GM’s GMTK2 platform was introduced in 2014 as a replacement for the GMT900 platform. The platform is used for all full-sized pickups, SUVs and commercial trucks. The brake system is a byproduct of what they learned from the system on the GMT900.

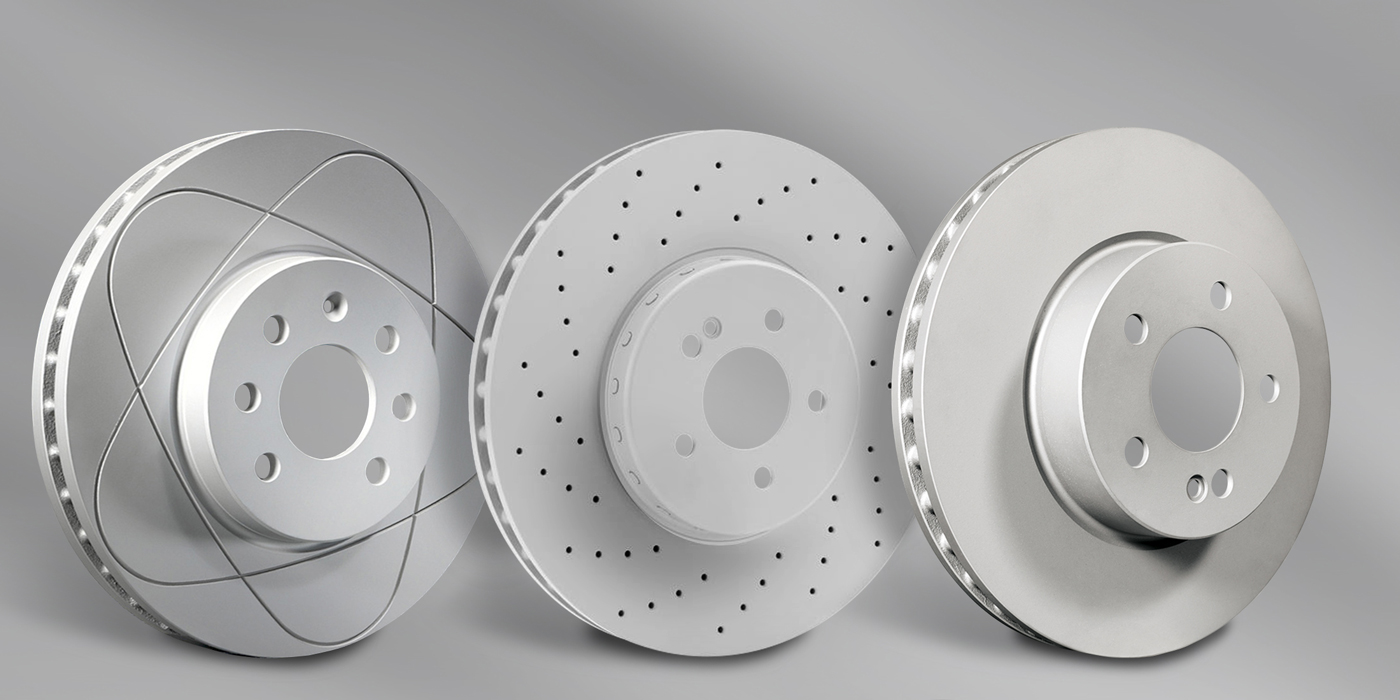

There are three brake packages for the GMTK2 — The JD9 is found on 1500 Series trucks and SUVs; the J95 is on the 2500 Series trucks; and, the J96 is found on 3500 Series dual-wheel rear axles.

