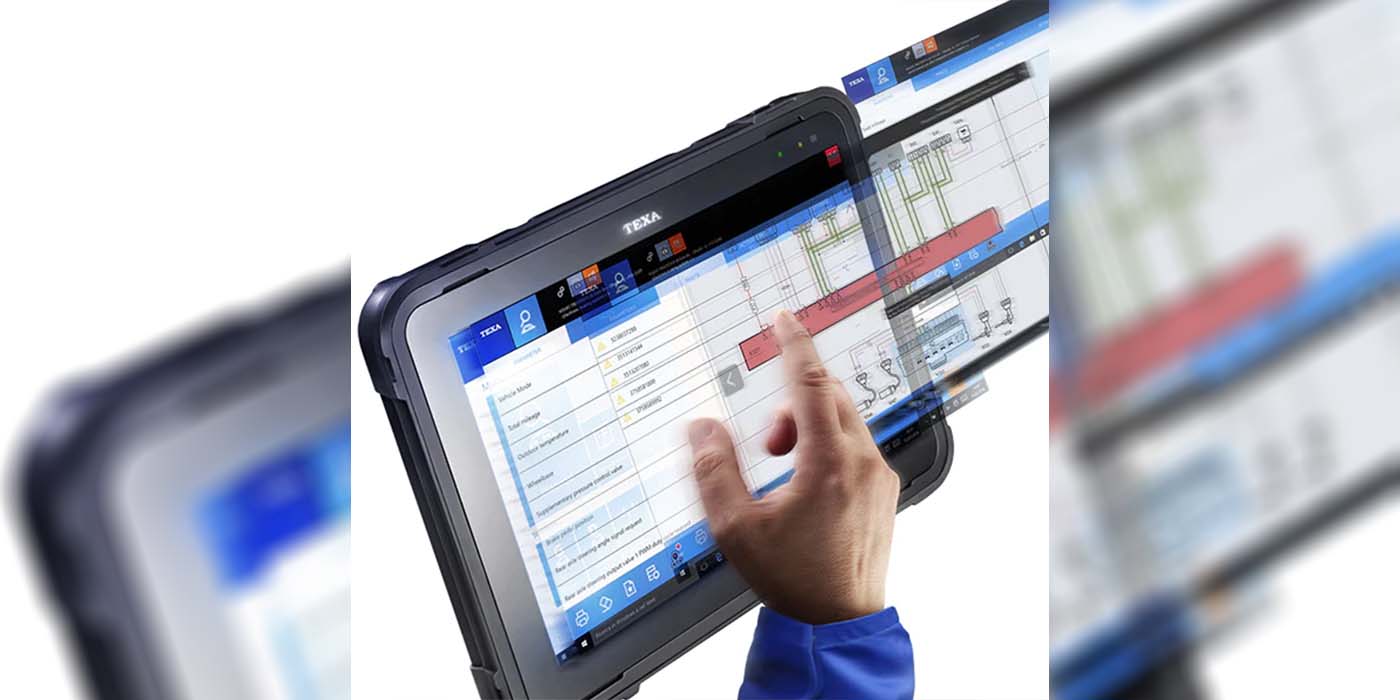

With today’s safety systems taking control of a vehicle, verifying that they’re operating correctly will require different procedures than most repair shops are used to performing.

Test Drives: The Most Overlooked Verification

With today’s safety systems taking control of a vehicle, verifying that they’re operating correctly will require different procedures than most repair shops are used to performing.

Static recalibrations using targets for cameras and/or radar units are just one factor. These procedures are used to verify that the sensors or equipment are aimed correctly. Verifying their operation requires a test drive by someone who knows how the system operates. The days when a light on the dash or lack of a light was a determining factor that everything was working are gone. So, too, are the days of driving a vehicle around the block to check for problems.

Shops today need to research how the system works and what items the vehicle manufacturer requires them to test. These items include:

- Clearing codes

- How far a vehicle must be driven in time or miles

- What type of roadway and signage are necessary?

- How fast a test must be done

- Environmental conditions like snow and rain

- Stopping and starting requirements

- Vehicles on the roadway

- Alignment

- Aftermarket accessories

- Post-repair scan after a test drive

I’m probably missing some items, but you get the point. A test drive is far more complex today than in year’s past. There are many factors that have to be met when test driving for recalibration, including clearly marked roads, signage and weather conditions.

You need someone who knows what the codes say, and who has the experience necessary to verify that all systems operate correctly.

The time it will take an experienced person to be able to know what and how it all works is important to all. The idea that it may take two scans at the end of a repair is beyond some folks’ comprehension. But you will comprehend that much better when a customer brings their vehicle back saying it does not drive right.

Many people think all of this is overkill and has been overhyped. It is not. As vehicles become more involved in the reaction time to driving hazards, the proper operation of all safety systems becomes more important. You cannot take for granted how much liability is involved. We are not just conscientious about upset vehicle owners.

Not Just a Test Drive

Many shops, like most people, are resistant to change. There is also a resistance to paying for new, necessary operations. Many downplay the seriousness of this issue and want to tell you it’s just plugging in a scan tool; anybody can do it. We’ve heard this all before. It does not take long to realize that it takes a trained person to do the procedure.

Yes, to start, it may be simply plugging into a vehicle’s OBD port. How many times has a code popped up? How many times do initialization procedures or recalibration procedures not get looked up at the beginning of the repair process? How many people would recognize that the vehicle blind spot did not pick up the small car that just passed by? It’s not just a simple test drive to be performed by an inexperienced employee. It’s not only plugging in a scan tool. If the car was never damaged, it’s easy to say that. When the car has been damaged, this is a whole different situation. You need someone who knows what the codes say or what procedures need to be done, and who has the experience necessary to verify that all systems operate correctly.

We have organizations (AAA, National Safety Council, etc.) that are still trying to establish consistent names for all these new parts and systems. Many people think if they don’t unplug the sensor or if the MIL light is off, they’re good to go. You see and hear this at meetings or in conversations with peers. You wonder, what are they thinking? That becomes the crux of our plight.

Training on what these electronic systems do and how they do it, as well as training on how to find information on what a shop is supposed to do, takes time and money. And, that has to be included at the beginning of the repair process.

Things are changing. You need to be sure you know what you’re doing. It’s not just a test drive.

Mitch Becker has been a collision industry trainer for 30 years and is a contributor to Tire Review’s sister publication BodyShop Business.