While the tire market has been soft the last two years, tire development hasn’t slowed, especially in the giant radial OTR sector. We’ll look at the latest tire technologies and how they improve tire performance in the field.

The OTR tire market may have experienced some slowing over the last couple of years but the push by giant OTR radial tire users for faster and more efficient production has remained stronger than ever. This quest for more efficient and profitable operations has kept Bridgestone and the entire tire industry busier than ever before in developing new technologies to enhance the performance of today’s giant OTR radial tires.

You could actually say today’s mantra is Bigger, Stronger, Faster.

We are constantly developing new materials, designs, and processes that will result in incremental improvements in the performance and competitiveness of our tires. This article will address new solutions that Bridgestone is developing or studying to address one of the most fundamental issues facing giant OTR radial tire performance: heat resistance.

Heat is the biggest enemy of an OTR tire. In the quest for “bigger, stronger, faster,” the goal is to manage the amount of heat generated or to remove heat from the tire.

On today’s new vehicles with payloads of 400 tons and top speeds reaching 45 mph or higher, the ability to minimize heat generation and effectively remove heat are priorities.

Heat generation in a radial OTR tire is, at the most basic level, a function of two inputs – load and speed. The load placed on the tire causes deflection of the tire and creates stress on the tire components. Deflection causes movement of the rubber and steel elements in the tire. The faster a tire rotates the more deflection cycles occur in the tire. A portion of the energy required to create this mechanical movement is given off as heat.

You can test this for yourself. Take a rubber band and stretch and release it many times. Notice how much warmer it is? The mechanical energy you imparted to stretch and release the rubber band has been converted to heat energy. This is what takes place in an OTR tire, but on a much larger scale, and all of that rubber (more than 3 tons in a 63-inch radial) – being such a good insulator – holds that heat. Too much heat and the chemical bonds between rubber and other components (steel body plies or steel belts) begin to weaken and break down. If the bonds get too weak the components can separate and the tire is lost.

Chemists are constantly developing new rubber compounds to address heat. New tread compounds are now available that use revolutionary advances in carbon black and other proprietary chemicals developed at the microscopic level to reduce the heat generated by the mechanical work of the tire without sacrificing wear resistance. The result is more productivity and mileage over the life of the tread.

Within the tire, special structural compounds that cover steel components, called skim compounds, are under constant development to increase bonding strength and the ability to maintain that strength at high temperatures. While the chemical advances are significant, the most innovative options to controlling heat have come from leveraging external components that use the environment to help cool the tire.

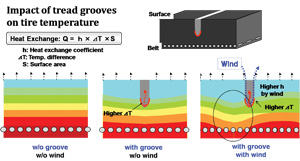

The air that moves over a tire as it rolls down the road is potentially one of the most beneficial ways to control heat and improve productivity and performance. In the same way that a fan blowing over your skin cools you down, this same use of heat transfer can help cool a tire. Cooling the tread of the tire where the rubber is the thickest – it needs that deep rubber to provide good wear and cut resistance – is paramount as the hottest area of a giant radial OTR tire is near the junction between the tread rubber and the top of the steel belts.

Being able to carry heat away from the tread surface allows more efficient internal heat transfer reducing heat build-up at the critical maximum temperature location (see Figure A).

Getting the best possible use of ambient air to cool the tread involves the development of unique grooves in the tread pattern of the tire. Air can be specifically channeled though these grooves to carry off heat. The angle and location of the grooves have been tested extensively in the field and also on special test wheels in the laboratory environment where giant fans simulate “real world” air flow.

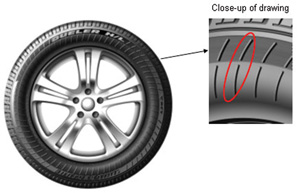

This testing revealed that the maximum air flow and heat transfer occurs by using circumferential grooves. Depending on the depth of the groove, a circumferential groove can offer temperature reductions in the tread of two to three times that of lateral grooves. The proper design of the grooves maximizes the cooling of the tread, and can be integrated into the overall tread design to optimize wear resistance. As an example, these circumferential grooves can be seen in the Bridgestone Verve E3 tire (size 59/80R63) (see Figure B).

The tread of the tire is not the only area where the external environment can be used to provide added cooling. The lower sidewall of a radial OTR tire generates significant heat as the tire deflects under normal operation. In the new world of “bigger, stronger, faster,” this puts additional demands on the sidewall and creates a need for added cooling.

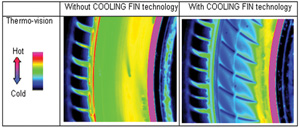

OTR engineers are studying a concept developed and implemented for Bridgestone run-flat passenger tires that uses “cooling fins” on the sidewall (see Figure C). This “fin” technology uses disturbances in the airflow created by the protrusions to cool the tire sidewall.

Under normal conditions, airflow doesn’t really touch the sidewall of the tire; a layer of warmer air forms a boundary just above the sidewall that does not allow the cooler air to reach the rubber. The addition of these “cooling fins” disrupts the airflow, causing it to rise, and sucks the cool air down, allowing it to penetrate the warm air boundary so ambient air can touch the tire. The interaction of the cool air at the sidewall creates a temperature difference and heat is carried away, thereby lowering the temperature of the surface of the sidewall (see Figure D).

Development continues on this new “cooling fin” technology and its application to the giant OTR radial tires may promise additional heat resistance in the sidewall. This temperature reduction helps extend the fatigue life of the tire steel casing ply and the rubber components in the sidewall, allowing the tire to run longer and provide even more value and productivity.

Many new development efforts continue today at Bridgestone and with other tiremakers to enhance and revolutionize OTR radial tires, but new techniques and technology to combat heat will pay some of the highest dividends in extending tire life and delivering greater productivity and value for the user.

Less heat to combat more load, less heat to enhance tire durability and fatigue life and less heat to allow more speed and productivity. That is bigger, stronger, faster.