They grab, grope and grip but somehow don’t grasp drivers’ gratitude for contributing to a safe ride on roadways.

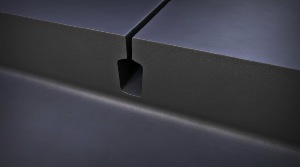

Sipes, sometimes called kerfs, are the narrowest slits found on tread patterns and are often overlooked when customers compare one tire’s attributes to another.  A tread’s aggressive radial and lateral slots, which are wider than sipes, and its broad circumferential grooves take center stage in discussions at a tire dealer’s showroom.

A tread’s aggressive radial and lateral slots, which are wider than sipes, and its broad circumferential grooves take center stage in discussions at a tire dealer’s showroom.

However, siping is an integral component that helps provide better traction, even wear and a smoother ride.

Sipes are molded into a tread during the cure process using sheet metal blades installed in molds and bent into a variety of shapes. They are generally 1/10th-inch or less wide, but some manufacturers give them different specs, according to Tim Richards, a 28-year Goodyear veteran and current project manager for the company’s North America consumer tire development.

The art of siping is attributed to John Sipe’s problem-solving inspiration in a not-so-idyllic location. The story told by tire industry veterans dates back to the early 1920s, when Sipe worked in a slaughter house and became frustrated at constantly losing his footing on wet, sloppy floors. Sipe discovered that by cutting slits in the bottom of his shoe soles, he gained traction.

Goodyear’s Richards says the best way to study sipe contributions is to first examine tires without tread patterns, such as racing slicks. Designed for dry pavements, their smooth treads provide maximum grip and stiffness.

Tread flexibility isn’t necessary to maintain maximum contact because race track surfaces are relatively uniform and flat.

Vehicles on highways are subjected to the vagaries of weather and ever-changing surfaces, while their owners look for specific performance attributes that require a broad range of tread designs. Sipes help fine-tune each tire’s handling, traction, ride and wear characteristics.

Tom Kenny, another 28-year veteran of the industry and current Hankook manager of tire development engineering, uses “kerf” instead of “sipe” and defines it as a slit that is one millimeter or smaller.

“Snow traction is the major attribute of kerfs,” says Kenny. “A tire needs biting edges in the winter, so the more places to collect the snow, the better.”

Kenny says an inspection of the most popular size of Hankook’s Optimo H725 all-season tire reveals it has 49.8 feet of radial slots around the complete tread. “Kerfs add another 70.6 feet, more than doubling the slots’ length of biting edges in the tire.”

He noted that one Optimo, when properly inflated, puts nearly 11 feet of slots and sipes in contact with the ground at all times, so a vehicle’s four-tire footprint adds up to almost 44 feet of edges gripping the highway pavement.

Richards explains that bona fide winter tires customarily have the most sipes, but the extra grip comes at the expense of stiffness. The sacrifice, which he likes to call “customizing” vs. “compromising,” for more snow traction at the expense of cornering capability is welcomed by drivers caught in a blizzard but loathed by sports car enthusiasts tackling a summer road course. Hence, changeovers occur from snow tires when warm weather returns.

Another sipe contribution, secondary to snow handling, is wet traction, says Kenny, so it becomes a balance of desired performance traits for tires on a variety of pavement conditions. He says a tire with only slots and grooves to vacate water works to a certain degree, but with heavier rain and higher speeds, surface water would build into a wall in front of its tread. Adding sipes helps channel more water away, so less hydroplaning occurs.

Richards and Kenny explain that sipes also are used to make tires seem quieter. When squashed, deformed and released, a tread literally pumps air in and out of its footprint at the leading and trailing edge of each rubber block. The resulting vibrations or harmonics occur at changing frequencies, similar to sound produced by a stereo speaker.

“Placing sipes in a block increases flexibility that can reduce noise levels,” says Richards, “but the slits create smaller blocks that provide additional sound-generating sources at higher frequencies.”

Kenny says tread designers intentionally vary the depth of sipes for noise control.

“Some sound pitches created by kerfs may be unpleasant, while others are acceptable,” says Kenny. “Varying the kerfs’ widths, depths and locations creates multiple pitches. More noise may be generated and one pitch may sound better than another, but spreading the tones across a wide sound spectrum creates a white noise that can be tweaked for a pleasant profile.”

Sipes are cut shallower than the full tread depth to help keep each rubber block stiffer, allowing the tread to handle steering requests. Sipes also assist with heat dispersion in any tire, however the radiator-like action is more important to larger tires with deeper tread patterns.

While sipes cannot extend the inherent life of a tire, they can promote even wear, says Kenny. “New asphalt is relatively smooth, but weather and traffic take their toll, creating a coarse texture. Flexibility created by sipes helps individual tread blocks to conform to a highway surface, enveloping the smallest changes in a pavement. Without sipes, wear would first occur on the front and back edges of a tread block. With sipes, wear occurs at points across the block.”

Radial sipes on a tread pattern help provide traction during braking and acceleration. Circumferential slits running parallel to a vehicle’s forward motion help provide grip for cornering. Lateral or diagonal sipes help with all vehicle movement and, when used on directional tires, help vacate water to prevent hydroplaning.

Sipe Evolution

When first introduced to tires, sipes were one-dimensional cuts. Zigzag patterns looking like the side view of a washboard were soon utilized to assist on ice and snow. The next technological advancement was the waffle iron pattern, a small, interlocking texture that created more edges for traction while retaining more tread stiffness for cornering.

Kenny says some tire tread designs now use 3-D sipe technology that actually changes direction inside the tread. The two edges created by the cut can interlock to re-stiffen a rubber block when making contact with the roadway.

Goodyear has announced a new concept in sipe technology for its latest all-season passenger tire. Evolving Traction Grooves, or ETG, will be featured on the next generation Goodyear Assurance TripleTred, scheduled to be available in June.

Designed to help the tire maintain traction in rain and snow as it wears, ETG is formed by a bulb-shaped blade in the tire mold. The slit starts at the tread surface like a conventional 1/10th-inch sipe, but expands under the surface, almost like an onion shape embedded partway into the tread. ETG maximizes road surface contact when the tire is new, but enhances traction as wear occurs, compared to conventional sipes.

Post-manufactured siping lends itself to another sometimes controversial discussion. Tire engineers already have designed tread patterns for optimum performance from specific tires and feel additional cuts or slits are unnecessary. To be clear, Goodyear says its tread life limited treadwear warranty does not apply to tires after leaving its factories if the tread pattern has been altered in any manner, including but not limited to, siping.