Skid steers are versatile machines that are used in a wide assortment of jobs and applications. They can be used with tires or tracks (compact track loader), with tracks that fit over the tires and can also be used for flotation. The wheels on skid steers typically have no separate steering mechanism. Turning is done by the left-side and right-side wheels turning at different rates of speed. The machine is turned by skidding (or dragging) its fixed wheels across the ground. The rigid frame and strong wheel bearings prevent damage to the machine during skidding. Because skid steers are capable of zero radius turning, this makes them very maneuverable for applications requiring a compact and agile machine.

Skid steers can be used in construction, mines and quarries, landscaping and agriculture. They are used on hard-packed dirt, sand, mud, concrete and asphalt, and they are made to carry heavy loads. Because they have many options for attachments, they can perform a wide range of jobs like digging, excavating and snow removal.

As with most mobile equipment, tires are an important part of the operation and a costly investment. They play a large role in getting the job done and can have a great impact on performance and time. Therefore, the tires that skid steers require need to be designed to handle some of the toughest environments, carry very heavy loads and last as long as possible.

Skid steer tires are made in both solid and pneumatic designs. Solid tires are used mainly in applications where flat tires and cuts and punctures become a problem. For example, in scrap yards or the recycling industry, tires are continuously running over metal and hard, sharp debris. Foam filling can also be pumped into pneumatic tires used in this application to provide stronger protection. Because of the higher cost of foam filling, it is recommended to use deep-tread tires to ensure that the user gets the maximum use from the tire. In this environment, it is important to use a tire that will not easily get punctured.

Pneumatic tires are used in a wide variety of other applications and are more versatile. They cost less than solid tires or foam fillings and are a more economical option. They work best on uneven or rough terrain and provide a more comfortable ride. They come in a variety of tread depths, tread designs and quality levels.

Standard pneumatic tires are used for light- to medium-duty applications such as landscaping, construction and county garages. They generally have less tread depth because heavy-duty traction is not needed. These are entry-level tires and the most economical in terms of price.

Premium pneumatic tires are used for the same duties as the standard tires, but some have added protection for the sidewalls and rim guards to protect the wheel. This is designed to protect against impacts and continuous twisting. The tread depths are generally about the same as standard tires.

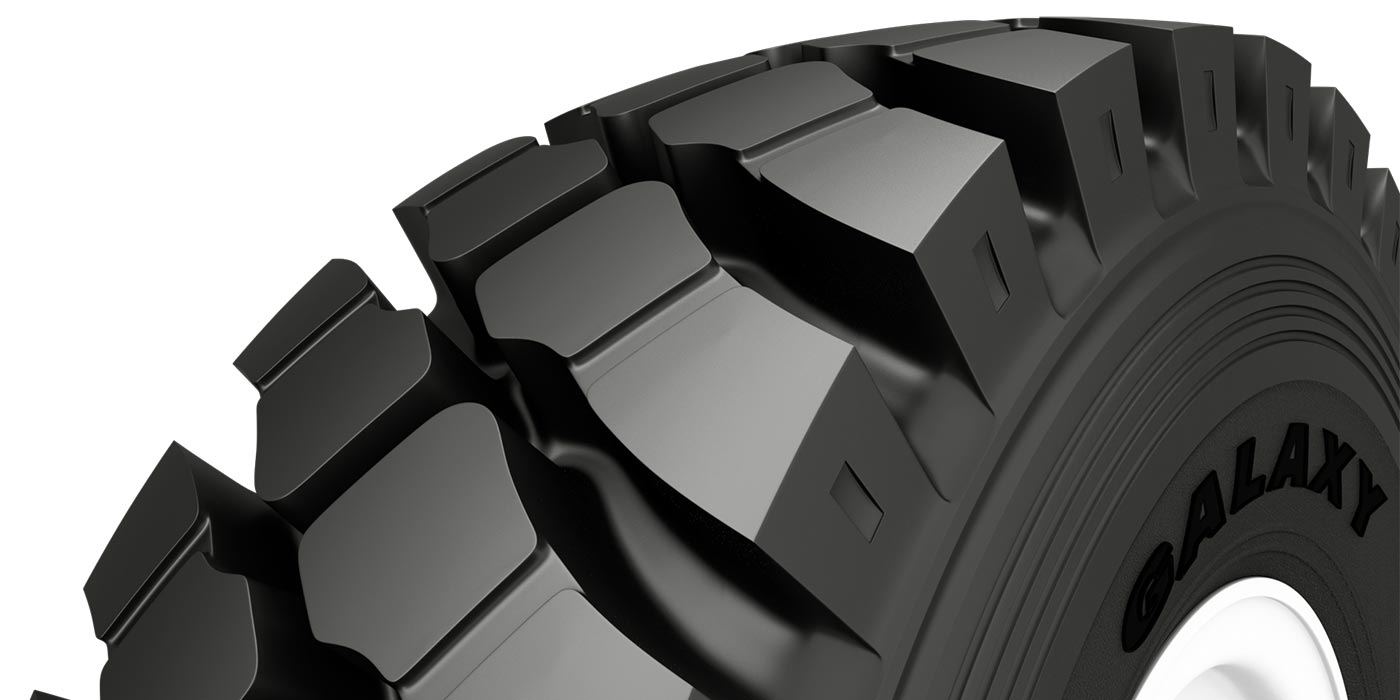

Severe-duty tires are designed for heavy-duty applications. They generally work well in mud and on hard surfaces and can be used in mines, quarries and agriculture. They are made with wear-resistant compounds that work well on abrasive surfaces. These tires generally have an extra deep tread depth and have a larger lug-to-void ratio while being resistant to punctures. These are the best to foam fill as the tread depth is much deeper than standard tires.

Wear-resistant compounds are also used in some tires for severe services or on concrete and asphalt. These compounds help enhance a tire’s life. Cut resistant and chip- and chunk-resistant compounds are added during the manufacturing process to help in applications where puncture resistance is needed. Chip- and chunk-resistant compounds help in hard-service applications during the twisting and turning. Deeper treads are also available for enhanced traction and longer service time.

Increasing ROI

As with all pneumatic tires, running the correct air pressure is important. Running low air pressures will shorten the life of the tire and can cause premature tire failures. The sidewalls flex more, and the rubber can separate from the tire’s carcass. Higher-than-recommended air pressures can lead to impact breaks and casing failures. The tire becomes deformed causing less footprint on the ground and increased bouncing. Therefore, running the manufacturers’ recommended air pressures for the tire, environment and application can maximize the life of the tire and help it perform to its maximum efficiency.

An important part of any operation is to reduce downtime and increase the return on your investment. Therefore, advise your customers to make time to do a little bit of tire maintenance and inspection. Before each job, tell them to check for cuts, punctures and wheel damage that can cause most downtime and failures. This can go a long way in reducing tire problems and extending tire life. Repairing tires when needed and running the recommended air pressures will also save time and money. And, when they need new tires, be sure to recommend the correct tires with the correct loads for your skid steer customers’ applications, so they’ll have the best tires to meet the demands of whatever job they tackle.