In Part I of this article, which ran in the January issue of Tire Review, OEM tire and manufacturing plant RFV (Radial Force Variation) was discussed.

In Part II of this article, we’re going to move to tire/wheel RFV in terms of tire vibration problem-solving in the tire shop.

When balanced, the rounder the assembly, the lower the RFV and the better the ride quality.

Measuring RFV must rely on the correct process with a wheel balancer or else measurements cannot be relied upon for a correct diagnosis and repair. Most wheel balancer operators are not trained properly to use the equipment, which leads to incorrect diagnoses and inferior balancing services being performed. Used tire and wheel assemblies must always be road tested (exercised) in order to eliminate temporary flat-spotting measurements. New tires stored improperly may also have temporary flat spots that must be eliminated before the correct diagnosis and repair can be achieved.

If you own an RFV wheel balancer of any brand, make sure your techs know how to: first, quickly find the RFV; and second, reduce the RFV. Most techs don’t use the RFV capability because nobody has taken the time to show them how simple and fast it is to do and how to do it right the first time.

There are few basics to remember when it comes to RFV balancing:

- The most important measurement by far is finding the clock position of the RFV high spot. The location of the high point is in the belt plies splice area of the tread belts. The location of the “taller” or “stiffer spring” is always in the same area regardless of the measurement method being used for contact or non-contact measurements. RFV, eccentricity and radial runout measurements are all the same “high spot” in shop balancers.

- The actual unit of measurement (in., mm., lbs, Kg., N.) is not so important. The goal is to find the high spot, make sure it’s not too high and adjust it to make it lower, if necessary, to provide the best balance.

Tires and rims are of a much higher quality today and have much less eccentricity compared to 15 to 20 years ago. However, virtually all car manufacturers still measure RFV and match-mount tires on the assembly lines because it’s virtually impossible to build a perfectly round tire, and then mount it perfectly round on a tightly machined rim bead seat that pops like a gunshot when inflated. They continue to do this because it makes a big enough difference in improving ride quality. If they follow these best practices, so should you.

Sources of High RFV

High RFV (eccentricity) can come from the following items:

1. Incorrect Centering Adapters Used on the Wheel Balancer

If the wheel is not centered on the wheel balancer properly, stop right here and don’t waste your time or your customer’s money to try to balance.

2. Improper Tire Mounting Process

To ensure the best tire uniformity and ride quality, Michelin’s Tire Fitment Guide states that once the tire has first been properly lubricated, sealed and seated (with the valve core removed), it should then be deflated so that the beads relax. Then, the tire should be re-inflated and brought back up to placard inflation pressure to allow the beads to move back into their correct position on the rim bead seats. This is critical today if you want uniform tires and wheels.

3. Bent Rim

Inspect and replace as needed. Rim bead seat area corrosion can also create high RFV measurements along with the associated air leaks due to bead seat corrosion.

4. Improper Vehicle Centering

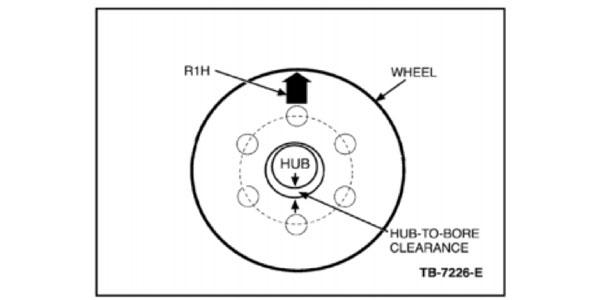

Before removing the assembly from the balancer, perform an on-car vehicle hub RFV reduction. First, rotate the high point to 12 o’clock (TDC) using the prompts on the balancer screen. Then, mark the high point/stiff spot on the inside of the rim edge and tire with a tire crayon. Next, place the assembly on the vehicle hub with the index mark at TDC. Finally, install and torque the lug nuts/lug bolts per factory specification.

Below are some tips to remember during the RFV balancing process:

1. Rotate the Tire 180 Degrees to the Rim.

If the assembly has a high RFV (eccentricity) number, always use a simple mark for the high spot and 180° turn of the tire on the rim (with some lube and process above) to attempt to reduce RFV. If the RFV drops significantly, the tire and rim may not have been sealed and seated properly when mounted or not optimized during the assembly process. This process is speedy and does the trick over 95% of the time without the tire or the rim needing to be replaced.

2. Flat Spotting of the Tire (temporary or permanent)

Never measure the RFV of a tire and wheel that has not been driven. It needs to be driven so that the tire has been exercised.

Consider this: By using RFV measurement reduction and on-car cancellation of the eccentricity, a tire and wheel with some RFV can actually ride better than if it had none. As an example, if the assembly has RFV of 0.015-in. R1H (25 pounds Radial Force Variation) when placed on the vehicle, the hub clearance could subtract and cancel almost the same amount creating a “net zero” assembly. Just mark the high point and place it on the car at 12 o’clock… on everything.

As you can see, the ability of a wheel balancer to also measure RFV is critical for a number of reasons.

- Vehicle and tire manufacturers have been using this equipment for years to be sure their tires are uniform and don’t create vibration.

- RFV is unrelated to balance.

- RFV is not something that can be seen with the eye in a busy tire shop during wheel balancing.

- The ability to quickly measure RFV (out of round, eccentricity) and convert those measurements to harmonics is a powerful use of an RFV wheel balancer computer.

- Having a round and balanced tire is what makes it rotate smoothly on the road.

Some RFV acronyms found in the tire service business are defined as follows:

Road Force Variation: A registered trademark of Hunter Engineering Co. that estimates Radial Force Variation, SAE Practice J332. The machine uses a roller, angle measuring sensors and algorithms to calculate radial runout and multiplies the measurements by a tire stiffness measurement (Example: 0.010in. x 1000 psi ~ 15 pounds Road Force). Runout peak-to-peak measurement is converted to a harmonic display of RFV. Steps need to be done properly in the process to ensure the estimate of Radial Force Variation correlates.

Runout Force Vectoring: A registered trademark of Snap-On Equipment Co. that estimates Radial Force Variation, SAE Practice J332, by measuring runout on a wheel balancer with Sheet of Light lasers and Michelin-developed algorithms. Runout measurements are multiplied by tire stiffness calculations based on pre-programmed tire pressure, tire size and rim dimension measurements. Steps need to be done properly in the process to ensure the estimate of Radial Force Variation correlates.

Radial Force Vector (RFV) Wheel Balancer:: A general term adopted for any shop wheel balancer that also measures radial runout of the tire along with standard balancing capabilities.

Check out the rest of the February digital edition of Tire Review here.