Front Brake Calipers

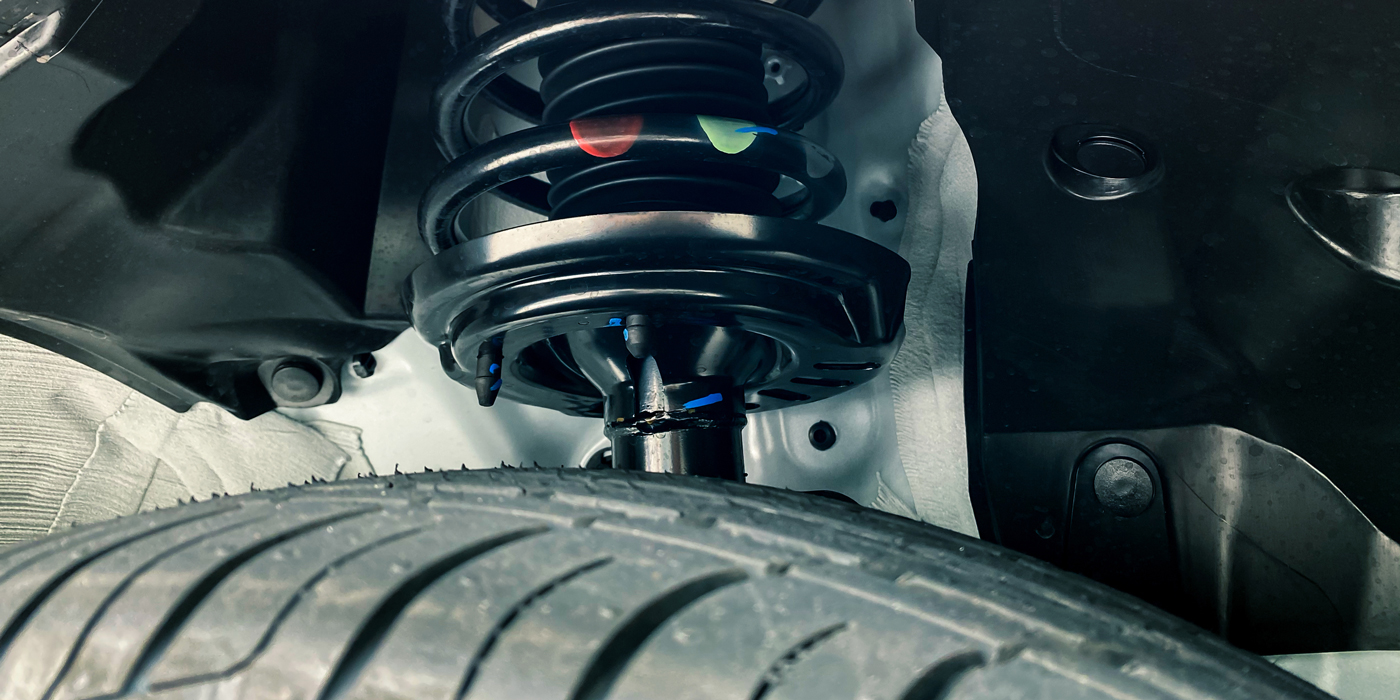

On the 2500 (J95) and 3500 (J96), the caliper guide pin and bushing designs are different than what can be found on the 1500 (JD9). To remove the caliper body from the bracket, the caliper bracket must be taken off of the vehicle. On the inboard side of the brake caliper, a cap and a collar are located on the outboard side. If these are damaged, they can allow water and debris to get inside and eventually cause the caliper to seize.

Only on the 2500 and 3500 Series, the caliper guide pins and caliper bracket bolts use a thread-locking compound, so they can be difficult to break loose. Clean the old compound from the bolts before applying new thread-locking compound. Match the color and coverage with the fresh compound.

On the 1500 JD9 brakes, the caliper guide pins are bolts and the pins go into the caliper and bracket. The good news is that the GM service information does not require thread-locking compound on the caliper bracket bolts.

Rear Brake Calipers

On the 2500 and 3500 with the J95 and J96 brake package, the rear calipers are a smaller version of the front brakes. To remove the caliper body from the bracket, the caliper bracket must be off the vehicle. Like the fronts, on the inboard side of the caliper are a cap and a collar on the outboard side. Only on the J95 and J96, the caliper guide pins and caliper bracket bolts use a thread-locking compound.

J96 Rear Rotors

The 3500 J96 brake package has a floating rear axle with the dual rear wheels. Changing the rotors requires service to the wheel bearing hub. It should be standard practice to replace all the seals and maybe even the adjusting nut. The eight nuts that hold the rotor to the hub should have fresh thread-locking compound and be tightened to 148 ft./lbs.

Parking Brakes

All the versions of the GMTK2 platform use pedal-operated parking brakes. The pedal assembly is a spring-loaded ratcheting assembly. It adjusts the travel of the pedal as the cable stretches and the shoes wear to a lesser degree. When you remove a parking brake cable on the rear parking brake assembly, the spring tries to take up the slack.

To lock the pedal, GM recommends having one technician pull the pedal forward until the brake cable pedal drum reaches the full reset position. A small screwdriver should be inserted into the hole on the side to lock the drum in position so the rear parking brake cable at the wheel can be detached.

Using a brake pad that uses adhesives or other methods to secure the friction material can compromise the safety of the brakes during a panic stop and in the future as corrosion breaks down the bond between the backing plate and the friction material.

The parking brake shoes must be adjusted before the parking brake cable tension is adjusted. This is done with a shoe-to-drum gauge. Use the gauge to position the shoe so that it contacts the inside diameter of the rotor. Once on the vehicle, turn the adjuster nut until the lining just contacts the rotor. The clearance between the park brake shoe and the rotor is 0.6604 mm (0.026 in).

When everything is assembled and adjusted, pull the pedal forward and remove the screwdriver. Depress the pedal three times to adjust the cables.

Brake Pads

The original front brake pads from the factory use mechanical retention to attach the friction material to the backing plate. Using a brake pad that uses adhesives or other methods to secure the friction material can compromise the safety of the brakes during a panic stop and in the future as corrosion breaks down the bond between the backing plate and the friction material. GM specified mechanical retention due to the weight of the GMTK2 platform and the size of the brake pad.

False Brake Fluid Leaks

In March 2018, GM issued bulletin PIT5479A about the appearance of brake fluid leaking from the caliper piston area. The bulletin covered 2014-2016 1500 Series vehicles (JD9 brake package) on the GMTK2 platform. The bulletin states that some calipers might look like they have brake fluid leaks, but the explanation is that this is merely excess assembly grease. GM says the excess grease can be cleaned off.

Check out the rest of the January digital edition of Tire Review here.