When balancing a wheel assembly, it’s important to prevent damage to the wheel during the process. Before balancing, remove the wheel weights if you haven’t already. When removing adhesive weights, only use a plastic wheel weight remover tool. Using metal tools can scratch the rim’s surface. Then, you’ll want to use a solvent to clean the wheel and remove any excess residue from the old weights as well as any brake dust.

Now let’s talk about proper mounting techniques. Wheels can be mounted to the balancer either via the center hub bore or via the lug holes with the use of a pin plate. It’s recommended to use a pin plate when servicing high-end wheels or ones that are easily damaged. Then, select the correct collet size for assembly. You’re looking for a snug fit of the collet into the hub bore, and once you’ve found the correct one, go ahead and thread it onto the spindle. It is critical that the collet supports the wheel on the structural taper for accurate balancing. Incorrect contact can allow the wheel to move while on the balancer, leading to false readings and an inaccurate balance.

Next, mount the tire onto the wheel balancer spindle. If working with a high-end or easily damaged wheel, use a wheel lift or ask another tech to help you with the assembly to prevent it from knocking into the spindle while mounting. Then, put on the hub nut and thread onto the spindle until tight. At this point, make sure the wheel is centered on the spindle. An easy way to check is to give it a spin and look for any wobbling that might mean it’s not centered or that it’s been installed with the wrong collet.

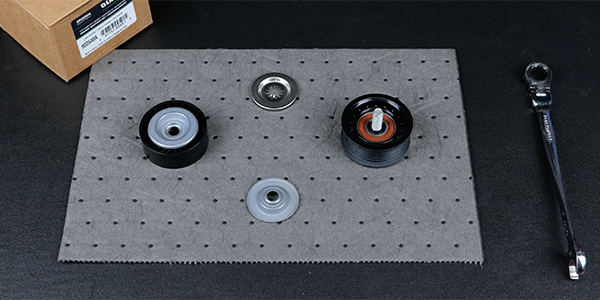

Once the balancer identifies where weight is needed, you’ll need to choose the right weight for the wheel. Here are some things to keep in mind.

First, you’ll want to decide what type of weight: clip-on or adhesive. Adhesive wheel weights stick onto the wheel and can be easily hid. If you choose clip-on weights for the assembly, you’re going to have to use a weight gauge to measure the style of the rim profile. Be careful with clip-on weights. When installed on aluminum rims, they can damage the protective coating and leave permanent marks when removed. If the proper weight style isn’t installed, there’s a good chance it will fall off and lead to a customer come back and possible damage to the rim. Some wheels feature rim flanges that are not intended for clip-on wheel weight application and are only added for decoration purposes. All rim flanges that are less than 3/16-in. deep should utilize adhesive wheel weights. If you use adhesive wheel weights, you should also check that the brake caliper clearance to the weight is a minimum of 1/8-in. to prevent damage and the weights being stripped off.

Next, you’ll want to choose between coated and un-coated wheel weights. Coated weights are for alloy wheels and uncoated weights are for steel wheels. If a coated or uncoated weight is used with the wrong wheel type, it can cause corrosion due to the dis-similar types of metal.

Once wheel weights are applied, do another spin to do a final check for imbalance. Once you see the machine zero out, there should be no vibrations felt by the customer and we can install it back on the car.

For more information about Blackburn OEM Wheel Solutions, visit blackburnwheelfinder.com.