Summer is here. On any given weekend, you’ll find the proud owners of classic cars touring the countryside, parked at competitions, or showing off at cruise-in events. Thanks to the increasing numbers of classic car enthusiasts including Baby Boomers, this niche tire segment is growing.

While the definition of a “classic car” can vary, for the purposes of this article, consider it to be an older vehicle that is historically interesting and worthy of restoration, preservation, and care.

The two companies best known for authentic reproduction tires for classic cars are Coker Tire Co. and Kelsey Tire Inc. Others offer vintage tire designs.

For tire dealers, recommending the right tire to a classic car owner requires a deeper level of understanding about the customer, their interests, and how they plan to use the vehicle. Greg Hathcock, president of Vogue Tyre & Rubber Co., explains that it’s the intention of the customer that will determine the best tire for each unique application.

“If they’re showing the car and it actually has to be the same tire that came on the car, then they’re going to probably want to use a Coker or a Kelsey type of product, depending on the brand that came on the car,” Hathcock says. “But if that owner is going to drive the car, then you need to think about [other options].”

Wade Kawasaki, president and COO of Coker Tire, adds that if the customer wants both – a bias-ply look with a higher speed rating – some classic tire companies offer a bias-ply look radial with higher speed ratings.

“At Coker Tire, we build the original tires that went on those cars. Now, these are bias-ply tires, so they don’t ride the best, but they are the absolute factory originals. On my particular car, those are the tires that I have because this is a perfect 100-point restoration,” says Kawasaki referring to his 1970 GTO Judge with 44,000 original miles. “Now on my ’64 El Camino, I drive that a lot, but I still want the original look. So instead of a bias-ply tire, I went with a bias-ply look, but it’s actually a radial construction tire. It still has that factory ‘60s appearance, but it has modern radial construction. Of course, it doesn’t follow the [ruts] on the freeway, but it rides better and it’s a lot quieter – all the things my wife really loves about driving in a vintage car, those are the things that that has.”

To visually identify a bias-ply tire design versus a more modern radial tire, the difference between the two types of construction is more obvious at the sides and shoulder of the tire.

“A bias-ply tire or cross-ply tire, which was built in the ‘50s all the way up through ‘70s, is a tire with a harder shoulder so the sides of the tire are flatter, and the shoulder where it meets the tread is at a [sharper] 90° angle. With the radial tire, you’ll notice on any modern tire that the sidewalls are rounder, especially where the sidewall meets the tread. That’s the difference in the look,” explains Kawasaki.

The evolution of design, he says, was based on performance objectives. “The old school of thought was to get the most tread on the ground to get the best traction. Cross-ply or bias-ply construction, that was the way to do it.”

In the mid-1970s as engineers became more interested in how a tire moved across the pavement, especially at higher speed ratings, a rounder shoulder design showed better performance and handling. To achieve this in a tire’s construction, a layer of steel “belts” was introduced under the tread layer to better support the sidewall.

One of the challenges for manufacturers of classic tires is that many of the original molds were destroyed many years ago. To solve this, Kelsey and Coker create new molds from on the original drawings of the original tire designs.

While Kelsey Tire remains devoted to complete authenticity of the original OE tire design, Coker offers authentic aftermarket reproductions with modern updates as options.

“What we thoroughly enjoy is doing the research and making sure that the tire is brought back exactly the way it was,” explains John Kelsey, president of Kelsey Tire. “If it was nylon originally and nylon only, then that’s the way it is today. All of the external optics of the tire have to be exact, as well as the internal construction.”

Modern materials are used to create these new “old” tires. Some changes are made through chemistry (such as tread compounds and whitewall stock). Others are by government mandate.

“Any time there’s been an opportunity to improve or comply, that’s in the tire,” says Kelsey.

