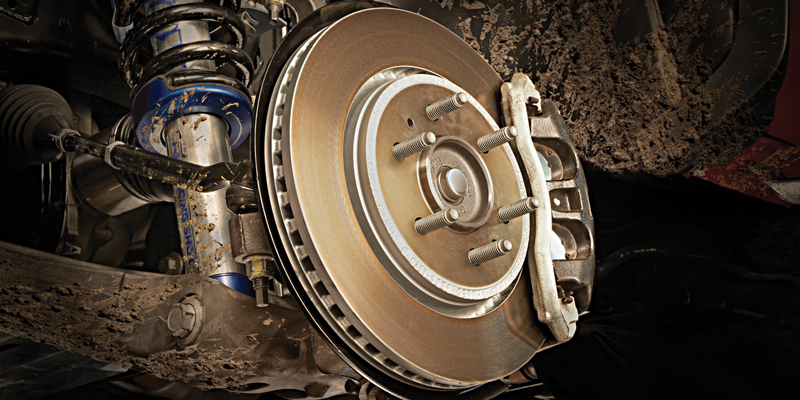

Brake Hose Inspection Tips to Spot the Problem Before It’s Too Late

There is no recommended replacement interval for brake hoses. That’s because brake hose conditions will differ depending on the vehicle, driver, and environment. Inspection is the only way to spot a problem before a brake failure.

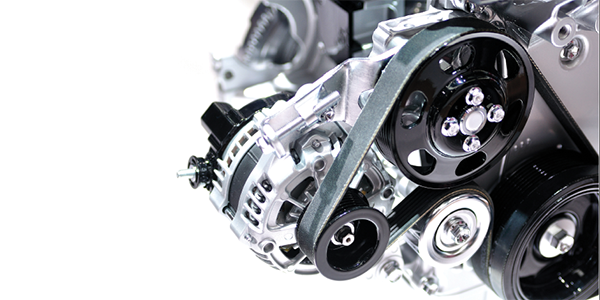

Belt Inspection Checklist

You might have only one chance to sell a customer a new serpentine belt. With belts lasting roughly 90,000 miles, proper inspection at the time of failure is critical not only for selling the belt, but also for ensuring add-on sales and better customer satisfaction.

These are the steps you should be performing on every car or truck that enters your shop.

The Proper Way to Diagnose and Reset TPMS Systems

The tire pressure monitoring system’s (TPMS) primary function is to make the driver aware of the state of tire pressure within the tires. Under normal system operations, the TPMS system will alert the driver when one or more affected tires PSI reading falls below 25% of the vehicle’s placard. When the tire sensor indicates “low tire pressure,” it sends a radio frequency (RF) signal of 315 or 433 MHz to the ECU on the vehicle that determines if the pressure is below the threshold, which then will indicate a TPMS symbol or position-specific display, depending on the vehicle.

Going Vintage and Outfitting Classic Cars with Modern Tires

Summer is here. On any given weekend, you’ll find the proud owners of classic cars touring the countryside, parked at competitions, or showing off at cruise-in events. Thanks to the increasing numbers of classic car enthusiasts including Baby Boomers, this niche tire segment is growing.

AAA to Rescue 7 Million Drivers This Summer

AAA is projecting that 7 million American drivers will need its assistance during the 2017 summer season, with the majority facing battery, lock and tire-related issues.

Finding the Leak

You’re pretty sure your customer’s vehicle has a leak, but what’s the best way to find it? When the source of a leak isn’t obvious, leak detection can be one of the most frustrating automotive service challenges. However, with the proper tools and equipment, a fast, safe and reliable diagnosis and location identification of the leak can bring about a profitable repair and a satisfied customer.

Video Maintenance Minute: Tires and Bushings

It’s important to service bushings properly. If the bushing is installed incorrectly, it can lead to vibration issues and failing parts.

Struts: The ‘Loaded’ Question

What can you do in 17 minutes? You could make money on those 17 minutes of billed labor installing traditional struts – or you can give up those 17 minutes to sell a more profitable part that has the potential to lower the chances of a comeback and give the customer more value.

Do’s and Don’ts of TPMS Installation and Maintenance

With millions of vehicles expected to need TPMS sensor replacement, it’s important to know what is involved with the replacement, installation and relearn of TPMS sensors.

Video Quick Tip: Shocks and Struts

Quick Tip: Shocks and struts may look okay on the outside, but it’s what’s on the inside that counts. Make sure to take a vehicle for a test drive to feel if components have worn down. A worn shock or strut is no longer able to control the wheel or suspension, leading to body sway, loss of control and even increased braking distances.

Scrub Radius and Alignments

Custom wheels and oversized tires can look good and give a vehicle a unique appearance. But it’s what you can’t see that can become really ugly, especially if the alignment and suspension angles have become altered in the installation process.

Fixing Pulsation and Judder Issues

When a customer pulls in with a complaint about brake pulsation or judder, throwing parts at a repair will not solve the problem.