Although belts and hoses are still classified as expendable parts, their durability has improved to the point that many dealers and technicians are now neglecting to perform routine belt and hose inspections.

From a historical perspective, belts and hoses have moved from a recommended replacement interval to an inspection interval. This means that, unless otherwise required, there generally is no recommended replacement interval for belts and hoses. The consequence of moving from replacements to inspections is that many shops are missing potential profits in belt and hose replacements.

Just recently, I had a 2001 Asian import come in for a check engine light issue that illustrates what is happening in the belt and hose markets. Because the import wasn’t a popular brand in my area, many shops had turned down the diagnostics. So, after working with a vacuum schematic, I found the cause for the diagnostic trouble code to be a clogged vacuum line.

The inspection also revealed that the owner was ready to leave on a long trip with a badly cracked belt. The vehicle had just been “serviced” and, in the owner’s mind, was ready for his long trip.

That wasn’t the case, however, because the belt was ready to shred its way off the pulleys within a few hundred miles of high-speed driving.

Unfortunately, in their haste to sell wiper blades and fluid flushes, many quick-lube mechanics overlook expendable items like belts and hoses. Although replacing the belt wasn’t difficult for a well-tooled tech, it would have been difficult for any repair facility that didn’t have the metric wrenches needed to fit under a tight-fitting intake manifold and power steering bracket.

The A/C compressor and power steering belt also had to be removed before the alternator drive belt could be accessed. Years of corrosion made removing the A/C compressor belt more challenging than it should have been, and an even greater array of tools was required to budge the tensioning pulley from its corroded mounting.

Perhaps this example explains why many quick-service facilities give hose and belt inspection a relatively low priority on their service menus.

Belt Inspections

Belt inspections aren’t difficult. The first clue to a bad belt, for example, is a belt squeal heard during engine start-up. The second clue might be a belt squeal heard during parking maneuvers or during an alternator load test.

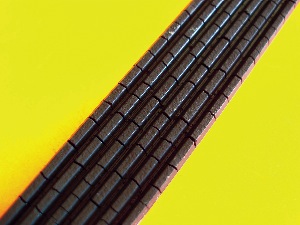

The last clue is the fraying and cracking associated with a worn-out belt (See Figure 1). A frayed belt might indicate a pulley alignment problem, so it’s important to include some diagnostic time for inspecting and possibly correcting pulley alignment.

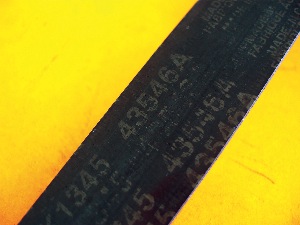

Many manufacturers promote replacement level standards that might include the number of cracks per inch present on the inside of the belt. In addition to whatever standard might be published, I inspect the outside of the belt for signs of glazing or pulley slippage. If the original part numbers and markings are still visible, all is well with the belt and pulleys. On the other hand, if the belt is glazed or frayed, an idler or drive pulley bearing might be seizing up (See Figure 2).

In most cases, any belt running past 100,000 miles might be on borrowed time. Of course, many belts do last longer because of the variables that affect belt life, including the amount of torque transmitted by the belt, underhood heat, and exposure to oil and atmospheric ozone.

If, for example, the engine has separate accessory belts, the alternator belt will tend to crack and harden first because the alternator is continuously laboring to operate accessories and keep the battery charged. The air conditioning compressor drive belt might be the next to fail in warm climates. Here again, if the compressor is overcharged or is seizing up, belt life will suffer accordingly. Hydraulic power steering pump belts usually last the longest simply because they transmit maximum torque only under demand. Last, separate water pump belts transmit very little torque and are the most likely to incur the least wear.

Hose Inspections

Many years ago, the average water-cooled import had only four or five hoses, including the upper and lower radiator, heater inlet and return, and a water pump bypass hose. In most cases, the lower radiator hose had a wire reinforcement to keep the hold from collapsing at high engine speeds. Imports built during the past several decades may have a dozen or more small coolant hoses that perform diverse duties, like heating the throttle plate assembly or warming up thermostatic idle speed controls.

In general, the upper radiator hose on a conventional cooling system is the first to fail because it endures the hottest coolant temperatures. The lower radiator hose, on the other hand, may operate at lower temperatures and, thus, may last much longer. The same can be said of the auxiliary hoses, including the heater outlet and smaller-diameter intake manifold hoses that have minimal exposure to underhood heat.

Hose inspections are relatively simple if, when the engine is fully warmed up, we begin by looking for any unusual swelling or seepage around the connection point of the hose. If the sides of a hose feel mushy or spongy at full operating pressure and temperature, the hose should be replaced.

Similarly, if traces of coolant leakage are found around a hose connection, the hose has hardened and will likely leak if it’s reinstalled. If the cooling system is depressurized and the hose isn’t wire-reinforced, the radiator hoses can be evaluated by squeezing the sides together. Again, the rubber should feel firm to the touch. If the rubber feels soft or spongy, the hose is a candidate for recommended replacement. If the hose is so hard that it has lost its elasticity, it also becomes a candidate for replacement.

Belt and Hose Estimates

Economic times are tough, and it’s a demanding process to write an estimate for hose replacement that’s both profitable and competitive. Unlike other components, labor charges aren’t really an issue in many belt and hose replacements because they must be removed to gain access to other components like a water pump, timing belt or the engine itself. Because the labor is included in the replacement of another part in most labor guides, it simply doesn’t make economic sense to reinstall old, worn-out belts and hoses.

It’s also important to emphasize to the customer how much more expensive it will be to replace the hoses at a later date when the issue of hose accessibility must be fully addressed. On some imports, accessibility issues might account for hours of additional labor time, not to mention the difficulty of performing a reliable installation within the confines of a tight engine compartment.

The Security Issue

Lastly, remember that having good belts and hoses is a security issue for most drivers. While having good belts and hoses on the family’s “beater” car isn’t a primary issue for most, having those new belts and hoses under the hood of their primary transportation becomes not only a security issue, but also a dollars-and-cents issue if the vehicle is stranded on a long trip due to a belt or hose failure.