Working with Whitewalls

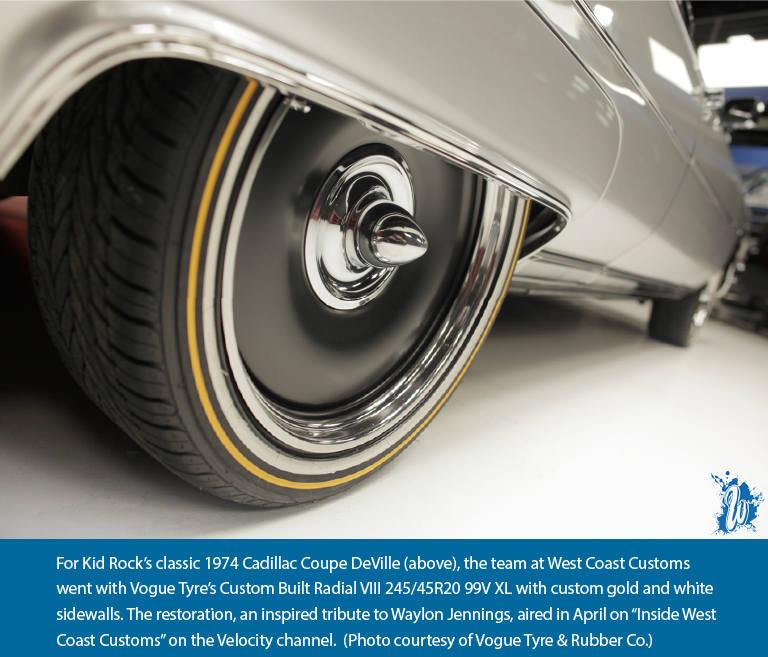

The technology to create a whitewall tire can vary. Many are constructed pre-cure using a layer of white rubber on a raised platform on the side of the tire. Once the tire has been cured and the vulcanization process is complete, buff off the outer layer of black rubber to expose a white sidewall or white raised lettering. Vogue Tyre also offers a unique process where a contrasting gold color of rubber sits protected inside a plateau on the sidewall and is then buffed to a clean stripe after the tire has been cured. Other manufacturers produce whitewalls by post-cure appliqué. In some cases they’ll “shave” the side of the tire to apply the whitewall.

Creating a whitewall is not an easy process. Fewer major manufacturers remain interested in making tires due to complexity and higher visual defects that are inherent to production.

Inside the shop, working with whitewall tires requires special consideration. Hathcock of Vogue Tyre, the company credited with inventing the whitewall tire, explains the importance of proper storage, stacking, and handling.

“In terms of storing them, you never want to put the white or colored sidewall against the black side of a tire. You want to put whitewall to whitewall for stacking them on top of each other so they don’t stain,” Hathcock says. “You’ve probably seen whitewalls come off of a truck and they have that blue protective coating on them. If you’re a tire dealer, you might want to keep some of that [protective film] on hand so you can put extra on just in case it rubbed off in the truck or something, to protect it.”

“Those whitewalls, just like every other rubber, are affected by UV,” says Kawasaki. It’s a great idea when you’re storing those tires to make sure they’re stored outside of the sun and not exposed to sunlight because the UV will affect that whitewall tire. Over a long period of time, it may become off-white, either a light tan or a light yellow ivory after years and years of operation.”

Installing Classic Tires

There’s really nothing different about mounting white wall tires or classic tires from a traditional passenger tire.

“The beauty of classic tires is that they’re actually easier because they were mounted on old Coats 10/10 machines,” adds Kawasaki. “With the modern tire mounting machines, it’s a breeze.”

Brian Fjeldsted, vice president of marketing at Vogue Tyre, said balancing is less of a challenge with the more modern tire designs. “From a dealer’s standpoint, just the ease of installation of a modern tire versus what would be a traditional bias-ply tire and getting it balanced. Today’s tires are built to a much higher standard tolerance. The runout, the balancing, it should all be easier with a more modern tire versus tires that were designed and engineered in the ‘50s, ‘60s, and ‘70s,” he says.

Fulfillment rates for vintage specialty tires across manufacturers range from two to four days in most cases. According to Kelsey, because of the specific nature of each tire, it helps to check with the manufacturer as well as distributors to help source what you need.