This year marks the 20th anniversary of Goodyear’s Aquatred, considered to be the industry’s breakthrough rain tire.

After decades of industry attempts, that tire’s introduction finally elevated the importance of a tread pattern’s contribution to wet traction performance with its aqua channel design and accompanying water pump action.

Rubber compound advancements have emerged alongside ongoing tread pattern refinements to further enhance the company’s family of wet traction tires, according to Bob Toth, Goodyear’s director of new products for North America.

“We’re constantly working on tires’ wet traction enhancements, balancing the improvements with ice, dry pavement and cornering performance,” says Toth, a 35-year Goodyear veteran. “We also have stayed focused on extended tread life and reduced rolling resistance. High density silica in tread compounds has become a common component to help achieve performance goals.”

Continental Tire the Americas’ Alessandra Ferraris, director of research and development, says wet pavement grip has been improved by innovations in polymer technology and new silica types. Many compounding and processing measures made small contributions that have added up to major improvements over the years, according to Ferraris.

Ferraris, who has been with Continental for 11 years, says high-tech silica technology combined with appropriate synthetic polymer blends has advanced material technology.

She says there are many different types of silica, but the type used to clean and whiten people’s teeth would not perform well in tires. “Tire silicas are specialized, with new ones being introduced annually to improve wet grip when used with various polymer blends, resin technology, silanes and reactive chemistry.”

To be clear, all tires in highway service have wet traction characteristics for safety. Some have more than others.

Dan Guiney, Yokohama Tire Corp.’s director of technical services, says wet pavement traction – like all other types of traction – is dependent on tire contact with road surfaces. “It’s the interaction created at the point of contact – the footprint,” he says. “The effectiveness of a tire’s grip depends on the quality and frequency or rate of interactions taking place. A vehicle’s speed, amount of water on the roadway and time available to evacuate it impact a tire’s ability to interact with the surface.”

According to Guiney, who joined the company in 2002 and has been a tire engineer for 39 years, the challenge is simple to understand: move water away from a tire’s footprint and let the rubber compounds go to work on a road’s surface texture.

Once contact with the surface is made, a tire interacts with a roadway’s macro- and micro-textures, says Guiney. Macro-texture is a highway surface’s stones and aggregate, along with binder material. There may be 20 to 30 stones per square foot of paving, providing a small amount of contact area and low-frequency grip opportunity. Micro-texture is found at the microscopic level and provides more contact at a much higher frequency rate.

Ferraris says the optimization of pressure distribution from tire construction and profile plays a key role in wet traction. A tire’s construction has a direct relationship with tire footprint management that affects its shape and contact pressure distribution.

The real magic happens at the point of contact, says Guiney, where nano-compounds create a relationship between tire materials and the road’s micro-texture. For example, the Yokohama dB Super E-spec tire utilizes orange oil boasting a similar molecular architecture to natural rubber. The orange-peel extract properties generate heat during the tire’s active mode to deliver better grip vital to wet surface performance.

“Emulsion polymers were the foundation of past tire compound development,” says Ferraris, “but solution polymers are the present and future.”

She says emulsion polymers are partially branched polymers that have free, unused ends in a polymer network. “The loose ends make the polymer unable to efficiently network to other portions of a compound, wasting a chance for stronger bonds.”

Solution polymers, she explains, are linear and “offer the opportunity to be modified by chemical functions to have better networks and interaction to fillers and chemicals within the compound.”

She says there’s still a place for emulsion polymers in the tire industry, including off-road and heavy-load applications, but “solution polymers provide passenger tires with technologically-advanced wet traction compounding, coupled with lower rolling resistance and improved mileage.”

Footprint size also is important. “Driver’s don’t want a surfboard effect from their tires,” says Guiney. “To plow through a wave of water, a wide, short tire footprint is more challenging than a long and narrow one. Low aspect ratios are designed for the highest dry-grip performance, but they still have to be ready to perform on wet surfaces.”

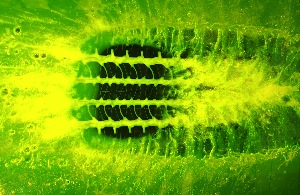

Tread patterns are designed to move water away from the footprint to prevent hydroplaning. Circumferential grooves channel or pump away massive quantities of water. Then, the tread sipes take over, where more can be good.

Tread in Action

So, what happens as a tire changes direction or speed on a highway? Goodyear’s Toth says a tire’s tread pattern is relatively constant on straight stretches, but when subjected to different loads and forces resulting from cornering, accelerating and braking, the contact patch’s shape, size and orientation change dramatically. “Our tires are designed to optimize an effective contact patch size, shape and orientation when subjected to these dynamics.”

Guiney adds that it’s all about frequency changes. “Going straight down a road, a tire is fully engaged with the surface micro-texture, but cornering and braking change contact frequency while the inherent energy changes direction. As the frequency of tire-to-road interaction escalates, energy distribution and accompanying heat increase. Tire compounds must react to these changes.”

Tire dealers have the opportunity to educate customers about tread wear and wet traction performance, says Guiney. “We know a loss of tread depth equates to a reduced ability to handle the optimum amount of water. Tires are developed and tested with this in mind and can be safely operated to their 2/32nds tread depth, but as tread wears away, a tire can’t vacate as much water. Drivers must adjust their expectations as tires wear out and watch out for heavy rains and driving too fast for the conditions.”

Continental has developed a way for consumers to determine how tread wear affects their tires’ performance. Tuned Performance Indicators, or TPI, indicate a tire’s ability to perform in dry and wet conditions. For example, the Continental ExtremeContact performance tire’s “DW” branding on its tread face indicates the tire is optimally tuned for dry (D) and wet (W) conditions. Through use, the “W” will wear away, indicating that the tire is no longer tuned for optimum wet traction performance. The same goes for the “D.”

Toth says Goodyear research indicates wet traction is consistently important to tire shoppers. “Dealers should help them understand that a tire’s tread pattern and compounding are important to ensure wet traction, but tread depth is also critical,” he says. “Therefore, consumers also should inspect tires frequently to ensure adequate tread depth exists.”

Ferraris says wet traction is probably the most difficult characteristic for a consumer to judge at a tire store. “They can compare tread patterns, price and wear warranties, but need help to understand how a tire’s performance characteristics affect the overall safety of a driver and passengers.”