Commercial tire dealers need to understand the issues associated with the variations and fluctuations in tire pressure based on the many variables that affect tires on a day-to-day basis. Trucking fleets typically get caught up in why there are tire pressure variations during routine inspections – and it’s up to dealers to offer simple explanations.

With tire prices continuing to climb, the investment by fleets in both new and retread tires is significant. Every fleet is trying to maximize fuel economy, treadwear and retreadability. Inflation pressure plays a major role in how tires perform.

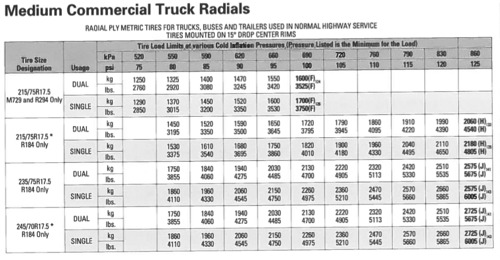

Every fleet should determine its recommended inflation pressure based on the worst vehicle load. Since loads vary by wheel position, using the load/inflation tables published by any tire manufacturer will determine the proper tire pressure based on a specific load. This is why many fleets have a different inflation pressure specification for steer vs. drive vs. trailer tires.

Those load/inflation tables, which all are based on an ambient temperature of 70F, can be confusing if you do not use them on a regular basis. Choose the correct tire size and then move over to the column with the tire load measured in pounds. The pressure is listed for that individual tire load (See chart).

During a tire pressure survey on a specific tractor-trailer, individual inflation pressure levels can have quite a spread. Steer tires are most often closest to the fleet specification. Drivers check the two steer tires on a regular basis since they are easy to check and they affect vehicle performance – truck drivers want nothing to do with an underinflated steer tire.

Drive tires are not checked as frequently as steer tires, especially inside duals, which require much more effort by the driver. Bending, getting dirty and reaching an arm inside the hand holes all require time and discourage the driver from checking those tires regularly.

Trailer tires are another story – they are the most neglected and cause the most issues. Inside dual trailer tires are always the lowest on the tire pressure surveys. The high amount of irregular wear found on trailer tires can be traced back to underinflation. Most of the rubber found on the side of the roads and on the highway are the remains of tires that ran underinflated for a long time, generated excessive heat and finally got destroyed.

Real-World Example

You check a tire at 8 a.m. and the shop temperature is 70F. The load/inflation table shows that you should be running 100 psi on a 295/75R22.5 LR G steer tire based on the worst-case load of 5,780 pounds/tire. Using a calibrated pressure gauge, you measure exactly 100 psi. The fully-loaded tractor-trailer leaves the yard and begins running on the interstate at 65 mph. Within five minutes, the driver leaves his cab and checks that same steer tire and finds 107 psi. He gets back on the road and drives an additional 20 minutes and rechecks the same steer tire and measures 115 psi. Thirty minutes later, the tire pressure is still 115 psi, while the outside temperature has not risen from the 70F.

Time for a five-minute coffee break. The driver stops the vehicle, finishes his coffee, and finds the tire pressure is now up to 118 psi. Why? The sun is shining brightly, causing the increase in tire pressure.

The driver now gets back on the highway and runs for another hour before checking the tire pressure again – it’s still 118 psi. The tire has reached a steady state condition and will stay at this pressure assuming all operating conditions remain the same, including the outside temperature. But, of course, that is not going to happen.

The road surface will have an impact on the tire pressure, as well. For instance, consider the difference between running on concrete and asphalt. The surface temperature of asphalt is usually hotter than concrete and may increase the tire pressure another 1 or 2 psi. Due to this, the tire pressure now may reach 120 psi. Vehicle speed can increase the tire pressure even further. Running at 75 mph vs. 65 mph will generate more heat and the tire pressure may reach 125 psi.

Should you be concerned that the tire is 25% “overinflated” at 125 psi? The answer is simple: NO! All of these load, speed and temperature variables are taken into account when a commercial radial truck tire is designed, developed and tested. Welcome to the real world. This is why tire companies clearly state in their literature to never check a hot tire for pressure because you will think that the tire is overinflated when it is exactly where it should be.

And don’t take air out of a hot tire! A truck tire can take several hours to revert back to its original inflation pressure, and you simply do not know where in the cycle you are at the time you check the pressure. It is recommended to check your tire pressures first thing in the morning after the tire has cooled down overnight.

Weather’s Effects

However, cold weather can create a different challenge. As an example, a tire that has cooled down after running all day and measures 100 psi at 70F will lose pressure if it sits out overnight and the temperature drops to 20F. When the tire is checked, you might find only 90 psi in the tire because when the temperature drops, so does the tire pressure. Every loss of 10F equals a loss of 2 psi. You may think that the tire is underinflated, but it is not. As soon as it warms back up to 70F, the inflation pressure will be back to the specified 100 psi.

We always say that heat is a tire’s worst enemy, and that is true when a tire running underinflated generates excessive internal heat due to the increased sidewall flexing and longer tire footprint (more rubber on the road).

An underinflated tire is always much more serious than a tire being overinflated by a few psi. Excessive heat eventually will lead to tire failure.

Finally, keep in mind there can be a large discrepancy between tire pressure gauges. The most common stick type gauges are only +/- 3% accurate when they are brand-new. Dropping them on the hard concrete may cause the stick readout to no longer align properly with the internal spring. This can change the pressure readout even further. And, of course, the spring properties change based on temperature. If it is cold outside, the spring stiffness increases. During the summer season, the spring stiffness decreases.

It’s a good habit to check tire pressure gauges against a master gauge on a regular basis if you want accurate tire pressure survey results. Master gauges can be purchased from any tire supply company.