When was the last time you checked your lift’s cables? If you answered “today,” good for you! Cables are one of the things you should check before using your lift every day. In this article, we’ll explore how to maintain your lift cables or “wire ropes,” how to look for damage and when to replace a cable.

Keep Them Lubricated

The better you take care of your cables, the longer they’ll last. One of the best things you can do is keep your cables lubricated with 85W90 gear oil or ALMASOL Wire Rope Lubricant. These lubricants get deep into the fibers to protect against wear and damage. Lubricate your cables every three months.

Look for Damage

Start by relaxing the rope to a stationary position and moving the pick-up points off the sheaves. Clean the surface of the rope with a cloth or wire brush so you can see any breaks.

Flex the cable to expose any broken wires hidden in the valleys between the strands. One way to check for crown breaks is to run a cloth along the rope to check for snags.

Use an awl to probe between wires and strands. Lift any wires that appear loose. Evidence of internal broken wires may require a more extensive rope examination.

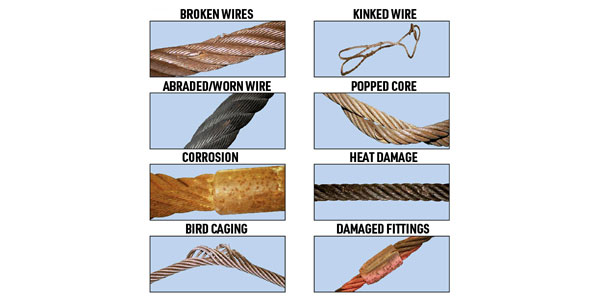

Other damage to look for includes abrasive wear, mechanical damage, rotational damage, heat damage and bending fatigue.

Replacement Time

All lifting cables should be replaced every three to five years or when damage is visible. Does that mean every cable that looks “less than brand new” after a couple years of heavy use should be replaced? Not necessarily.

A little wear is to be expected over time. A good rule of thumb is: If, over the course of a single day, you see six random wires sticking out over the length of a single cable (when examining all strands), the entire cable should be replaced. Additionally, if you see three broken wires in just a single strand over the course of a day, you also need to replace the entire cable.

Also, replace cables that have worn down by 10% of their original size. For example, if the cable was originally 0.5 inches in diameter, replace it once it reaches 0.45 inches. While the difference may seem small, a 14,000-pound- rated cable that loses 10% tensile strength will subsequently be rated at just 12,600 pounds. This is a significant reduction in capability when it comes to lifting heavy-duty vehicles.

Cables should also be replaced if they are pitted by corrosion or if there is evidence of kinking, crushing, cutting, bird-caging, a popped core or heat damage.

If you find damaged cables meeting any of these criteria, replace them immediately. Do not use the lift until the damaged cables have been replaced.

Content provided by Bendpak.