The team at Bendix Commercial Vehicle Systems (Bendix) offers suggestions on getting ready for Brake Safety Week, happening this week (Aug. 21-27). Brake Safety Week is the annual weeklong event run by the Commercial Vehicle Safety Alliance (CVSA) that examines vehicles across the United States, Canada, and Mexico.

Bendix says Brake Safety Week is part of CVSA’s Operation Airbrake initiative, an outreach and enforcement campaign that aims to reduce the number of highway crashes caused by faulty brake systems on commercial motor vehicles. The event involves local, state, provincial, territorial, and federal motor carrier safety officials in the United States, Canada, and Mexico inspecting large trucks and buses, focusing on brake system violations.

Brake Safety Week roadside inspectors conduct North American Standard Inspections, which cover a range of driver qualifications, documentation, and vehicle equipment conditions. They’ll be checking for:

- Missing, non-functioning, loose, contaminated or cracked parts;

- Holes caused by rust and through rubbing or friction;

- Broken springs in the spring brake housing section of the parking brake;

- Air leaks around brake components and lines;

- Air pressure in the target range of 90-100 psi;

- Slack adjusters are not at the same length;

- Mismatched air chamber sizes across axles;

- Warning device functionality (such as antilock braking system indicator lights).

“Pre, post-trip, and regular inspections can go a long way toward catching some obvious violations, including loose hoses or damaged components like air chambers or pushrods,” said Mark Holley, Bendix director of marketing and customer solutions, Wheel-End. He recommends the following:

Every Day:

- Check for damaged or loose-hanging air chambers, pushrods, or slack adjusters.

- Make sure slack adjusters on each axle are extended out to the same angle. Different angles can indicate an out-of-adjustment brake or a broken spring brake power spring.

- Examine tubing and hose condition, positioning, and connections.

Every Week:

- Perform a 90- to 100-psi brake application with the wheels chocked and the parking brakes released, and listen for leaks.

- Check air disc brake rotors for cracks.

- Inspect drum brake linings for wear and cracks.

Every Month:

- Check for moisture in the air system to prevent contamination that leads to component deterioration and system leaks.

- Regarding brake hose and tubing chafing, the focus of Brake Safety Week this year, Bendix recommends watching for two typical causes. First is improper routing and clipping, which can cause hoses to rub together while the vehicle operates. Preventive measures include periodic inspections to ensure tie straps, clips, and any brackets are not damaged or broken. The second typical cause is improper hose length – an overly long replacement hose is susceptible to chafing. Bendix says damaged hoses should be replaced.

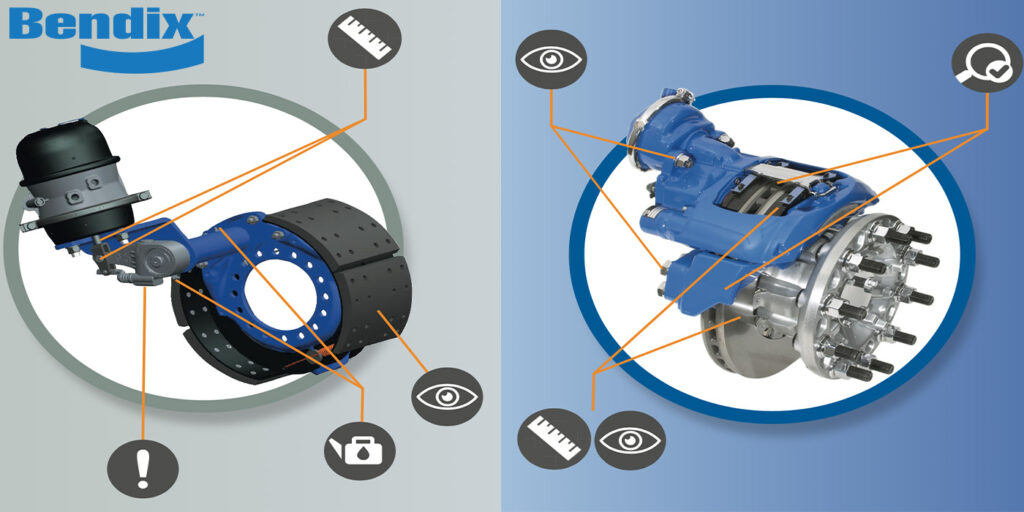

Where Brake Safety Week is concerned, air disc brakes and drum brakes have a few differing maintenance needs. Bendix says measuring a drum brake’s chamber stroke is a matter of checking the distance from the air chamber to the clevis pin with the brakes released, and then again after a fully charged brake application. The difference between these is the brake stroke, and its maximum length depends upon the brake chamber type and size.

If you notice it’s time for new brake friction, Bendix says to make sure to keep things up to spec. Not all friction marketed as “acceptable” under currently reduced stopping distance (RSD) regulations will perform to that standard. Whether you’re replacing air disc brake pads or drum brake shoes, Bendix suggests selecting components that will ensure the original equipment manufacturer (OEM) requirements are met, so that the vehicle remains compliant.

When it comes to remanufactured drum brake shoes, Bendix says to ask your supplier whether they have been coined back to their OEM-engineered shape, and not simply relined with new friction. Shoes become misshapen under the stress of regular use, and relining one of these without returning it to its original geometry can impact stopping power and friction life.