Eventually, it comes time for hardworking farm tires to be replaced. Most of the time, the need for replacement can be determined during maintenance checks.

Matt Frank, senior product brand manager for Bridgestone Americas’ Firestone Agriculture Tires, says when tread depth decreases below 20% of its original depth, new tires may be needed. In addition, under-inflated or over-deflected tires can cause damage to the body plies, making the tire unusable.

He adds that ag tires are exposed to many objects and conditions that can create cuts and tears in the exterior rubber. If these cuts or tears go deep enough to expose the body plies or belts, the tire needs to be replaced.

Blaine Cox, national product manager of agriculture and turf for Yokohama Off-Highway Tires America, says that if a sidewall is bulging from impact damage, the casing is compromised and the tire needs to be replaced by a professional who can deflate it safely in a cage.

Regarding tread wear, he says that replacing a farm tire is a little bit like inflating one — there’s a good deal to consider.

“For instance, with a chore tractor that’s just running around the yard carrying hay or scraping roads, you can probably operate with a pretty worn set of tires,” Cox says. “But if we’re talking about a tractor that the farmer uses for fieldwork or planting, you’re going to want to be more proactive.”

He says the most scientific way to look at it is to watch the slip indicator in the cab. If the tire is properly inflated and ballasted and you’re still seeing more than about 10% or 15% slip, the tread is probably too worn and the farmer is wasting fuel and horsepower. With high diesel prices, replacing those tires can pay off fairly quickly.

“If the farmer doesn’t have a slip monitor or we’re talking about a towed implement, I tell farmers to get out and look at the tire tracks they just made,” Cox says. “If the impressions of the lugs are sharp and clear, they’re not slipping much. If the tracks are fuzzy-looking or you can see piles of dirt toward the rear that have been kicked up, that’s more slip than you want.”

The Right Replacement

To earn and keep customers’ trust, ag tire dealers must be knowledgeable in recommending the right replacement tires. There are a multitude of factors to consider, including the type of equipment, the soil conditions and the applications in which the equipment will be used.

Scott Sloan, ag product manager for Titan International, says dealers can help customers determine the weighted load of the tractor and any potential fluctuations throughout the season in order to recommend the right tire.

“They should also be up-to-date on the newest technology and research around farm tires,” he adds. “For example, it used to be assumed that standard dual tires worked well in every application. But we now know that unless a farmer is running a tractor between rows post-emergence, super single tires are likely the best choice and will help them avoid unnecessary pinch row compaction.”

BKT’s Dave Paulk, manager of field technical services, says that on mechanical front-wheel drive tractors, the right size tires should be used to ensure that the lead/lag requirements are met.

“The 45-degree tread pattern works well on the road and in the field,” he says. “The most important consideration is using tires with the correct load indexes and speed ratings for the tractor and the application. IF and VF tires have higher load carrying capacities and may be needed over standard tires in some applications.”

Frank advises that when replacing only the front or rear tires, compared to all four tires, it is critical to maintain the machine’s proper gear ratio, especially to help avoid costly transmission repairs. Farmers also should recognize that there is a maximum speed the tires can handle.

Additionally, there are two different types of tire construction: bias-ply and radial. According to Frank, both tires can provide function and value based on individual application needs.

“Bias-ply tires are durable and more cost-effective,” he says. “Radial tires are more expensive, but also more efficient and longer-lasting. They have a wider footprint and disperse the machine’s weight or load over a larger area, helping to reduce soil compaction and ruts while providing increased traction and grip. While some specific agricultural needs and equipment may call for the lower-cost bias-ply option, Firestone Ag recommends radial tires in nearly all cases, given their long life, smoother ride and better outcomes.”

Because tractors drastically differ from one another, and not every tire will fit each specific model. Frank says farmers must understand the type of tractor they own. It’s also important to identify whether the tractor has two-wheel or four-wheel drive.

“Two-wheel drive tractors need front tires that aid in steering, so tires with tread patterns that encourage control are recommended,” he says. “With four-wheel drive tractors, farmers will often want to match the front and rear tires.”

