EVs are coming. As manufacturers ramp up production of EVs across nearly all car and light-truck makes and models, selecting a high-quality brake pad is extremely important. The reason is twofold. Not only are EVs quieter than internal combustion engine (ICE) vehicles, making brake noise even more unwelcome, but EV braking system effectiveness can also be impacted by corrosion.

The common thought is that brake pad maintenance is reduced due to EV regenerative braking, a process that utilizes the electric motor to provide braking power while supplying batteries with energy during the braking process. However, corrosion is a common cause of brake pad failure. That threat remains as EVs drive through the same chemically laden roads in the winter. Corrosion happens when the paint that is used to protect many brake pads chips away and invites rust and ruins the brake pad.

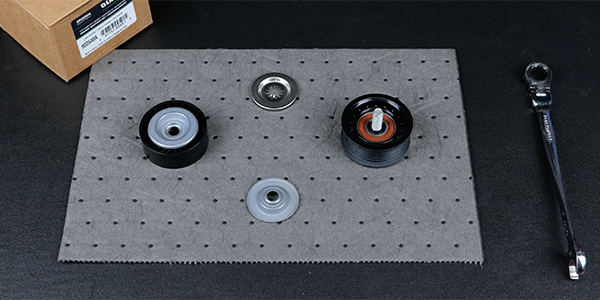

That brings us to our first EV brake pad selection tip: Choose a pad that features a galvanized backing plate. A galvanized baking plate, like the one found on NRS Galvanized Brake Pads, offers superior corrosion protection because the plate won’t rust or chip like painted backing plates.

You’ll also want to consider how the brake friction is attached to the pad. Many brake pads utilize a simple adhesive to attach the brake friction to the backing plate. Over time, that adhesive can fail and allow the brake friction to crumble off of the backing, especially if it’s corroded. For EVs, you’ll need a backing plate that is mechanically attached. Mechanical attachments bind the brake friction to the backing plate more securely. For example, NRS has a patented mechanical attachment process that utilizes In-situ Galvanized Hooks to embed the galvanized baking plate into the friction, creating the strongest brake friction to backing plate connection in the industry.

Both of these key features ensure that your electric truck retains braking power when you need it.

Speaking of using EV brakes, EVs are much quieter than ICE vehicles, making every noise even more noticeable. The squeal of a cheap brake pad can become an ear-splitting annoyance in an EV. The next brake pad selection tip is that you’ll want a pad that’s as quiet as it is durable.

Look for a brake pad that offers high-quality friction material as well as noise-reducing technology. You’ll want a brake pad that offers premium semi-metallic and copper-free materials, like the friction material utilized by NRS Galvanized Brake Pads. Not only do they contribute to brake noise reduction, but they also dissipate heat and cool efficiently, producing less brake dust, ensuring longer life and offering incredible, consistent stopping power.

Additionally, technology like the NRS Piston Cushion Insert, which is designed to help reduce the noise level by up to 90%, acts as a barrier to minimize heat transfer to brake fluids. This reduces brake noise and gives you the quietest brake pad in the world today.

EV braking systems are not a set-it-and-forget-it system. Regular brake pad inspection and maintenance are required to ensure safe operation. It’s not about how often you use your brake pads, it’s about how well your brake pads can fight corrosion.

For more information about EV brake pad selection and to order NRS Galvanized Brake Pads, visit: https://nrsbrakes.com/nrs-ev/