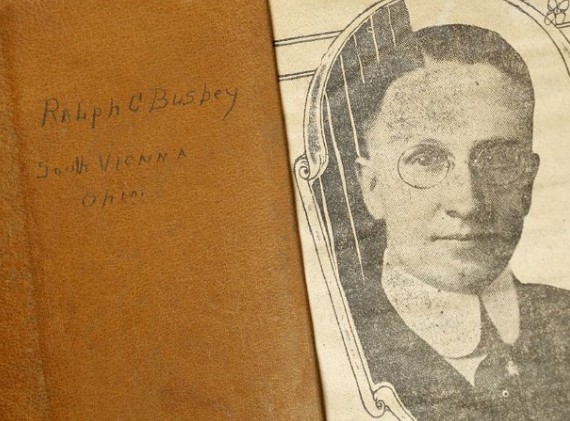

Ralph C. Busbey, a newspaper reporter and one time Akron bureau chief for the Cleveland Plain Dealer, became the third editor of the India Rubber Review (now Tire Review) in 1924. He wrote a section focused on the early days of the Akron rubber industry for “A Centennial History of Akron 1825-1925,” a book published by the Summit County Historical Society 90 years ago. We are proud to say that Tire Review served as part of Mr. Busbey’s core research for his eventual 17,000-plus word essay.

Because of its length, we are presenting Mr. Busbey’s epic in five parts – all this week – and in its original language. Please be mindful that this was written in 1925, so there may be certain words and phrases that were common and acceptable in those days that may not appear so today.

More than half of Akron’s century span of existence has revolved principally around the rubber manufacturing business and its development.

Fifty-five years ago, when the rubber industry was embryonic and unknown west of the Allegheny Mountains, Akron was a smug little municipality of less than ten thousand inhabitants, nestling cozily in the then rather sparsely settled hills of Northern Ohio. Although at that time virtually the hub of the har¬vesting machinery business of the world and the seat of other promising industries, Akron boasted of no great industrial enterprise of such tremendous potentialities as have since been developed by the rubber industry. Its skies then were only lightly sullied by the smoke of industry. The little city had just begun to thrill under the first touch of the romance of industrialism.

That Akron of fifty-five years ago contrasts strikingly with the Akron of today,—the city preeminent as the Rubber Manufacturing Headquarters of the world;—a city of more than 200,000 population ;—a city pulsative with industrial energy and bristling with business vigor;—a city whose rubber and tire factories have a combined acreage of factory floor space today far greater than was the total ground area covered by the entire original city of Akron;—a city which, as the mainspring of one of the mightiest and fastest growing industrial giants known to mankind, girdles the civilized world with its products.

Today more than half of the world’s total production of tires and rubber goods comes from Akron’s mighty industrial institutions where more than 50,000 men and women obtain their livelihood. In Ak¬ron’s rubber factories tens of thousands of light bulbs sparkle as men toil late into the hours of the night, and often all night through, in order to meet the world’s growing demand for Akron’s rubber products. In these factories more than half a million-horsepower of steam and electrical energy are consumed every 24 hours. Here thousands of massive machines grumble and throb, turning out every 24 hours more than 100,000 pneumatic automobile tires and 150,000 inner tubes, fully 150 tons of solid tires for trucks, 15 miles or more of rubberized conveyor and transmission belting, 400 miles of rubber bands, 20 miles of garden and fire hose, miles of railroad air brake and steam hose, tons of rubber couplings, nearly a million rubber heels and rubber boots and shoes for fully 25,000 people in addition to hundreds of tons of more than 30,000 different rubber commodities and novelties. Here the yawning maws of industry are fed more than 150,000 tons of crude rubber and over 300,000 bales of cotton annually, in addition to millions of pounds of chemicals and other supplies. Here employees’ payrolls reach $75,000,000 a year and the revenues from the sales of finished rubber products approximate more than $380,000,000 a year.

As the list of Akron-made rubber articles numbers up into the 30,000 it is of course impossible to enu¬merate them. Let it suffice, therefore, that every rubber article known to the civilized world is made in Akron from the tiniest rubber washer to the mammoth rubberized silken hulls of the Leviathans of the air—the dirigibles Shenandoah and Los Angeles; from rubber bands to conveyor and transmission belts 2,000 feet long, which when rolled for shipment weigh thousands of pounds and stand 8 feet high; from toy balloons to hot water bottles, druggists’ rubber sundries and surgical supplies; and from tire repair patches the size of a quarter to giant pneumatic and solid tires.

It was in 1870 that Destiny, aided by a few of Akron’s progressive citizens, principal among whom was Col. George T. Perkins, (1836-1910) oldest son of Col. Simon Perkins, first began to shape Akron as a mighty city of industry.

Five years after the close of the Civil War, a young man who had served in it as a surgeon but who had forsaken his profession to enter the real estate business in New York, acquired stock in the Hudson River Rubber Co. near Hastings-on-Hudson, as result of a real estate transaction. The location was not profitable and the young owner at the suggestion of a friend came to Akron to investigate advertised factory sites and the availability of inexpensive water power from the Ohio canal.

