Wheel bearings are the connection between the suspension and brakes. When the bearings go bad, the typical wheel bearing job touches both of those critical systems.

The first step, and probably the most important, is inspecting the corner of the vehicle. Since the wheel bearing is part of the brakes and suspension, you need to look at the overall condition of all three systems. The goal is not to overwhelm the customer but to make an assessment of the condition of the brakes and suspension. It is also important to go for a test drive to confirm the customer’s complaint. Sometimes, tire noise is mistaken for bearing noise. The goal is to provide the customer with an overall assessment of the condition of the brakes and suspension. Relaying to them the overall condition and explaining how the components work together helps them understand the importance of replacing worn parts.

For the technician or service advisor, a bit of research may help identify specific reasons for early failures or new procedures. Service information is vital in this regard and for writing accurate estimates, saving the shop and customer time and money. But experience is also key in assessing the job to make sure 1.5 hours of labor do not turn into three. Labor times in a guide or from the OEM often are the best-case scenarios using vehicle-specific tools. Research technical service bulletins (TSBs) during your inspection while reviewing labor times. Assessing a job for the customer needs to be complete and accurate. Often an OEM will release a TSB regarding new procedures and tools for the wheel bearing replacement after a vehicle has been in the field.

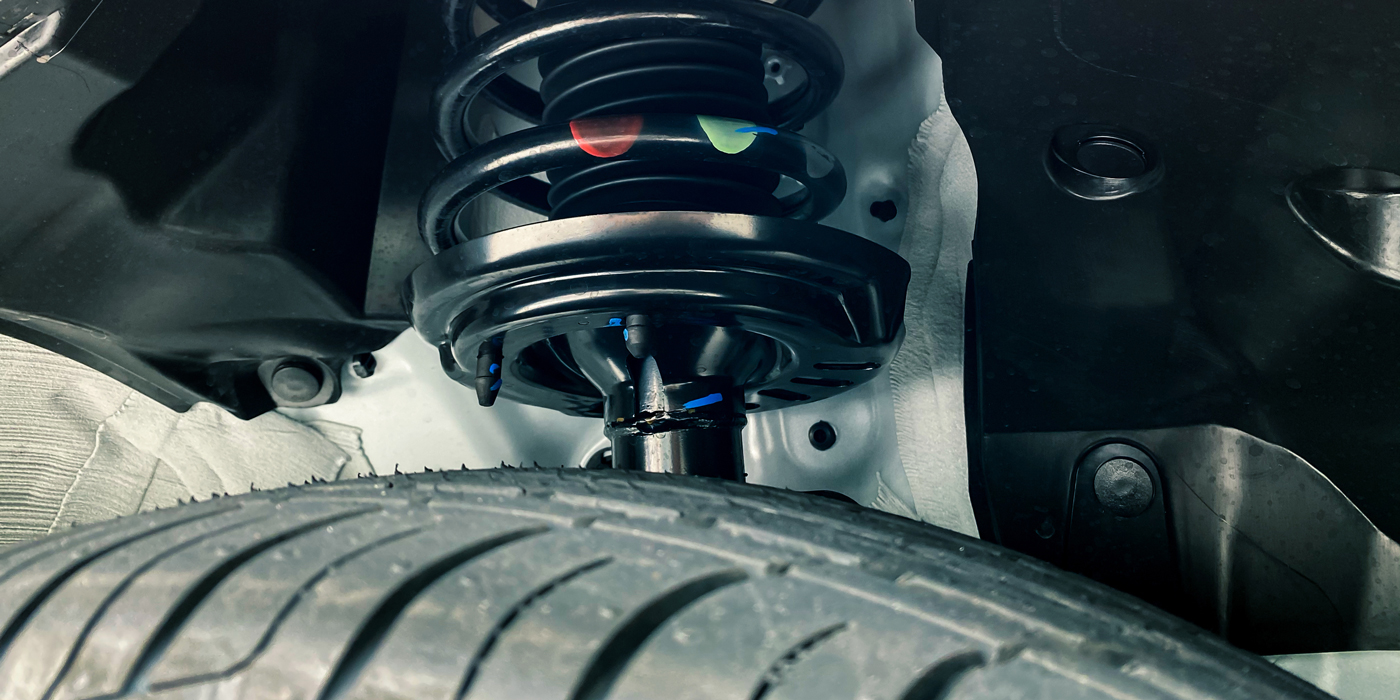

Explain any parts options that might be available including new cost-saving options such as wheel bearing kits, complete control arms with ball joints, loaded struts or new loaded knuckles.

