ep-by-step wheel installation policy, a back-shop tool-placement and layout standardization and a work order barcode scanner to ensure the highest level of program sustainability and data collection.

“The application of Lean and Six Sigma tools has helped us reduce variability in our distribution routing and delivery process,” he adds. “Many more improvement opportunities, too numerous to address, have been exposed and are in some state of correction and further study.”

Dunn’s combined use of Lean and Six Sigma, however, raises questions about how the two systems co-exist and complement one another.

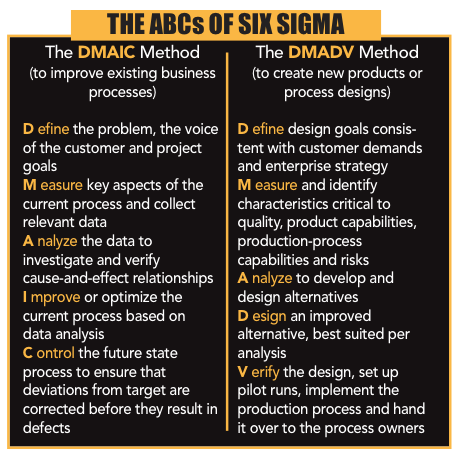

“At Dunn, we’ve chosen to concentrate on the use of Lean and its tenet of ‘plan-do-check-act,’ as it is more readily accepted and applies more appropriately to the non-statistician that you find common to the tire industry,” Schroeder explains. “The Lean P-D-C-A and the Six Sigma define-measure-analyze-improve-control cycles have much in common in function and form, but Lean allows us to move at a greater speed. (See sidebar for more information on process cycles.)

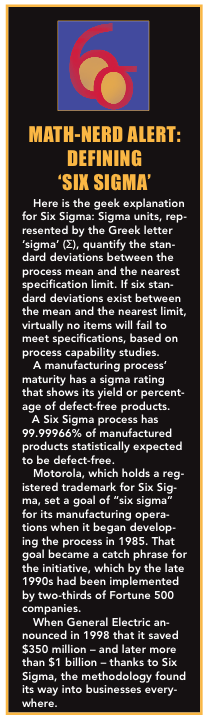

“In our industry, we must often work from a very controlled seat-of-the-pants point of view, to allow us to ensure value but also to adapt quickly to the changing needs of our customers, both internal and external,” he adds. “We have chosen to use Six Sigma as our data-driven chainsaw-in-the-closet. We Lean it out first. If that proves to be unsuccessful for process correction or the removal of waste, we then tear the process apart using that Six Sigma chainsaw and use the data drill to pluck out the errors and defects.”

Exactly what statistics has Dunn evaluated in this “non-statistician’s” industry?

Schroeder says the company has looked at:

• Process function time data, to create greater process flow, increase value and shorten process time;

• Communication system data, to properly size staffing and create better manpower planning and growth;

• Vehicle year, make and model data, to aid in forecasting and inventory placement;

• Product pick/ship flow data, to improve warehouse floor operations and to add value for the end-user.

Dunn used statistics-analyzing computer software, called Minitab, to help with the data drilling, along with Microsoft Excel. In the end, costs were reduced and process time was shortened.

“Right-sizing manpower, controlling tool-and-equipment costs, improving call-and-contact flow, and the greater assurance of quality by enhancing the perception of process ownership at all levels” all were achieved, according to Schroeder. And the only significant detriment to that achievement, he says, was simply resistance to change.

“That’s always a condition we must combat,” Schroeder says. “There are those who are not as willing to accept new concepts and culture.”

Criticisms leveled at Six Sigma by detractors include its similarity to previous improvement programs; its rigidity and potential to inhibit creativity in the name of process; its overselling by improperly educated consultants; and other issues rooted in math and statistics.

Nevertheless, Schroeder credits Dunn’s upper management for initiating the Six Sigma change and seeing it through.

“After their own Platinum Belt training, our executive team has led a successful culture change,” he says. “Their passion for value has been exhibited daily in the way in which they conduct their daily interactions with our people. They understand the value of a true Lean Six Sigma champion, and that true change can only start at the top.”