The young man, then 29, was Dr. Benjamin Franklin Goodrich. His visit marked the founding of the rubber industry in Akron and resulted in the establishment on the banks of the old canal just south of Exchange St., of the first rubber factory west of the Alleghenies. Dr. Goodrich was handicapped by lack of funds. Colonel Perkins had faith in him and in his project and persuaded 18 other Akron business leaders to join him, each loaning $1,000. This sum of $19,000 plus $5,000 from Dr. Goodrich’s real estate partner in the East, constituted the capital of the little company. A small building was secured and manufacturing operations started under the name of Goodrich, Tew & Co. Articles of co-partnership were drawn up on December 31, 1870, with Dr. Goodrich, Harvey Tew, Henry S. Sanderson, Robert Newland and David N. Marvin as members of the company.

The first rubber article produced in Akron was fire hose. Dr. Goodrich before coming to Akron had seen a friend’s home destroyed by fire because the hose was so poor it had burst. In launching his new project in Akron he determined to make a fire hose that would stand up under pressure, and as result this hose, known as “White Anchor,” soon became famous.

The company struggled along for four years when the partnership was succeeded by Goodrich & Company, George W. Crouse providing the timely financial assistance which gave the firm needed working capital and its actual start towards progress and prosperity. In 1879, Alanson Work, father of the company’s present chief executive, became superintendent and to his energy and leadership is ascribed a large measure of the company’s subsequent success.

On May 1, 1880, the B. F. Goodrich Co. ap¬plied for incorporation, the charter being granted May 10 for capital stock of $100,000. The incorporators were Dr. Goodrich, Colonel Perkins, George W. Crouse. Alanson Work and R. P. Marvin, Jr. At the organization on June 16, 1880, Dr. Goodrich was elect¬ed president, Mr. Work vice president and superintendent, and Col. Perkins, secretary and treasurer. The following year Alanson Work succumbed and Dr. Goodrich became superintendent as well as president with George W. Crouse as vice president. Mr. Work’s widow, Mrs. Etta W. Work, was elected to fill his vacancy on the board of directors.

Failing health caused Dr. Goodrich to relinquish the reins of control and go West for his health. He died suddenly on August 13, 1888, Colonel Perkins being elected to succeed him as president. H. C. Corson was elected secretary and treasurer and Dr. Good¬rich’s widow, Mrs. Mary M. Goodrich, was honored with election to her husband’s place on the directorate. Bertram G. Work, the present chief executive, succeeded Col. Perkins on January 10, 1907.

Since its incorporation the company’s vice presidents have been Alanson Work, Col. Perkins, George W. Crouse, H. C. Corson, B. G. Work, F. H. Mason, H. E. Raymond, E. C. Shaw, C. B. Raymond, W. A. Means, A. H. Marks, H. K. Raymond, W. 0. Rutherford, W. C. Geer and A. B. Jones. The company has had but six secretaries—Col. Perkins, George W. Crouse, R. P. Marvin, C. B. Raymond, Guy E. Norwood and F. C. Van Cleef. The treasurers have been Col. Perkins, H. C. Corson, W. A. Folger, W. A. Means and L. D. Brown. The present executive personnel includes Mr. Work as president and chairman of the board of directors; C. B. Raymond, vice chairman of the board; W. A. Means, W. O. Rutherford and Dr. W. C. Geer, vice presidents; F. C. Van Cleef, secretary; L. D. Brown, treasurer and H. Hough, comptroller. Mr. Rutherford now is the president of the Rubber Association of America.

When the Goodrich Company started, the use of rubber products was extremely limited. As compared to the single line of Goodrich production—fire hose—of fifty years ago the company today produces over 35 carloads of more than 30,000 different rubber articles a day, and as compared to the original two-story factory building, the Goodrich factories in Akron consist of more than 60 towering buildings containing over 135 acres of floor space. Sales of the company in 1924 were $109,817,686.

Goodrich ramifications are world wide, with subsidiary and allied factories and selling companies in many countries, and branches in all parts of the world. Goodrich subsidiary and allied manufacturing companies include the British-Goodrich Rubber Co. Ltd., of Leyland, England; the Continental Caoutchouc and Gutta Percha Compagnie, of Hanover, Germany, the largest European rubber and tire factory; the Societe Francaise B. F. Goodrich, Colombes, France; the Yokahoma Rubber Co. of Japan and the Canadian Goodrich Co. Ltd., of Kitchener, Ontario, and the B. F. Good¬rich Rubber Co., S. S. Ltd., of Capetown, South Africa. Selling subsidiaries of the Canadian company are the B. F. Goodrich Co. Ltd., and the Ames-Holden Tire & Rubber Corp. Ltd., while a selling subsidiary of the French company is the Sociedad Anonima B. F. Goodrich of Madrid, Spain. Goodrich factories in Japan were destroyed during the recent earthquake there.