Know The Load

On a typical passenger vehicle weighing around 3,400 pounds, each pair of front wheel bearings, as well as the rear wheel or axle bearings, support around 850 pounds depending on the weight distribution and driveline configuration. If it’s a 6,000-pound SUV, each bearing might carry about 1,500 pounds. This load is concentrated on the relatively small bearing surfaces. These loads do not even take into account the dynamic loads produced by cornering.

Since the wheel bearing is part of the brakes and suspension, you need to look at the overall condition of all three systems. Sometimes, tire noise is mistaken for bearing noise.

The loads that are put on the bearings are called thrust and radial loads. They are the forces the bearings must endure when the vehicle is cornering or braking. Another force that cannot be measured is the force of the impact from potholes and curbs.

In some cases, you will see a vehicle with a wheel bearing failure that is caused by overloading. Some truck and van owners might be pushing the weight capacity. When a bearing is overloaded, the bearing and rolling elements will run hotter. This damages the grease that protects the bearings. The heat can also damage the seal, causing the bearing to wear prematurely.

If you see a bearing failure in a component that has been recently replaced, ask the owner how they use their vehicle and what they haul.

Loaded Knuckles

A lot of vehicles manufactured by Ford, VW and Toyota are equipped with cartridge-style wheel bearings that need to be pressed into a knuckle. These bearing jobs can be difficult, even if you leave the knuckle on the vehicle and use a special tool to press the bearing.

The latest product to address this job is a “loaded” or complete knuckle that already has a new bearing installed. Eliminating the need to press the bearing can save time. It can also save you the aggravation from wondering whether or not you pressed in the bearing with the correct seal facing the wheel speed sensor. While you can beat flat rate, you can’t make more hours in the day. Loaded, unitized or complete components can maximize your profitability during business hours.

Servicing the Flange

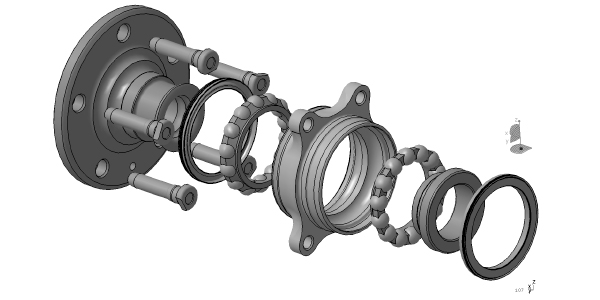

When replacing a press-type wheel bearing and hub flange, it’s important that all the wheel-end parts properly work together after reassembly. Damaged parts or improper torqueing can cause premature hub failure and issues with overall vehicle performance.

A hub flange kit that contains all the components needed to replace a worn-out wheel bearing and flange is a good option if you’re going to do the press work. It’s best to use a kit that includes the hub flange, cartridge bearing, axle nut, seals and c-clip. Follow proper installation procedures to ensure maximum service life for new components.

