We all know trailers that are misaligned and out of spec will lead to early tire removals, a decrease in vehicle fuel economy and many unhappy drivers.

Today’s trucking fleets are looking at every possible way to improve fuel economy and maximize tire performance. When it comes to their maintenance budget, trailer alignment and trailer tires are typically last on a fleet’s priority list. This is a big opportunity for commercial tire dealers to work with their customers’ trailers and help improve tire removal miles through proper alignment.

Did you hear about the study that finds you no longer have to change oil in your engines? You just change engines more often. The same analogy holds for vehicle alignment. You don’t need to check alignment, simply buy more tires and fuel.

The Technology Maintenance Council (TMC) publishes the bible of the industry when it comes to tire conditions: Radial Tire Conditions Analysis Guide (volume 4). This 164-page, full-color book is a comprehensive review of tread wear and tire conditions, and the causes of irregular wear.

There are specifically two trailer tire wear conditions directly related to trailer misalignment: one-sided wear and rapid shoulder wear on one side of the tire.

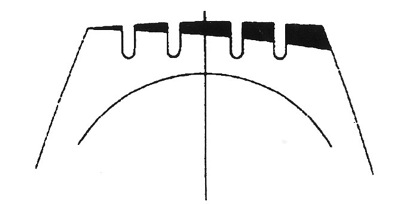

One-sided wear is defined as excessive wear across the entire tread surface where the fastest wear is on the outside or inside shoulder rib and each of the adjacent ribs also are worn, but to a lesser extent. Excessive toe is the major cause for this tire condition.

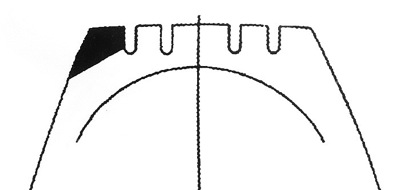

Rapid shoulder wear on one side of the tire is the other condition related to trailer misalignment. Excessive camber and a misaligned or bent axle will lead to this rapid shoulder wear condition.

Trailer tires have a history of neglect and underinflation. Tires underinflated against fleet specification will magnify these irregular wear alignment-related conditions and lead to even earlier removal miles and reduced overall fuel economy.

This past April, TMC issued a Recommended Practice on trailer alignment – RP 708B – which details the procedure on how to quickly and easily measure trailer alignment. Axle toe also is included in this document, since toe is the alignment setting that affects tire wear the greatest.

Very little equipment investment is required by a commercial tire dealer to check a trailer for alignment. A trammel bar, tape measure, kingpin extender and wheel-end extender are all that is required.

Once you have the required tools, it’s time to measure the trailer alignment. This procedure involves several steps:

• Properly position the trailer

• Set the designed kingpin height

• Check the initial axle alignment

Select the appropriate alignment area. This area should be flat, level and debris-free. You most definitely want to inspect the tires to ensure each dual wheel set is within 3/4-inch in circumference. New tires mixed in with worn tires will lead to unreliable data. All tires should be set to the same pressure.

The next alignment preparation step is to make sure you set the suspension ride height to the designed ride height, which should be listed on a vehicle placard. If not listed, contact the manufacturer for this height setting.

The last pre-alignment check is to inspect the trailer and suspension for any damaged components.

Alignment Procedure

The actual trailer alignment procedure begins with proper positioning of the trailer. The trailer suspension must be in a “relaxed” state without any pre-load applied to the bushings. There are several ways to ensure there is no pre-load, depending on whether the trailer has a slider or non-slider.

For example, if the trailer is a non-slider, adjust the trailer landing legs so there is adequate ground clearance while the trailer is still coupled to the tractor. Then pull the trailer forward a minimum of 10 feet and gently apply the trailer service brakes. Now lower the trailer landing legs. Uncouple the trailer. Keep the trailer parking brakes disengaged.

Now it is time to set the front of the trailer to its designed kingpin height. This designed height should be listed on the trailer ID tag. Use a tape measure to determine the kingpin height by measuring from the ground to the kingpin mounting plate. Adjust the trailer landing legs to the designed kingpin height.

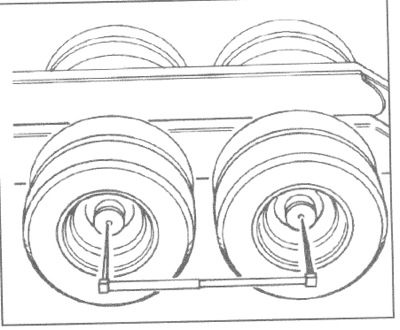

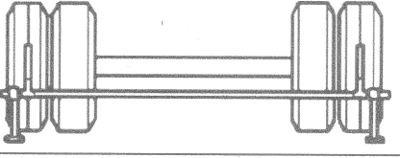

Check the initial axle alignment by using a kingpin extender or adapter, along with installing a wheel-end extender. Make sure the wheel-end extenders are a matched pair.

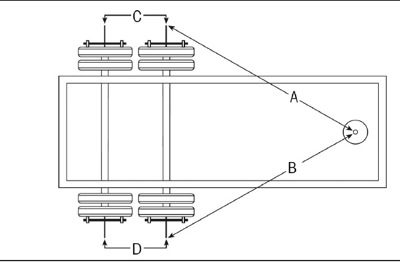

Next, measure the length of the wheel-end extender and the axle track length. Using a tape measure, there are four additional measurements required. You need to measure the distance from the kingpin to the end of the wheel extender of the front axle for both sides of the trailer (A & B). You also need to measure the length between the center point of the two outside tires on each side of the trailer (C & D).

Depending on the wheel-end extender length and the width of the axle track, the front axle target length (A & B measurement) is either +/- 3/16-inch or +/- 7/32-inch.

If the difference between the A and B measurements is smaller than or equal to the target value, the axle is within specification and no adjustment is required.

The distance between axles – from the center of one hub to the other hub center – is the C and D measurement. Use a trammel bar to measure these values. Position the trammel bar so the pointers are at the center of the front- and rear-axle spindles. These measurements should be within 1/16-inch. If they differ by more, adjust the rear axle position.

The last important measurement is axle toe, which has a significant effect on alignment. Use a trammel bar to mark the tire centerline with chalk on both outside tires on the front axle. Remove the trammel bar and move the trailer backwards so the tires rotate one-half turn. Using the same trammel bar, but now from the backside of the front axle, scribe a new chalk line as before. If the toe is 0, the second line marked will be superimposed on the first line.

If the two scribed lines are not superimposed, the distance between them is the amount of toe-in or toe-out. If an axle has excessive toe, it is impossible to align the axle so that acceptable tire wear is obtained. Excessive toe usually is due to a spindle bent from an impact. The only way to adjust toe on a trailer is to bend the axle, which is not recommended by trailer axle manufacturers.

With a little practice and the right tools, you quickly can measure trailer alignment and help your customers optimize tire wear and fuel economy by ensuring their vehicles are rolling down the highway in a straight line.