I’m constantly asked about placing a different tire into an application that has been running on one type of product for years. Sometimes the new approach is a good idea and making the change will cost the customer less over time. The hardest part is getting the customer to support and buy into the change. This is where the fun begins, and by working together with your customer, you can ensure a positive outcome.

Making the Switch

One example of rethinking the best tire for an application is replacing pneumatic tires with solid tires in underground mining applications. I know what you are thinking — this will never work and the ride will be terrible — but it comes with benefits.

Underground mine tires generally do not last as long depending on the operation and their maintenance practices in the mine. From my experience, the main reason for tire removals in underground operations is damage from cuts and impacts. There are much fewer tires removed due to wearing out.

What seems to happen is “out of sight, out of mind,” meaning many of the principles for managing the tires change and become more relaxed. Basically, for underground mining tires it is more important to focus on the tire maintenance. Getting another month on a tire can save the mine a lot of money annually.

Although checking air pressure is a crucial part of maintaining all tires, underground equipment is more susceptible to wheel and rim damage allowing for air loss. This is due to the conditions the equipment operates in while mining the material. The drifts are just wide enough for the machine and the corners are tight causing rim and wheel components to damage easily.

On underground equipment, side rings (flange ring) are damaged more often than any other operation. The side ring supports the bead of a tire, in return supporting the rest of the tire. When you take this support away, you are damaging a tire and more than likely it will be removed prematurely.

Because of the demands of underground mining on tires, operations use a tire fill product to address the downtime. But if a filled tire is cut, eventually the injury will get wider and the tire fill will start to break down. This will reduce the strength of the tire. The tire fill may have slowed down the removal of the tire but, in many cases, the tire will still be removed before it is worn out. So now the customer has the cost of the new tire plus the tire fill, which equates to a higher cost-per-hour.

When you mount a solid tire on the wheel and the tire is cut, the tire can continue to operate. It cannot breakdown like one with tire fill and the operator can continue to move product.

This sounds great, but your next question from the customer will be about the ride.

