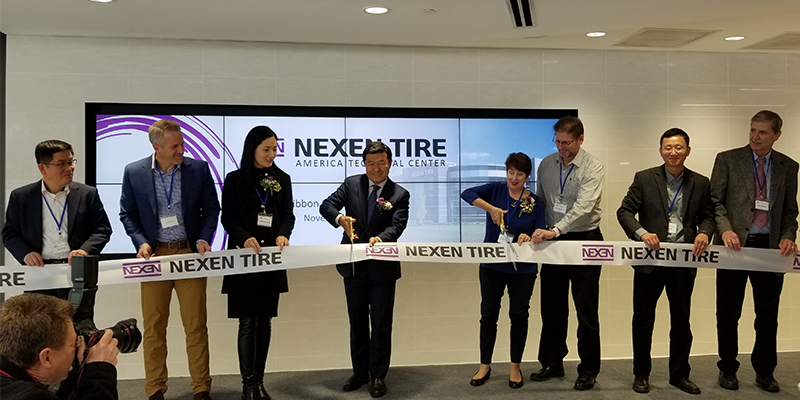

With its sights on becoming a top-tier tire manufacturer set on the not-too-distant horizon, Nexen Tire Corp. put a spotlight on its Technology Center in Richfield, OH, with a grand opening/ribbon-cutting ceremony Nov. 13. The South Korean tiremaker not only showcased its technological muscle inherent in the state-of-the-art facility but also solidified its commitment to the North American marketplace that it feels will fuel even greater success.

Nexen corporate executives, both from the technology center and abroad, local officials and the media were on hand to learn how the Nexen Tire America Technology Center will be integral to the tire manufacturer’s growing presence and brand recognition in the U.S. — something it is taking very seriously as stepping stones to success.

“This is a symbolic moment for our company; 2019 has been a very exciting year for us,” said Travis Kang, Nexen Tire’s global CEO. “Needless to say, Nexen is fully committed to the U.S. market. We are 100% dedicated to our OE customers, our replacement dealers and, ultimately, our end users, who drive on our tires every day. This new technical center is evidence of that commitment. And, what you see here today is the beginning of another exciting journey. It is here in this building that we will design and develop the tire that will help Nexen achieve its goal to be a top tier tire company by 2025.”

The $5 million tech center, designed and constructed by Ray Fogg Building, broke ground in October 2017 and is now fully functional. In the 33,540 square-foot building, tire engineers and designers will create tread patterns, molds, compounds and internal constructions and put their creations under rigorous testing procedures to ensure Nexen’s quality targets are met.

The center’s opening caps a banner year for the company. Earlier this year, Nexen opened its new R&D headquarters, Nexen UniverCITY, in Seoul, Korea. In August, it opened a new state-of-the-art tire factory in the Czech Republic, and in September, the company cut the ribbon on a new tech center in Frankfurt, Germany.

“Very few, if any, tire companies are moving this aggressively,” Kang told the crowd at the Tech Center’s grand opening. “North America has been and will continue to be a key market for Nexen’s growth.”

Since Nexen Tire supplied its first OE tire to a North American factory in 2013, it has supplied over six million tires to its OE customers in North America, becoming “one of the fastest-growing tire companies in the world,” Kang noted.

This technical center is Nexen’s outpost in North America for R&D, said Dean Rogers, Nexen Tire America Technology Center section manager, tire technology. At the center, tires will be designed and developed for the North American market, which has its own unique demands and performance requirements. Rogers said the Nexen Tire America Technology Center will be 50% dedicated to OE tire development; 25% replacement tire development; and 25% future tire technology.

Notably, Nexen Tire America Technology Center has designed and developed the following:

• N’Fera SUR4G Drag Spec for the Dodge Challenger Scat Pack 1320

• Roadian HTX for the 2019 Ram 1500

• Roadian MTX for extreme off-road use

• Tires and sensors (in development) for future EVs and autonomous vehicles

• Groundbreaking new tire for the Canoo EV revealed this fall.

