Over the past several years, many vehicle manufacturers have started moving away from aluminum clamp-in valve stems and switching to rubber snap-in valve stems instead. The main reason for this switch is that aluminum clamp-in stems are more susceptible to corrosion than their rubber counterparts; especially in certain climates and locations where the valve stem is frequently exposed to salt, sand, humidity or road grime.

Corroded valve stems are a problem because they lead to larger issues like slow air leaks and broken parts during the repair process when they corrode themselves to the wheel rim. In addition to corrosion issues, when the rubber grommet of a clamp-in stem is originally installed, it fuses itself to the inner wall of the valve hole and hardens in that shape to lock in air. When the tire is deflated for service, the hardened grommet can shift and not re-fuse properly, again causing slow air leaks. It is for these reasons that the general best practice is to replace aluminum service kits every time the tire is removed from the rim.

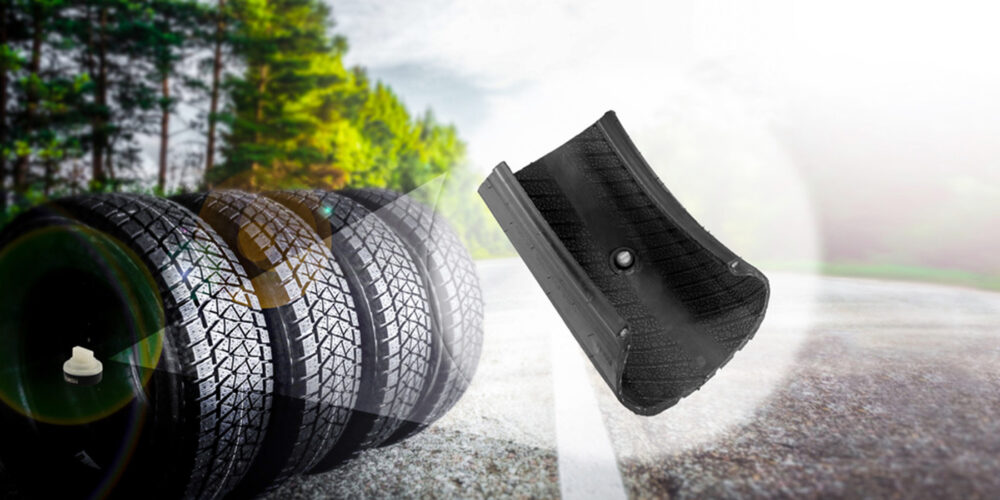

Rubber snap-in stems offer a corrosion-resistant solution for OEMs and some repair benefits for the aftermarket. In addition to being more resistant to corrosion, rubber stems have fewer parts and are arguably easier to install and remove. Rather than needing a nut to “clamp” it into place with a torque tool, a rubber stem is installed with a valve puller tool, and the stem is quite literally pulled through the valve hole of the rim to set it into place. Likewise, to remove the rubber stem, the technician uses the same valve puller to pull the valve completely out of the valve hole. No twisting, turning and breaking of corroded nuts.

However, although the rubber snap-in stem is more resistant to corrosion, it isn’t entirely damage-proof and should still be replaced each time the tire is removed from the wheel. The rubber on the stem can begin to dry out, harden, and in severe cases, crack as it is exposed to the elements, especially UV rays. A used rubber stem is almost always damaged during repair because the hard, dry rubber must be pulled through the rim hole completely to remove the stem. The stem usually cracks or rips as it is forced to fit through the valve hole. Although the tears and damage are not always obvious on the stem, there is enough damage to the stem to cause slow air leaks.

The best way to protect your driver from slow air leaks, and to protect your shop from costly comebacks, is to make it a habit to always change out the service kits every single time the tire is removed from the rim. Regardless of if you are using an aluminum stem or a rubber stem, there is usually enough wear and tear to justify a new service kit. In general, service kits are also relatively inexpensive, and the cost should automatically be included and considered a vital step in a TPMS repair service.

Jacki Lutz is the Global Head of Communications, Training and E-Commerce for Schrader TPMS Solutions, a global leader in TPMS. She is a TIA ATS instructor and serves on a variety of industry boards.