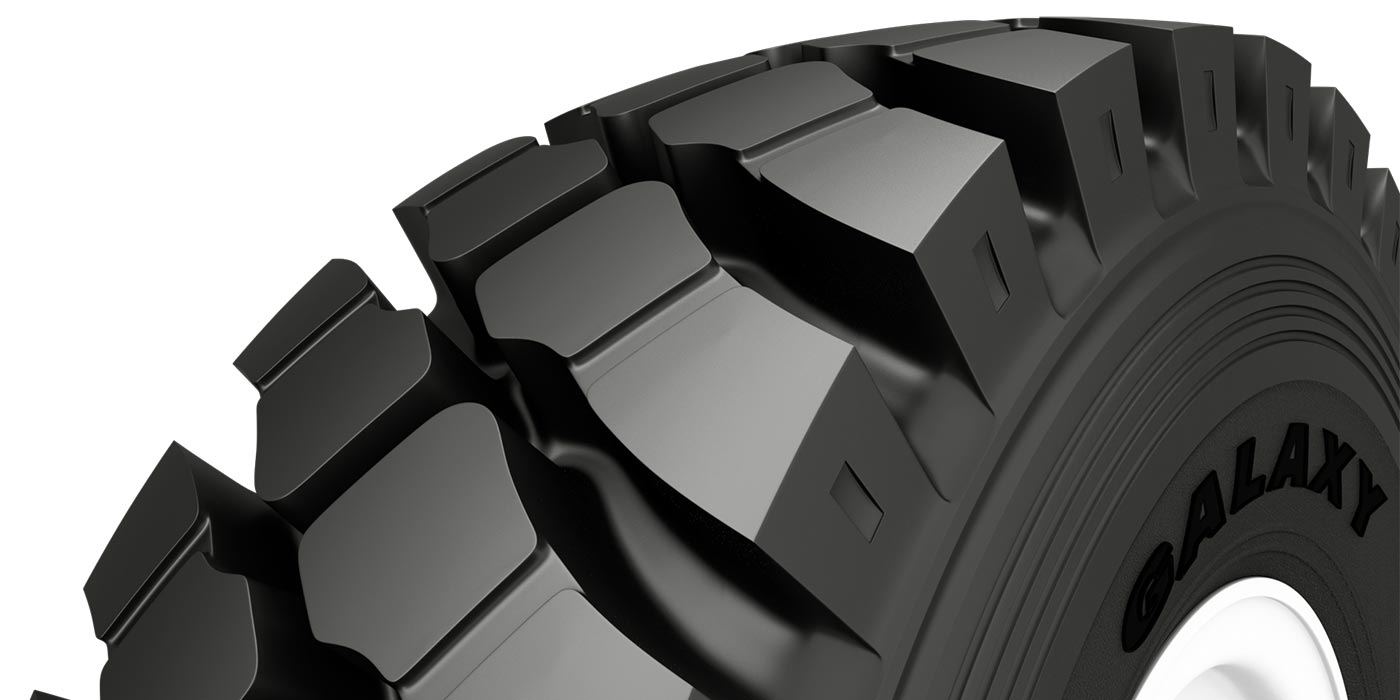

There are two options that exist today for a solid tire: a 2-stage friction base tire, and a 3-stage all-rubber tire.

A 3-stage all-rubber tire will produce a much softer ride than a 2-stage. This is due to the middle rubber compound being a lower durometer rubber, which means a more flexible rubber compound. The softer compound provides a ride closer to a tire that is filled.

The 2-stage solid tire, on the other hand, is a very rigid tire that really does not flex so the impact carries up to the operator.

Not all sizes are produced in a solid tire to cover all the wheel positions in an underground application, but if you look into what some of the manufactures have available in a 3-stage product you will be surprised.

To swap out the tire, all you will need to do is press off the old tire and on with the new. This saves time in labor as the filling process no longer needs to be done.

The up-front cost of a solid tire is more than a regular tire, but by the time you add in the cost of the tire fill and labor, you will find the cost to be much less.

Placement

What are the restrictions as to where you can place a solid a tire? You are thinking heat could be an issue. Where you currently are placing a pneumatic tire running on a scoop, shuttle car, roof bolter, etc., you can place a 3-stage solid tire. The lower durometer rubber in the middle part of the tire helps to dissipate the heat out of the tire. However, if the equipment is operated above the normal conditions, one can always have an issue with a tire no matter what is placed on the equipment.

Fitting solid tires onto the equipment isn’t just for smaller tire sizes. You can place a solid OTR tire onto the scoops running the larger 25-inch sizes, such as 26.5-25. These scoops tend to be very tough on tires. If the inflation is not checked daily and the underfoot conditions are not kept clean, the customer will have more frequent tire issues with a pneumatic tire.

Generally, tires on the scoops are L5 bias or radial tires. An L5 tire is very limited to the speed and cycles that the tires can run in any given shift. Besides cutting being an issue, heat is a major factor. The solid tire has limitations as well, but will run in the same type of operation as an L5 lug or smooth tire. The difference is the tire will not be pulled due to an impact or cuts. There is also no need to check the air pressure on a solid tire, which means more production from the equipment.

Another benefit of a solid tire is the tread depth. A solid tire has more tread depth than a pneumatic tire, which will equate to a longer life cycle for the tire and less downtime of the equipment for the customer. A 26.5-25 smooth L5 tire bias or radial has around 112/32nds (3.5 inches) of tread. The same size solid smooth tire has 297/32nds (9.5 inches) of tread. This alone should be enough to spark some interest from a customer.

When you take the tread depth advantage plus the ride comfort from a 3-stage solid tire, and virtually no downtime due to a solid tire being mounted, your customer should be very interested in making the change.

One additional point that you can explain to your customer is that the solid tires (both industrial and OTR) can be pressed on to their standard flat-base wheel. New wheels will not need to be purchased.

Like always, you should do a site inspection to determine how the tires are being used and inspect the removed tires to identify the main causes of the failure. Talk with the manufacturer of a solid tire and get them involved to help select the proper 3-stage tire for the application. Once you have collected the information, only then you can provide your customer with the facts on the installation of a 3-stage solid tire.

All customers are looking for ways to reduce cost. By taking a different approach and suggesting a better alternative — such as a solid tire versus what they might be buying today — for their underground equipment will have a positive impact on their bottom line costs in the future. Be sure to look at all options that are available to you before making any suggested recommendations to your customer in regards to tires for their underground equipment.