Valve corrosion is often the culprit of slow air leaks after a tire service. More specifically, galvanic corrosion can occur when the valve is exposed to outdoor elements such as the road grime, dirt and salt. These elements create a chemical reaction in the metal, causing nuts or valve cores to bond with the stem and rubber components and then warp. For this reason, climate can often play a large role in the number of corroded valves that come into your shop. These chemical responses can lead to those frustrating slow air leaks that result in customer comebacks, costing your shop time and money.

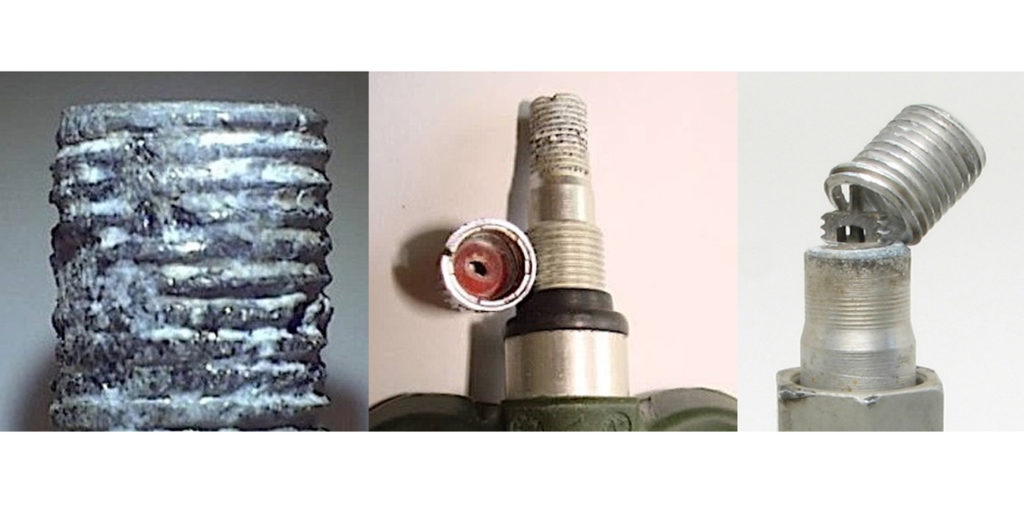

Servicing a corroded valve can be challenging and often leads to replacing the entire TPMS sensor if the valve is irreplaceable and permanently fixed to the sensor. This is why it is so important to spot a corroded valve before you begin service. The easiest way to identify corrosion is to look for any discoloration or physical damage to the valve stem on the outside of the tire. If there is no valve cap in place to protect the valve, a good place to spot corrosion is around the valve core. Corrosion is also often found under and around the nut.

If you don’t see any visible signs of corrosion, you can slowly start to loosen the nut or valve core. If either one seems stuck, then the valve is likely corroded. Breaking the nut or valve core may be inevitable. Regardless, the service pack or serviceable components of a TPMS sensor should be changed before turning the vehicle over to the customer. As mentioned, in some cases, the valve stem is irreplaceable or a fixed component of the sensor. If this type of valve shows signs of corrosion, you may want to advise the customer to replace the entire sensor on the grounds that corrosion often leads to slow air leaks. In the long run, they would save time and money and ensure the effectiveness of their TPMS system if they replace the corroded sensor during that initial service.

In addition to corrosion, the valve and its components often get knocked around and damaged during tire service. To avoid comebacks, Schrader recommends changing the service pack every time the tire is removed from the wheel. Including service pack replacement in your shop’s standard operating procedure is an easy way for you to ensure your customer leaves with a working TPMS system every time.

What’s in a TPMS Service Kit?

While most TPMS service kits come with a valve core and cap, components can differ depending on whether the sensor is a snap-in or clamp-in model.

Components that come with a snap-in sensor service kit include the valve core, rubber stem, plastic valve cap and torque screw. Clamp-in sensor service kit components include the valve core, rubber grommet, plastic valve cap, torque nut, aluminum stem (for replaceable valve) and a torque screw (for replaceable valve).

Jacki Lutz is the Gobal Head of Communications, Training and E-Commerce for Schrader TPMS Solutions, a global leader in TPMS. She is a TIA ATS instructor and serves on a variety of industry boards.