As a dealer, you are already familiar with the fact that renewable materials from plants are used in the production of some tires.

Natural rubber, which comes from latex collected from rubber trees, is one of them. Another is rayon, which comes from plant cellulose. Rayon is used as part of the carcass, a reinforcement to carry the load of a vehicle and the inflation pressure your customers hopefully check every month.

But as science and technology move ahead at increasing speeds, alternative renewable plant-based materials are being used by tire manufacturers. These are being employed not only to further reduce their environmental footprint, but also to deliver improved performance benefits to consumers.

Green tires, as you know, provide greater fuel economy via their low rolling resistance. By employing some new materials, including plant-based components, fuel economy can be enhanced without sacrificing performance.

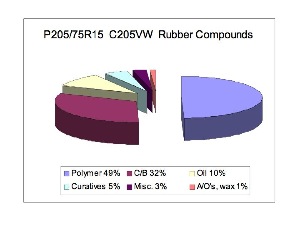

One such type of alternative renewable material is orange oil as developed by Yokohama. A typical modern passenger tire is comprised of approximately 80% rubber compounds, 10% steel, 5% textile and the rest is chemicals of many types. Rubber compounds are a mix of approximately 60% polymers and oil (see Figure 1).

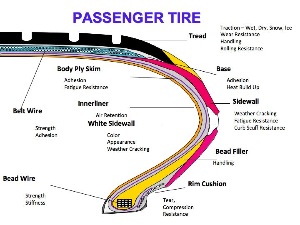

The largest volume of rubber compound is the tread, so it made sense for engineers to look at oil as a candidate for renewable alternative material advantages. Oil – primarily as synthetic rubber – is used in tread compounds to adjust the hardness of the tread, providing a balance of traction, handling, ride comfort and crack resistance (see Figure 2). Oil also provides improved processing of uncured tread, making it easier to form the rubber into correct dimensions for tire building.

Additionally, oil allows some extension of more costly polymers, which makes the tread more economical to produce. The challenge is to balance the multiple demands of performance, cost and complexity.

What Orange Oil Does

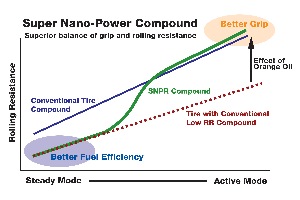

By combining orange oil with natural rubber, the two form an excellent bond that results in a new compound Yokohama has termed Super Nano Power Rubber. SNPR creates a balance in what has conventionally been a trade-off in tire development, delivering superior grip while providing excellent low rolling resistance.

Rolling resistance and traction (especially wet traction) are frequency (vehicle speed) dependent. Rolling resistance depends on ~10 Hz (rolling frequency of the tire) but wet sliding frequency depends on ~1,000 to 10,000 Hz (vibrating rubber that is sliding across small bumps in the pavement – the smoother the surface, the higher the frequency).

Both rolling resistance and wet traction are hysteretic processes; this means that both depend on turning energy into heat. Orange oil, the engineers found, provides a “dual-mode” characteristic. At slow speeds, orange oil does not generate much heat – low viscosity at slow speeds, so rolling resistance is low. At high frequency, orange oil is viscous and turns vibration energy into heat energy, an energy loss that provides traction.

To help explain the benefits of orange oil in terms consumers can easily appreciate, think of dual-mode as having a “steady” mode and an “active” mode. During steady mode (straight driving), when heat generation is comparatively less, the SNPR works to ensure low rolling resistance. During active mode (cornering and braking), the orange oil properties generate heat quickly to deliver better grip (see Figure 3).

In other words, orange oil technology responds to the way a person drives – delivering the best of two worlds (performance and fuel efficiency) without compromising on either.

Like many tire technologies, orange oil science was developed on the track; the Advan ENV-R1 has been used in the American Le Mans GT3 series and was succeeded by the second generation ENV-R2 in 2010. From the track, the technology was successfully transferred down to passenger car tires, specifically the dB Super E-spec performance tire.

Alternative Liner

The quest for the application of new technology never stops and adding alternative materials and design concepts that help the environment is a great win-win situation. So what’s next?

Tires need air pressure to support the vehicle load. In the previous cross section illustration (see Figure 2), you can see the inner liner is the component that works to retain pressure inside the tire.

Engineers have investigated how to reduce this material to save weight, reduce rolling resistance and reduce the amount of oil in a tire – all without sacrificing innerliner performance.

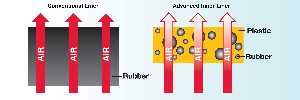

One avenue explored was actually quite simple – plastics. After all, plastic is used to seal air from food to prevent spoilage. Working with researchers, the engineeers found a way to make an alternative plastic-like material that was compatible with tires, the tire manufacturing process and the demands a tire faces in service.

The end result is Airtex Advanced Liner, an ultra-thin sheet of rubber and plastic with good air pressure retention properties. Depending on the ratio of plastic to rubber and the thickness of the material, the product can be adjusted to achieve lower rolling resistance with desired air retention capability.

With the combination of good inflation retention and Airtex’s weight savings (only one-fifth as thick as conventional butyl liners), drivers can make fewer trips to the gas pump.

To help illustrate the benefits of this new inner liner technology, according to the Automobile Club of Southern California, a motorist who drives an average of 12,000 miles annually on tires that are underinflated by 5-8 psi is wasting up to 50 gallons of gasoline – $141.50 (at $2.83 a gallon) a year. That’s more than half the cost of a week’s worth of groceries ($226) for a family of four, according to the U.S. Department of Agriculture. If there are two drivers in the family, that total comes to $283, well over a week’s worth of food for the family.

Reduced Environmental Footprint

Alternative materials like orange oil and rubber elastomer/resin aren’t just good for consumers and shop owners, they also are good for the environment.

Unlike petroleum, orange oil is a renewable material. And orange oil is extracted from the part of the fruit that is a by-product to begin with: the orange peel. This means that the use of orange oil lends to recycling while avoiding any negative impact such as reducing the food supply or destroying land to meet increased demand.

Additionally, the improvement in fuel efficiency achieved by alternative materials such as Airtex presents environmental benefits. Every gallon of gas saved by the innerliner technology means 20 fewer pounds of CO2 released into the atmosphere.

What Else is There?

Nano-technology, the design of materials and structures at the molecular level, may well be the next great frontier in tire science. Integrating electronics, mechanics, chemistry etc. will also provide many cutting-edge technologies for tires in the future.

Tires that use 100% of their available molecular level properties to enhance tire performance and reduce the amount of material required are in design and use now. Tires that can respond to their environment intelligently via electronics working directly with compounds and reinforcements will benefit the driving performance of future generation tires.

Combinations of traditional and alternative materials will always be on the minds of scientists and engineers because advantage rules the marketplace. And for the consumer, the advantage comes from the application of new ideas to meet real world needs – including the environment.

By Theresa Palang and Dan Guiney, Yokohama Tire Corp.