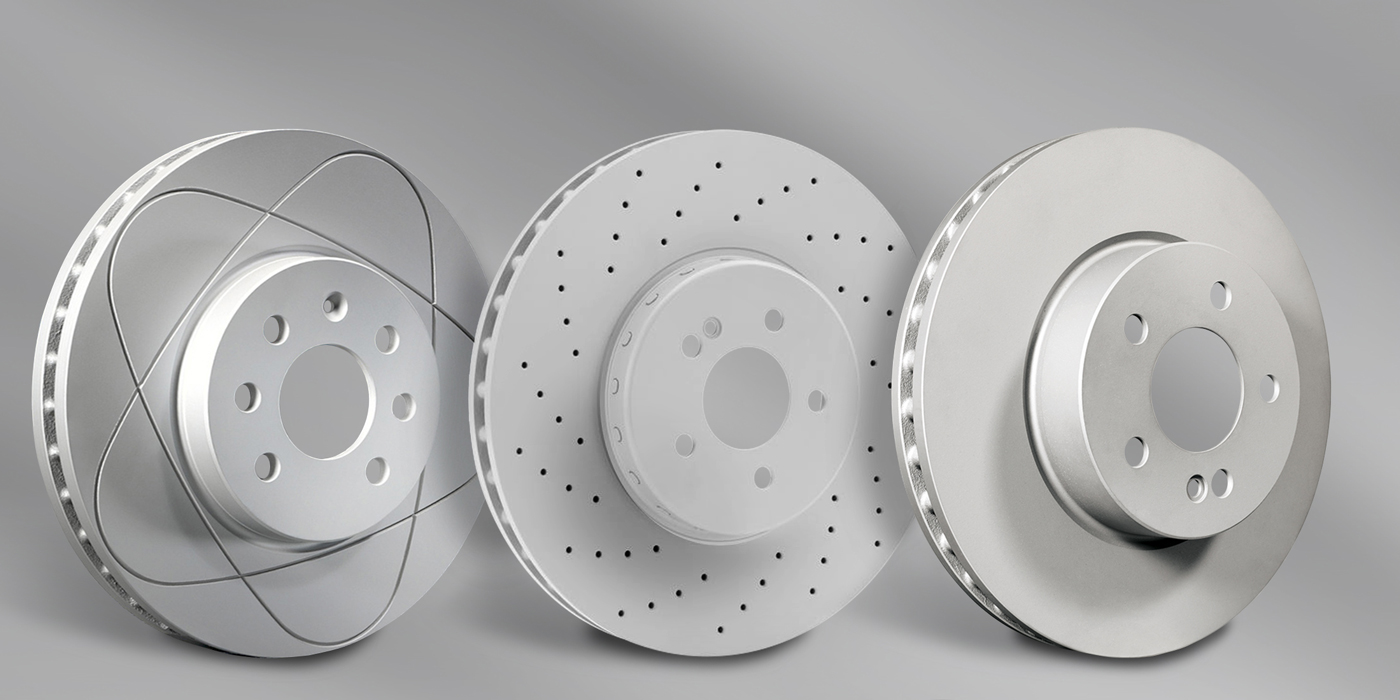

Parking Brakes

In the case of rear wheel bearings, make sure you are researching the information for the parking brake if the mechanism is in the hat of the rotor. The backing plate that holds the mechanism and shoes is often damaged or rusty. For some applications, aftermarket part suppliers have complete assemblies that just bolt onto the axle or knuckle. This can save you time in assembly and sourcing the parts.

Q&A: Diagnosing Wheel Bearing Failure

TR: What is a sign that a wheel bearing is failing?

Hogan: Hub assemblies and bearings can develop excessive endplay and/or a growling noise that can affect vehicle handling or alignment. Check endplay specification and replace the hub assembly if it’s out of specification. Replace or adjust tapered bearings if they’re out of specification.

TR: How can you pinpoint the failed bearing?

Hogan: Remember that bearing failure noise can be misleading. Noise can sometimes occur at the opposite wheel of the failed bearing. This occurs when an overload takes place during driving on the good bearing. A good way to determine bearing noise is to lift the car on a hoist and run the vehicle at a moderate speed. This relieves the overload on the good bearing. Be sure all wheels are clear of hitting the lift. Listen to both wheels with a stethoscope or other recommended listening device. Stay clear of any moving parts. This will help pinpoint the noisy bearing. Remember to check other components that can cause premature bearing wear. Checks should be done on the spindle assembly, axle joints, ball joints, struts, wheel flanges and vehicle frame to look for damage. An alignment may be necessary to identify a bent component.

TR: A new bearing has been installed, but the technician still hears noise. What should they do?

Hogan: Bearing or hub noise that develops directly after installation is usually caused by incorrect installation. A common noise that can develop is clicking while cornering. The clicking noise is created because of incorrect bearing preload. If the bearing is too tight or too loose, it will move internally out of its raceway while cornering.

This is when the bearings are placed under extra stress. Remember that for most hub assemblies, the internal preload for the bearing is created with the axle nut torque specification. An impact gun can add as much as 100 extra pounds of torque to the unit. If this occurs, the internal bearings are set too tightly, and they cannot be readjusted. The hub unit would need to be replaced with a torque wrench and set to the proper torque.

Check out the rest of the March digital edition of Tire Review here.