There are more than 3.6 million 2009-’14 Ford F-Series trucks on the road today, and the majority of them are the F150 model. The 12th generation of the truck, and specifically its brake system, has had very few problems since most of the brake system was carried over from the previous platform.

Front Brake Pads

For the 2010 model year, Ford made some changes to the brake caliper and pads; namely, the inner and outer pads are different. If the pads are mixed up, the caliper can hit the spokes on the wheel and cause damage. To install them correctly, note that the inner pad’s backing plate has two ears on the top of the pad that match up to the brake caliper pistons. The outer pad has a chamfer on the top.

The pads have the same ears that rest in the lands of the caliper bracket. It is possible to install the caliper and the guide pins over the mixed-up pads. It is also possible to get two inboard pads on one side and two outboard pads on the other side.

If the pads are installed in the wrong positions, the caliper could come in contact with the inside of the wheel when the brakes are applied. The brake caliper bracket has a torque spec of 184 ft. lbs. The caliper guide bolts have a torque spec of 27 ft. lbs.

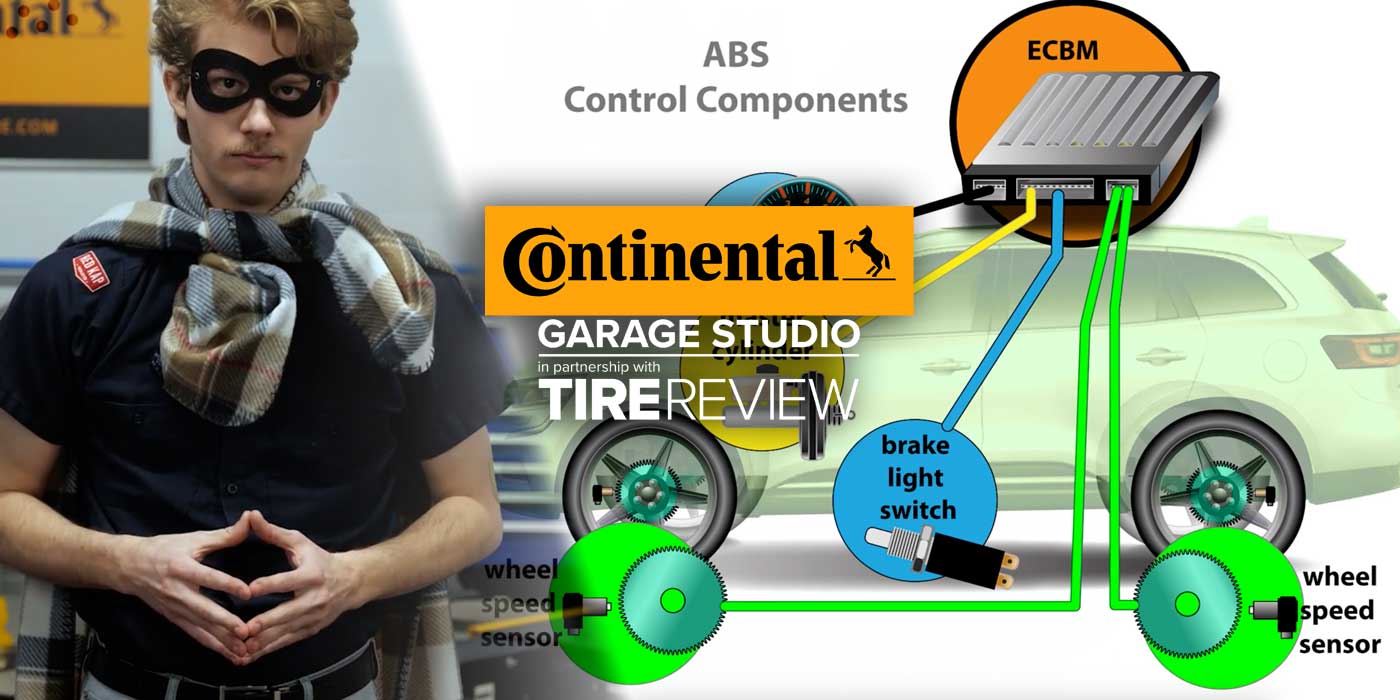

Rear Brakes

When you remove the rear rotors, inspect the ABS tone ring and the condition of the parking brake hardware. Check the actuators that are attached to the parking brake cables, as they are known for seizing. Be sure to also check for contamination from worn axle seals.

If you see uneven inboard pad wear, it could be a sign that dirt or a rock may have lodged between the caliper and mounting plate. The caliper guide pins have a torque specification of 22 ft. lbs.

The upper guide pin has a dampener designed to minimize noise and vibration. This round piece made of rubber and metal is tuned to the natural frequency of the brakes. If it is damaged, aftermarket replacements are available.

Parking Brake

The parking brake uses a foot-operated parking brake control that is self-adjusting. To release the tension, pull down on the intermediate cable at the cable-to-cable union on the frame until the parking brake control sector rotates to its stop and a 4 mm retainer pin can be inserted. Disconnect the cable at the union.

To adjust the parking brake shoes:

- Measure the diameter of the inside of the drum of the rear rotor.

- Adjust the shoes so they are 0.71 mm (0.027 in.) less than the inside diameter of the rear rotor.

- Connect the cables at the union and remove the pin from the parking brake foot pedal assembly.