When shocks and struts wear out, there are almost no visual clues. When a unit is leaking, it is a sign of failure and not wear.  Next to performing an autopsy or throwing the unit on a dynamometer, there is no conclusive way to determine if the internal components are worn to a point where it could compromise vehicle stability. Even the “knee on the bumper” test can give false results due to how some units handle low frequency movements.

Next to performing an autopsy or throwing the unit on a dynamometer, there is no conclusive way to determine if the internal components are worn to a point where it could compromise vehicle stability. Even the “knee on the bumper” test can give false results due to how some units handle low frequency movements.

Shocks and struts wear, and their performance degrades, gradually and even imperceptibly. After more than three years of durability testing, the Automotive Maintenance and Repair Association (AMRA) says the answer is 50,000 miles. AMRA represents the automotive repair industry and promotes a consumer outreach effort, the Motorist Assurance Program (MAP), which is meant to strengthen communication and trust between the industry and its customers. MAP has expanded its Uniform Inspection & Communication Standards (UICS) to include a standard for shocks and struts. The standard says most ride control units degrade measurably by 50,000 miles and replacement for improved vehicle performance may be suggested to the customer after that point.

This standard is for OEM hydraulic fluid and/or gas charged shocks and struts only, not for electronically controlled units.

This replacement recommendation was determined through more than three years of testing performed by four major manufacturers of shocks and struts. In laboratory testing, shocks and struts were tested more than 70 million cycles of compression and rebound.

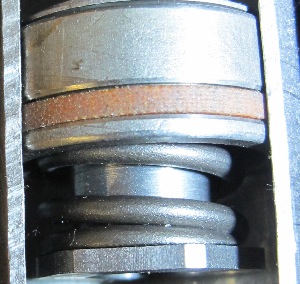

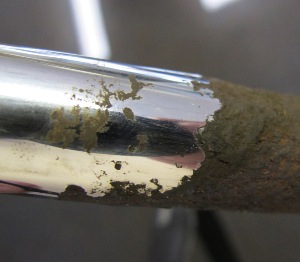

The wear incurred during the 70 million cycles was not on the outside, but on the inside. A look at the photos shown here will show where the wear occurs.