Trucking and logistics companies know that tires represent a big chunk of their marginal costs. On average, the marginal cost of tires is $0.038 a mile or $1.50 an hour, according to the American Transportation Research Institute. And that’s no surprise: an 18-wheeler packs 18 tires that cost an average of $375 each – that’s $6,750 per truck! So when it comes to optimizing operation costs and revenue, keeping tires under your radar seems obvious.

Maintaining commercial tires correctly not only increases their potential mileage but also helps reduce fuel consumption. That’s why fleet managers need to keep a close eye on key data points – such as the tire pressure, tread depth, rotation and balancing of their tires, just to name a few. But if that sounds easy for a single truck, the task becomes overwhelming for a fleet of ten, a hundred or a thousand vehicles.

Why is digitally tracking tire data so important?

When you need to manage hundreds or thousands of tires within a commercial fleet, tracking each tire individually requires perfect data recording. Each tire has a Tire Identification Number (TIN) or DOT code molded on its sidewall. This TIN can be used to identify each tire actively equipped in your fleet or in storage, and that allows a better follow-up of the maintenance of each tire. In some countries, an additional commercial tire serial number is also added.

But that’s where the problems occur. A single incorrect TIN/DOT record in your tire management system will directly affect the maintenance processes and will slow down progress towards reducing your cost-per-mile. Here are some specific issues that can arise from incorrect data recording:

- When maintenance activities are not properly linked to the right tire, it will be impossible to know what previous work has been done on them in the future.

- This means that maintenance activities are repeated, wasting valuable mechanic time and effort.

- If the serial number is incorrectly recorded, it could accidentally match another active tire, creating a hazard for the truck and driver due to a lack of maintenance.

Tire data also provides additional benefits to fleet managers.

With rising prices and the difficulty of differentiating one tire from another, commercial tires are increasingly targeted by bad actors. Around the world, the theft of truck and trailer tires is on the rise, with many trucking companies finding that their high-end tires have been swapped for cheap or older tires after a long trip.

By recording the TIN/DOT and other tire data, fleet managers have the information at hand to prove if their tires have been stolen. Here’s how it works:

- Managers can record the tire data on trucks when they are mounted, then quickly check them when they return from a trip. If the tire data does not match, you can easily identify if you have been the victim of theft.

- With the accurate digital records of your tire data, the police will have a better chance of identifying and recovering the stolen tires

Digitally recording the TIN/DOT of each of your tires also helps keep drivers safe on the road.

The older tires get, the more hazardous they become. Some European countries have even imposed a ban on old tires for commercial vehicles. The TIN/DOT code contains the date of manufacture of each tire, giving you the age of each tire, so you can replace older ones in good time.

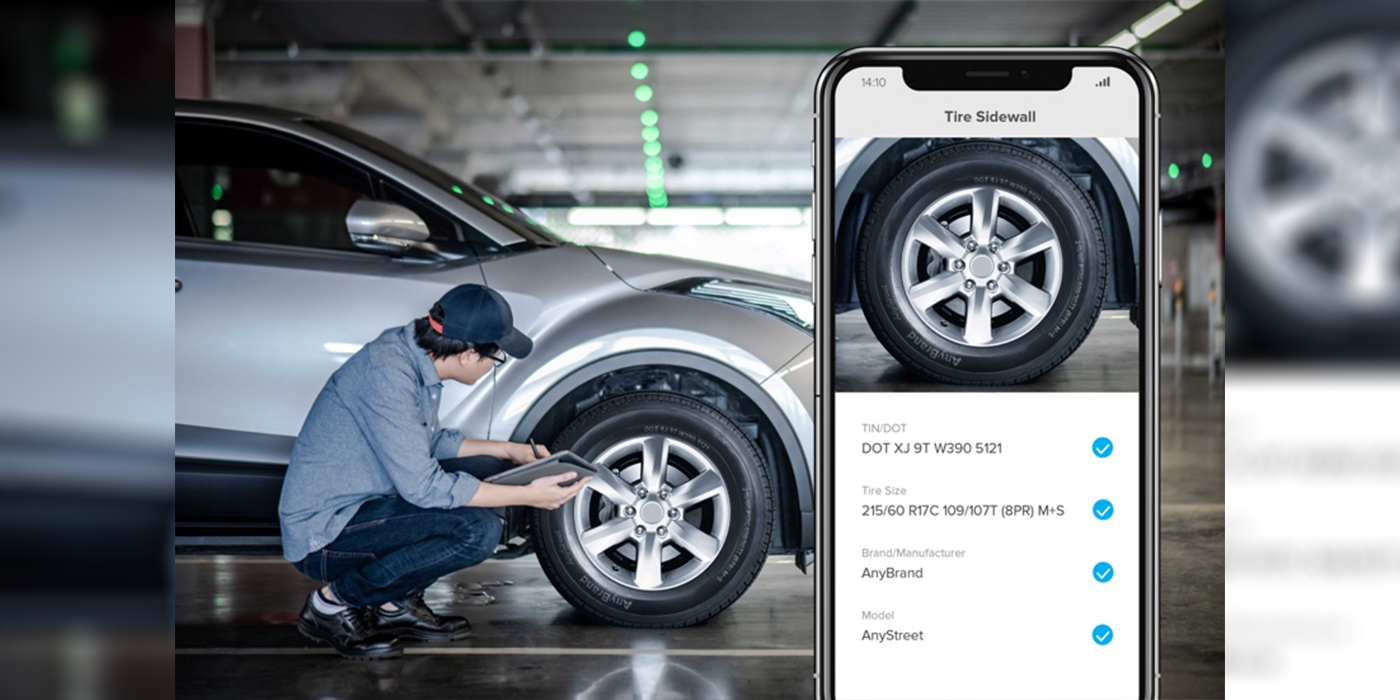

A simple scan takes the pain out of tire data collection.

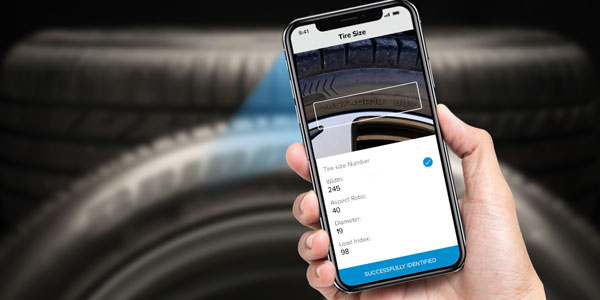

If you think that collecting the TIN/DOT and other data off tire sidewalls needs to be done manually – fear not! Today, digital tools exist that collect the data you need instantly and accurately. With OCR technology, fleet owners can track TIN/DOT using any smartphone or any device equipped with a camera – even TPMS devices. By simply scanning the sidewall of the tire, you will instantly record the DOT in your management or inventory system. OCR is a simple, fast and accurate solution to keep track of your tires and work on operation costs optimization.

Put into practice, digital tire data collection empowers trucking companies and fleet managers to manage their tire inventories at scale, optimize operational costs, and have fully visibility of their tires at every stage.

Sponsored by Anyline