Federal-Mogul Expands Moog Product Offerings

Federal-Mogul Expands Moog Product Offerings Federal-Mogul Motorparts has expanded its Moog line of steering and suspension parts, driveline components and wheel hub assemblies to include 42 additional parts. The additional parts allow Moog to better cover North American, Asian and European passenger vehicles, Federal-Mogul said. “More than half of the Moog parts introduced in May

Test Drive Techniques

Test drives on the surface can seem like one of the most unprofitable tasks a technician can perform. But, it can be one of the most profitable processes a shop can do to help sell more service. You just have to have procedures and training in place so a test drive is more than just

Loaded Strut Advantages

Recommending and selling loaded strut assemblies not only makes for happier, safer and more profitable technicians, it also provides the customer with the benefit of completely new components. In addition to the strut itself, a loaded strut includes the upper strut mount, strut bumper and boot, spring seat and insulators, and coil spring. Prior to

Reading Tire Wear Patterns

A tire can tell you a lot about a suspension. Most specifically, it can tell you if the angles, inflation and components are within specification. Here are the most common wear patterns and what causes them. Over-inflation Wear Tire wear in the center of the tread pattern tells you that the inflation patterns are too

Rack And Pinion Unit Repairs

When your professional alignment technician inspects a vehicle’s steering linkage, it’s very easy to spot a leaking rack and pinion steering gear because the rack boots are filled with leaking oil. Similarly, a conventional recirculating ball steering gear is usually worn out when oil is leaking from its steering shaft or sector shaft seals. An

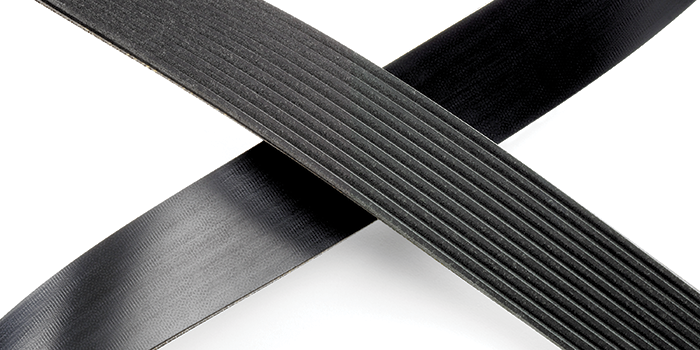

10 Tips for Serpentine Belt System Inspection and Service

1. Where is the wear? Like a tire, the friction between the belt and pulleys wears away at the belt, usually on the tops and walls of the ribs. Eventually the grooves of the pulleys will bottom out on the grooves of the belt, and then the belt will start to slip. According to one

Why Alignment Angles Change

An alignment angle doesn’t change randomly. There is a cause-and-effect relationship between external and internal forces that can alter the geometry of a vehicle’s suspension. Having the alignment reading for only one angle on one corner is just like having the outside temperature without knowing if there is a tornado outside. Just making an adjustment

It’s a Noisy World

Know that all brakes make noise. When the friction material makes contact with the rotor, the coupling causes the brake pad and rotor to oscillate and vibrate. The components are locked as a combined system that will vibrate at its natural frequency, called “force-coupled excitation.” The driver hears this excitation as noise. The amount of

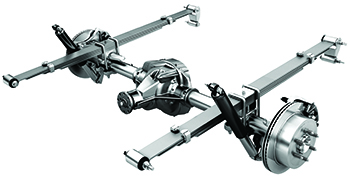

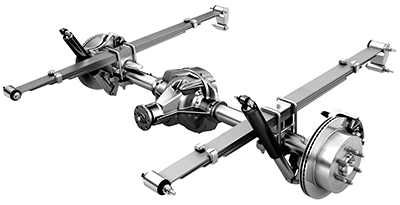

Solid/Live Axle Diagnostics

In 1963, almost every car manufactured in the U.S. had a solid rear axle. There were exceptions like the Corvette and Corvair. Today, pickup trucks and only a few light- to medium-duty SUVs/passenger vehicles still use solid rear axles. It’s not uncommon for a solid rear axle vehicle to go its entire life on one

Solid/Live Axle Diagnostics

In 1963, almost every car manufactured in the U.S. had a solid rear axle. There were exceptions like the Corvette and Corvair. Today, pickup trucks and only a few light- to medium-duty SUVs/passenger vehicles still use solid rear axles. It’s not uncommon for a solid rear axle vehicle to go its entire life on one