The work the tech center does also filters into the local economy through Nexen’s partners in the tire industry infrastructure, said Kang, noting that this facility has a strong sense of social responsibility for the Richfield community. “Let’s continue to work together and grow together. This building can be an ‘incubator’ – a healthy environment for growth,” he said, adding that growth is also made possible because of the high caliber and expertise of its people.

Bobbie Beshara, mayor of Richfield, was present at the event to participate in the ribbon-cutting and extend her congratulations to Nexen officials.

“We really appreciate your dedication to staying in Richfield, thank you from the bottom of my heart, and I wish you the very, very best in all of your endeavors,” Beshara said before she presented Kang with a present to express her gratitude for the company’s commitment to the city of Richfield.

In closing, Kang thanked Nexen’s customers, suppliers, the Village of Richfield, the State of Ohio, the building designers and construction team, and referenced the company’s management philosophy statement, under which he said Nexen will operate in the U.S.: “We live together for tomorrow with our values embodied in movement.”

Tech Center Tour

After formal remarks, attendees were taken on an extensive tour of the building, with stops in several tire test cells for presentations by various Nexen team members.

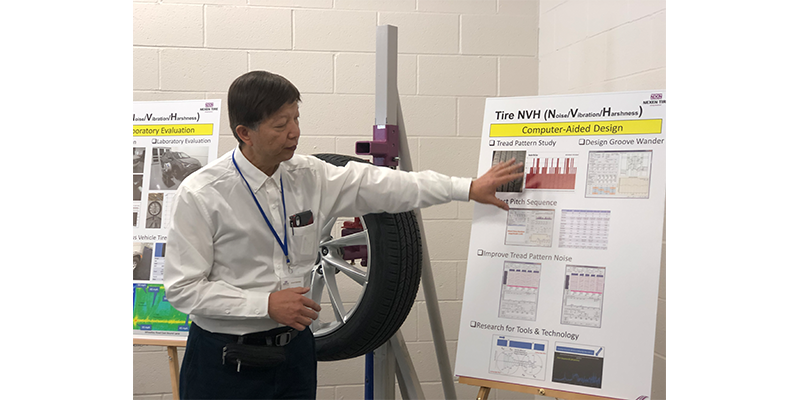

The Noise/Vibration/Harshness (NVH) Lab, for example, strives to achieve excellence in all aspects of tire performance in the areas of noise, vibration and harshness, said Dr. Lin Kung.

“Simulation tools are utilized throughout the development process of every tire tread pattern design. Laboratory and field measurements are routinely conducted as part of the tire development cycle,” he explained. “The NVH team also engages in advanced application research of future tire development in anticipation of future vehicle development such as electric and/or autonomous vehicles, artificial intelligence, and the like.”

One of the charts displayed in the lab detailed that computer-aided design testing for NVH includes tread pattern study, design groove wander, select pitch sequence, improve tread pattern noise and then field and lab evaluation.

Also as part of the tour, Jan Terziyski, program manager, provided an overview of how tires are made (from new design, tire carcass/tread pattern, pattern evaluation, finite element modeling, performance simulation, engineering approval, production, to final product testing), as well as the steps to achieve a snow traction grade and wet traction approval, noting that design efforts are concentrated on simultaneously bolstering performance and boosting customer satisfaction.

Because of the intense work being done to achieve those goals, certain “findings” on specific vehicles are shared with Nexen’s tech center in Korea, in particular, those that relate to stopping distances and rolling resistance/fuel economy. One example is the 2019 RAM 1500 pickup truck that Nexen outfitted with its Roadian HTX RH5, 20-in. tire, which FCA (Fiat Chrysler Automobiles) US LLC said helped its team achieve Motor Trend’s “2019 Truck of the Year” award.

Next up on the tour was a stop at a test cell that will be the future site of a HSU/RR (High-Speed Uniformity/Rolling Resistance) machine, and a final stop to see a tire loading machine used for tire testing and validation of Nexen’s tires for the OE and replacement tire business – the only one like it in the market.

In addition to the new factory in the Czech Republic, Nexen Tire Corporation has three other manufacturing plants – two in Yangsan and Changnyeong, Korea, and one in Qingdao, China. A new North America tire facility is on Nexen’s radar for 2024.

To see a photo gallery from the Nexen Tire Tech Center grand opening, click here.