Lastly, Frank advises dealers to consider terrain and traction when replacing tires.

“Of the four tire types to consider – R-1, R-2, R-3 and R-4 – most tractor owners can make good use of R-1 and R-3 tires,” he says. “Still, if they operate on wet or hard ground, they may want to consider R-2 or R-4.”

Frank recommends farmers and dealers consider terrain and traction when choosing between the four tire types:

- R-1, or agriculture tires, are likely the most common tractor tires. These are great for farming dry ground and perform well in dirt, fields and mud.

- R-2 tires have the deepest treads and are ideal for users who constantly work on wet land.

- R-3 tires, commonly known as turf tires, are frequently used for grass and can also handle loose gravel and sand.

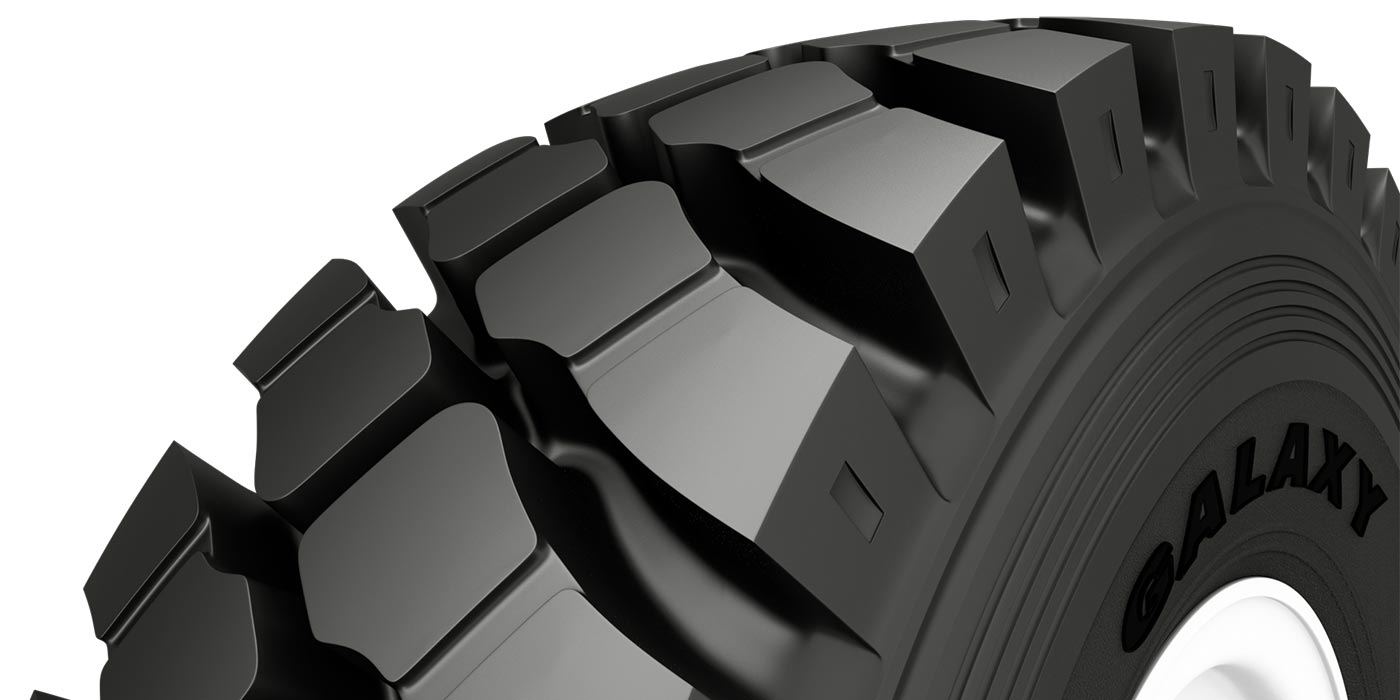

- R-4 tires, or road tires, are best for tough ground applications, such as construction and industrial work.

Looking for more on ag tires? Click here to read about the Ins and Outs of Ag Tire Maintenance.