It is interesting to note that one of the original Goodrich employees when the company was incorporated in 1880 still is with the company. He is Percy W. Leavitt who enjoys a record of more than 45 years of uninterrupted service in this one company. Others prominent in Goodrich affairs in the earlier days include Chas. C. Goodrich of New York, John H. Kelly, now president of the Hewitt Rubber Company of Buffalo; H. C. Corson who served for many years as sales manager and who removed to Nova Scotia ; the late Joseph P. Dangel of the hard rubber division; J. W. Kelly, who died a few years ago in Boston; E. C. Shaw, now retired but active in philanthropic movements in Akron; E. C. Tibbitts, for many years advertising manager, and H. E. Joy, E. L. Toy, A. P. Lohman, John F. McGuire, Chas. S. Eddy, Chas. Stacy, A. J. Wills, A. D. Moss, H. A. Bauman, Newton Johnston, Otis Cook and others. When Mr. Corson entered the Goodrich employ as a stenographer in the early seventies, he was one of the city’s few short-hand writers.

The first tires to be made in Akron were solid rubber bands for the wheels of the old fashioned high bi¬cycles, in the early 1880s. The next step in the evolution of the rubber-shod wheel came with the manufacture of solid rubber tires for carriages, followed by the pneumatic bicycle tire. Then came the automobile—the greatest accelerator of the rubber business—and the success of the first solid and pneumatic tires for carriages and bicycles resulted, in 1896, in the production of the first pneumatic tires for automobiles.

From that meager start, with only a few hundred such tires produced the first year, the tire business has grown to gigantic proportions with more than 50,000,000 pneumatic casings being produced in the United States every year—more than half that number in Akron alone.

Goodrich was the first in Akron to make pneumatic tires, and also one of the first to manufacture golf balls, the company having developed the golf ball business to one of commanding proportions today.

The second Akron rubber company had its inception in 1892 when Jacob Pfeiffer, John Grether and John Lamparter, who operated a retail drug store, pooled their savings and entered the rubber business. In a comparatively short time they had lost nearly $50,000 but undaunted started over again, borrowing money to build a 20 x 50 factory. Their combined resources of $250 were used to buy their first case of rubber. The company started making rubber gloves and grew rapidly. William F. Pfeiffer, Jacob Pfeiffer’s brother, and Harvey Miller joined the three on May 1, 1898, and the business was incorporated for $50,000 under the name of the Miller Rubber Manufacturing Co. In 1906, it was reincorporated as the Miller Rubber Co., entering the tire manufacturing business several years later.

Today the company, which started with only $250 resources, is capitalized at $60,000,000. It has 26 factory buildings, over 30 acres of floor space and a capacity of more than 1,000,000 pieces of manufactured merchandise a day, with daily production exceeding 100 tons. Jacob Pfeiffer is president, William F. Pfeiffer is secretary, treasurer and general manager. Other officers include: C. T. Grant, vice president; R. R. Jennings, comptroller and assistant treasurer, and Charles R. Wetzel, assistant secretary. F. C. Millhoff is general sales manager. The company’s sales in 1924 were approximately $30,000,000.

Akron’s third rubber company was launched in 1894 under the name of The Sherbondy Rubber Co., under the leadership of Ohio C. Barber, president of the Diamond Match Co. and founder of the city of Barberton. The company was formed to operate in the plant across Failor St., from the Goodrich factories, vacated by the Diamond Match Co. when it moved to its new quarters in Barberton. The company began the manufacture of bicycle tires and drug specialties. In 1896 the name was changed to the Diamond Rubber Co. when it began the manufacture of automobile tires. Three years later, the company was joined by A. H. Noah as secretary and treasurer. In 1898 the company increased its size and F. A. Hardy and W. B. Hardy of the Revere Rubber Co. and W. B. Miller and A. H. Marks joined Mr. Noah in active management.

Mr. Marks in 1899 invented a new alkali process for reclaiming rubber and the Diamond Rubber Co. established in South Akron a reclaiming plant. This concern grew rapidly and in 1904 Diamond and Goodrich united in forming the Alkali Rubber Co. to carry on the reclaiming business under the Marks patents. The Diamond Co. added steadily to its lines of products and in 1912 merged with the Good¬rich Co., the latter buying it for $45,000,000 and increasing its own capitalization from $45,000,000 to $90,000,000. Prominent in the Diamond organization were many men who were afterward prominently identified with the Goodrich and other companies, including A. H. Marks, W. B. Miller, A. H. Noah, O. S. Hart, David Galehouse, I. R. Bailey, O. J. Woodard, C. B. Myers, James D. Tew, N. S. Noble, A. L. Pardee, H. E. Riker, G. E. Norwood, Theodore Weigele, A. B. Jones, Dr. D. Spence, George Oenslager, James Cutler, John Noonan, Thos. S. Lindsay, Mark Roe, James A. Braden, F. I. Reynolds, L. G. Fairbank, H. M.