When a customer pulls in with a complaint about brake pulsation or judder, throwing parts at a repair will not solve the problem.

When a customer pulls in with a complaint about brake pulsation or judder, throwing parts at a repair will not solve the problem.

New brake pads and rotors do not solve pulsation, judder or premature wear problems – they only mask the root cause for a short period of time. In fact, the only problem new pads and rotors can solve is the elimination of parts that are below specifications.

Looking at the big picture of the measurements, vehicle and driver together is the only way to solve a customer complaint when it comes to brakes. Having the knowledge of what is happening between the rotor, pad and caliper is also key.

Pulsation and DTV

The main culprit with pulsation problems is variation in disc thickness, or parallelism.

The two friction surfaces of a rotor are designed to be parallel to one another within a set specification. The allowable tolerance is known as parallelism. It is also known as the rotor’s disc thickness variation, or DTV. In order for the pad to stay in contact with the rotor, the piston must extend or be pushed back into the housing as force is applied. This creates the pulsation in the pedal that is most noticeable to the driver in how the pedal feels.

Every time the low spot passes by the caliper, hydraulic pressure at the caliper drops. This produces less braking force as this area passes by the pads. It can also affect braking distances.

Lateral brake runout means the rotor wobbles from side to side when spinning. Think of it as the rotor or flange moving in a plane that is not the same as that of the pads or caliper. Lateral runout will cause the rotor to contact the brake pads, knocking them back as the high spot of the runout contacts the pads. This allows more pedal travel before the pad’s surface makes contact with the rotor.

Judder and BTV

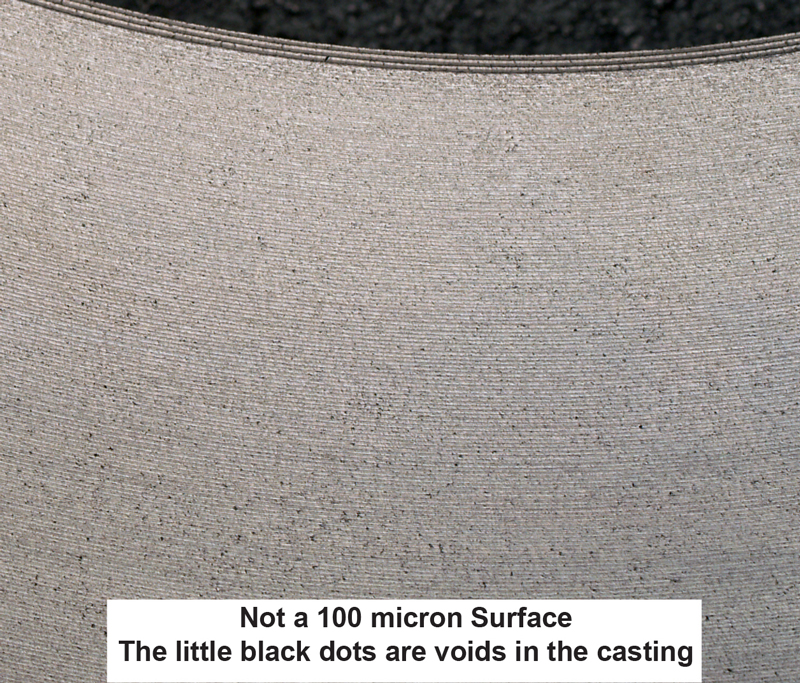

Judder is a vibration that can be felt in the seat or steering wheel, but it will not cause pulsing of the brake pedal in most cases. Judder can occur in a vehicle with zero runout or DTV, and is caused by brake torque variation (BTV). BTV occurs when there is a variation of torque across the face of the rotor that causes the rotor to slip and catch as brake pads pinch the rotor. BTV may be caused by an inconsistent rotor finish, metallurgy or uneven deposits of friction material on the face of the rotor.

Knowing the difference between pulsation (DTV) and judder (BTV) is critical to solving any brake complaint and avoiding a problem in the first place. Assuming that new pads and rotors will automatically fix the problem will only create more issues with the customer when the vehicle inevitably comes back.

Rotor Finish and Transfer Layers

The friction between the two surfaces changes forward motion and braking force into heat. But, there is a lot of science that goes into what happens at the molecular level to make that happen.

Most semi-metallic brake pads use the two different surface materials of the pad and rotor to make friction. The abrasive action wears away the two surfaces.

Ceramic and some NAO pads transfer a thin layer of pad material onto the surface of the rotor. The transfer layer is bonded to the rotor’s surface and cannot be washed away by water or wheel cleaners. The only way to remove it is by using a brake lathe or abnormal heat. With this type of pad, it is critical to machine the rotor with the correct surface finish and follow the recommended break-in procedure so the transfer layer can be established.

Adherent friction is easier on rotors, but the pads become the primary wear component. The layer is always being worn and replenished by the brake pad during braking, so these pads produce dust. The smoothness of the friction surface of a rotor is described in terms of microfinish or RA factor. RA stands for “roughness average” and represents a way to measure the smoothness of a rotor. Most lathes on the market will yield very acceptable RA factors when they are in good condition and are used properly. The finish is essential to transfer material for organic and ceramic friction materials. The correct finish is also essential for semi-metallic pads so they can have the correct coefficient of friction during initial break-in.

Shut Up and Listen

Have you ever worked with a guy who has all the answers? When you say, “My neck hurts,” he will say, “You need a new mattress.” This type of person never listens or asks questions; they just offer a constant stream of advice. Just like with your coworker, when it comes to discussing brakes, shutting up and listening is often the best solution.

However, there is one golden question every service writer must ask the customer before recommending any brake service: “What difference have you noticed in your brakes recently?” This line of questioning forces the person to explain how their brakes feel, sound and perform, which provides important clues as to what the system needs.

The secret is to be quiet and listen, as the customer will tell you almost everything relevant to the repair that you need to know.

Be ready to ask follow-up questions to get more information like:

• Is it doing it all the time?

• Has it gotten worse?

• When did you notice it?

Keep the questions as broad as possible, and just let the customer unload their problem. Make sure you take notes and put them on the repair order. Next, reflect on what was said. This will build a level of trust much better than if you gave them the most technical explanation of the history of disc brakes.

If the service writer has done his job, the technician will know four things:

1) If there is a pulsation or judder;

2) Where the pulsation or judder is coming from (steering wheel, seat or pedal);

3) When the pulsation or judder occurs, and

4) If there is a noise problem.

If the customer says his rotors are warped, it can mean a number of things. Warping is a diagnosis, not an observation or symptom. This is why asking them where and when a vibration is felt is critical to the diagnostic process.