Have you ever broken a TPMS sensor trying to remove a corroded nut, or completed a TPMS service only to have the customer come back due to a slow air leak? There is a good chance that corrosion is to blame.

Corrosion happens because of one or two reasons:

1. Dissimilar metals are being used.

You should use only brass- or nickel-plated valve cores in brass valve stems. If a brass valve core is used in an aluminum valve stem, the metals will react and cause corrosion, making it difficult to remove various parts of the service kit necessary for servicing the system. Without replacement, this can cause the service kit to not function properly and potentially cause slow air leaks.

2. Northern and Midwest winters bring with them many road elements that contribute to corrosion, like salt and dirt.

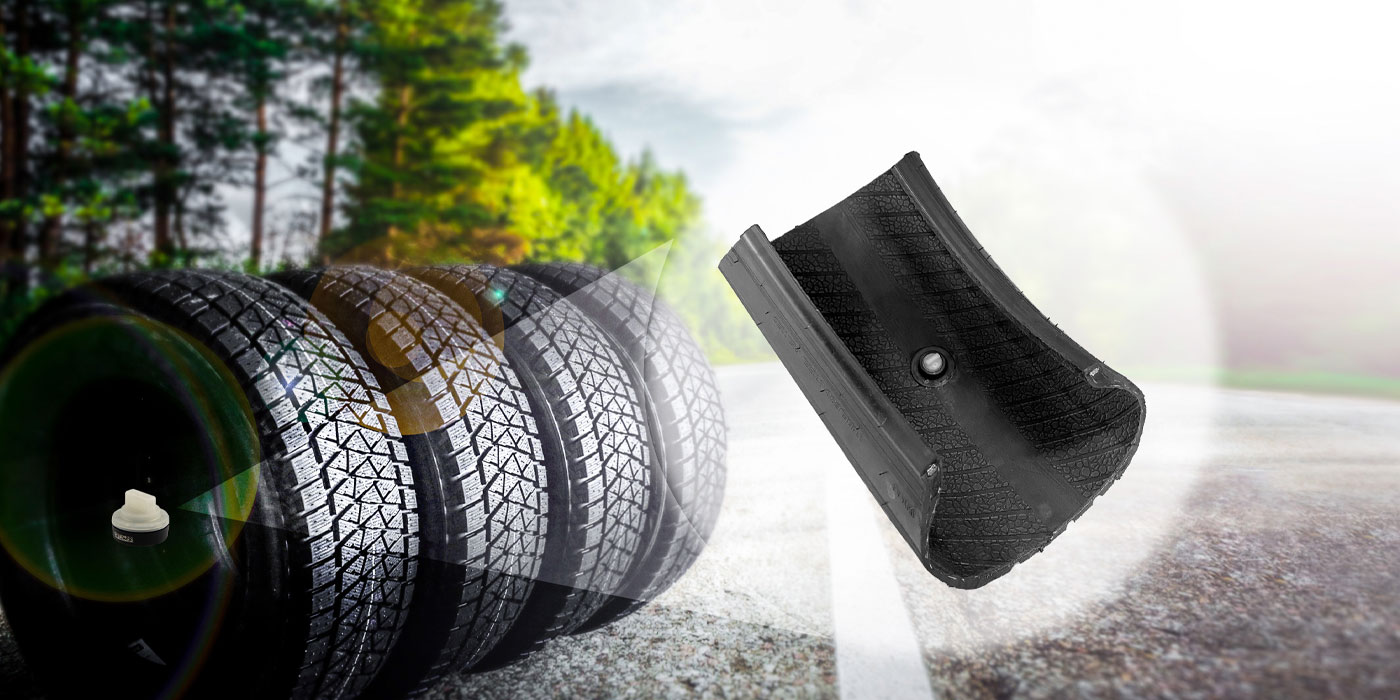

These elements cause metals to break down, resulting in corrosion, an especially important topic around spring tire changeover season. A number of winter wheels just made it through the harsh road elements associated with the winter season and are entering the shop for their annual changeover to all-season tires. As easy as it would be to remove the winter tires, install the all-season tires and send the customer on their way, that approach is often met with some disappointing and inconvenient comebacks due to slow air leaks associated with corroded or damaged service kits. Whether the driver owns a full wheel and tire set and needs the TPMS sensors switched over, or if they use the same wheels and just switch tires, the service kit on the sensor should always be replaced when the tire is removed from the wheel during service.

Consistently changing out service kits should be a standard practice at any shop that services tires and TPMS systems. Many OEMs recommend changing the service kit every time the tire is removed from the wheel. Removing and reinstalling an old service kit often leads to slow air leaks and costly comebacks. Replacing service kits is an easy, affordable way to ensure the best service possible for your customer.

There are also times that you should consider replacing a service kit, even when the tire is not being removed from the wheel. Specifically, after long winters, you can see when a valve is showing signs of corrosion. Rust and damage will show on the exposed side of an aluminum clamp-in valve, and cracking will appear on a rubber snap-in valve. These signs should prompt a change in the service kit. If you see that valve caps are missing, check that the valve core is in good condition, but it is very likely that salt, dirt and grime have already compromised the integrity of the valve, and it should be replaced. A best practice would be to walk customers around their vehicle and show them these signs of corrosion so that they can see it for themselves.

Quick Tip: Seeing is Believing

Keep a jar or pail of corroded sensors and service kits at the counter as a talking piece. If you can show a customer the physical signs of corrosion and explain the impact it can have on keeping air in the tire, the service should really sell itself. This will help turn the conversation into a “must do” rather than an optional add-on to their tire service.

Jacki Lutz is the Global Head of Communications, Training and E-Commerce for Schrader TPMS Solutions, a global leader in TPMS. She is a TIA ATS instructor and serves on a variety of industry boards.

Check out the rest of the March digital edition of Tire Review here.