Any spring, whether it’s a leaf, torsion or coil spring, must compensate for irregularities in the road surface, maintain the suspension system at a predetermined height and support added weight without excessive sagging.

Each of those functions is extremely important in providing comfort, precise handling and load-bearing capability in the modern vehicle – three key areas that will raise customer concerns.

Historically speaking, the steel multi-leaf spring is one of the oldest and most widely used spring designs in suspension systems. The advantages of the leaf spring are many, not only because it acts as a spring, but also because it attaches the axle directly to the chassis.

In some applications, a single “mono-leaf” spring is employed. Although leaf springs are normally used in truck applications with solid drive axles, a transverse leaf spring can be combined with an independently suspended rear axle to form a lightweight rear suspension system in performance road cars.

The leaf spring can also be tuned to different load-bearing and ride control requirements by changing the numbers, widths, thicknesses and lengths of the spring leaves.

In addition, a leaf spring tends to act as its own rebound dampener due to the friction of the leaves rubbing together. In some cases, a conventional steel spring can be replaced with a plastic unit that substantially reduces unsprung weight and resists corrosion from road salt and other elements.

Torsion Springs

Torsion-bar suspensions have been used for many years on vehicles equipped with short-long-arm (SLA) suspension systems. As the name implies, the torsion bar is simply a round bar, approximately four feet long, that’s designed to twist as weight is applied to the suspension system. Because a torsion bar is generally preloaded by a clockwise or counterclockwise twist built into it, a torsion bar will fit only the side of the vehicle for which it was designed.

The advantages of the torsion bar suspension system include compactness and light weight. Since the torsion bar tension is controlled by a threaded screw adjustment, torsion bars can be used to fine-tune suspension height. In addition, torsion bars can be attached to either the upper or lower control arms, increasing the versatility of the design.

Coil Spring

The function of a coil spring can be better understood if we visualize it as a long, thin, torsion bar wound into a coil shape. Because the coiled wire twists during the spring’s compression/extension cycles, the coil spring actually operates on the same principle as a torsion bar.

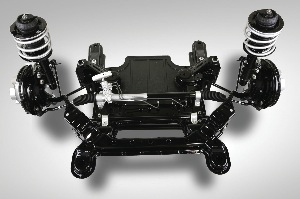

Since a coil spring occupies a relatively small space, it can be used in a variety of suspension designs including MacPherson strut, solid axle with trailing arms, independently sprung rear axle, or any SLA suspension system using a spring or coil-over shock absorber configuration.

Most modern imports use the coil spring in variations of the MacPherson strut design. In general, wire gauge, length, overall diameter and numbers of coils determine the characteristics of the coil spring.

In some cases, a coil spring can be designed as a variable rate spring that increases load-bearing capability as it’s compressed. Variable rate coil springs are often used in chassis configurations that occasionally carry heavy loads.

How Springs Work

Springs cushion the ride of a vehicle according to the principle of sprung-to-unsprung weight ratios. A farm wagon with no springs represents 100% unsprung weight. In this example, if springs are installed between the chassis and axles, the sprung-to-unsprung ratio might be 90% representing the chassis weight and 10% representing the axle and wheel weight.

As a vehicle gains speed, the springs begin to absorb the impact of striking irregularities in the road surface. As vehicle speed increases, a stiffer spring rate is required to keep the axles and wheels in contact with the road surface. This is why high-performance vehicles tend to use stiffer suspension systems than regular passenger vehicles.

Because a compressed spring will extend in a violent fashion, shock absorbers must be used to dampen the spring’s compression and extension cycles. Without dampening, a spring’s violent compression and extension would cause a vehicle to lose control on a rough road surface.

As rebound control deteriorates due to normal shock absorber wear, the vehicle will begin to experience poor ride, steering response and handling control. In addition, tire wear will be accelerated due to tire scuff caused by the suspension geometry operating out of its normal range. This is why shock/strut manufacturers are adamant about the regular inspection and replacement of worn units.

In general, the compression and extension characteristics of the shock absorber must match the compression and extension characteristics of the spring. Since stiffer springs don’t normally experience extreme ranges of travel, less dampening or rebound control might be required for normal driving. Softer-rated springs, on the other hand, may require more dampening because they tend to experience more compression and extension and, thus, make the shock absorber work much harder.

For performance applications, it’s essential to remember that the sway bar must also be included as part of any spring or shock absorber package. In any modification procedure, spring rate, shock absorber dampening and sway bar capacity must be matched to vehicle weight, chassis design and driving conditions for maximum handling, load-bearing capability and driving comfort.

Suspension Geometry

After numerous extension and compression cycles, the spring eventually experiences metal fatigue. In many cases, the spring’s original height is reduced, causing the suspension system to sag. In extreme cases of metal fatigue, the spring breaks and causes a noticeable loss of suspension height.

Sagging springs increase the camber angle of a typical SLA suspension system. In contrast, sagging springs decrease the camber angle on MacPherson strut-style suspension systems. Although most suspension systems can be adjusted to compensate for minor reductions in suspension height caused by spring sag, applications in which the camber angle isn’t adjustable might require a spring replacement to restore the suspension geometry and camber angle.

Spring Replacement

Because any compressed spring stores an explosive amount of energy – making them highly dangerous – it’s essential to use quality spring compression equipment and follow recommended safety and service procedures when replacing springs. Before removing any spring, it’s important to choreograph the procedure to make sure all the necessary tools and equipment are at hand and adjusted for use to help ensure safe spring removal and replacement.

Before replacing a spring, check for correct tire pressure and size, then record the vehicle’s suspension height at all four wheels. Replace one spring at a time to ensure that critical parts like ABS wiring and brake hoses are correctly reinstalled.

Reassembly of MacPherson struts can be aided by scribing a crayon line along the length of the strut to indicate the relationship of the parts. Before reassembly, inspect the strut support bearing for smooth operation. To prevent noisy operation, at least 1/4-inch of clearance should exist between the end of the spring coil and the spring seat stamped into the control arm or strut assembly.

When replacing torsion bars, ensure that the bars are installed in their correct positions. Correct suspension height is achieved only after a twist is worked through the bar by bouncing the suspension through 20-30 compression cycles. In some cases, the cycling process can be made easier by temporarily disconnecting the shock absorbers.

When replacing coil springs, ensure that the springs are indexed correctly from left to right and seated correctly in the spring seats located in the control arm and chassis. If the coil spring is incorrectly seated, an unwanted increase in suspension height will result. Also ensure that any rubber isolator pads or other hardware is in good condition and installed in their correct positions.

All bolts should be installed in their original locations and positions. Bolts should also be lightly lubricated with a non-friction modified lubricant, such as common motor oil, and torqued to specification. Cotter pins, self-locking nuts and interference-fit bolts should be replaced with new ones. To achieve accurate suspension height, always torque the suspension bushing pivot nuts with the full weight of the vehicle on the suspension system and at normal suspension height.

Generally speaking, the vehicle suspension height will change a small amount after driving a few thousand miles. To prevent unwanted tire wear or safety issues to arise from a new spring replacement, retorquing suspension bolts and rechecking alignment angles is a recommended operating procedure.