In past series of “The Science Behind,” we have covered topics like tire basics, fuel efficiency, noise and run-flat tires. Now, it’s time to talk about two of the most impactful day-to-day aspects of vehicle and tire performance: ride and handling.

Ride and handling, in short, is defined as how a vehicle acts during a drive, how a car responds to steering input and how comfortable it is for passengers inside the vehicle. These are the first impressions someone will have when they purchase a vehicle; therefore, it is a highly sensitive subject for car manufacturers.

In this article, we will briefly review the definition of ride and handling performance and the effect of the tire on those performance aspects. Finally, we will discuss some of the vehicle manufacturers’ requirements relating to ride and handling.

Ride and Handling Features

Vehicle and tire manufacturers often use ride and handling as umbrella terms to cover a much broader scope than the actual meaning of the words. Unlike most other tire performance metrics, ride and handling is important when you’re talking about the OE fitment, or the tire that was designed specifically for that vehicle. It is a less critical component of replacement tire development when the tire is designed for a range of vehicles.

Each vehicle manufacturer has its own criteria to evaluate ride and handling performance. As a result, the criteria evaluated by tire companies can be different depending on which vehicle manufacturer they are working with on a given project.

The first step in developing a vehicle is to set up the vehicle dynamic requirements. Obviously, each brand/model has different requirements based on the vehicle model’s objectives. For example, there are fundamental differences between vehicle dynamic requirements for a Toyota Supra, BMW 340i or a Nissan Altima. Vehicle dynamic requirements will be translated to requirements for the tire’s characteristics that will be sent to tire manufacturers. Then, tire manufacturers will use that data to design the tire, matching or exceeding the requirement

Tire Characteristics

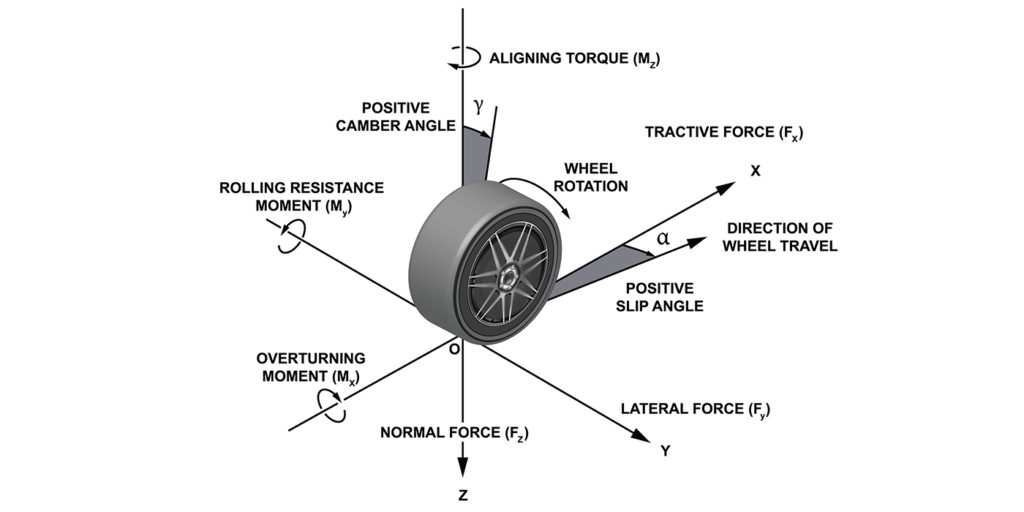

Vehicle dynamics are closely related to tire characteristics, otherwise known as or “force and moment.” Tire force and moment measurements are used to provide insight into how a tire’s design affects the overall vehicle dynamics of a car, according to research from the University of Michigan.

All characteristics of a tire’s ride and handling are summarized into six components. The photo below demonstrates the characteristics. These six components can provide a complete picture of tire performance.

- Tractive (Longitudinal) force, FX: The force of the road on the tire along the X-axis. The longitudinal force causes the acceleration/deceleration of the vehicle, depending on whether the tire is driven or braked. Positive longitudinal force (driving/driven force) is an indication that the tire is driven. Negative longitudinal force (braking force), is an indication that the tire is stopped.

- Lateral force, FY: The force of the road on the tire along the Y-axis. Lateral force will cause a vehicle to move to the left or right depending on whether the tire is steered/cambered to either side.

- Normal force, FZ: The force of the road on the tire along the Z-axis. It is the contact force between the road and tire and will be on the contact patch. Normal force is always negative due to the direction of the force.

- Overturning moment, MX: The moment about the X-axis. Overturning moment is the effect of left-to-right displacement of the point of action of the normal force with respect to the contact center. Overturning moment will affect camber behavior and will often be used for finalizing camber adjustments, especially on race cars.

- Rolling resistance moment, MY: The moment about the Y-axis. Rolling resistance moment represents the fore-aft displacement of the point of action of normal force with respect to the contact center.

- Aligning moment, MZ: The moment about the Z-axis. It represents the point of action of the shear forces (longitudinal and lateral force) within the road plane.

In addition to six tire characteristics, there are few other parameters that affect overall vehicle dynamics and tire performance.

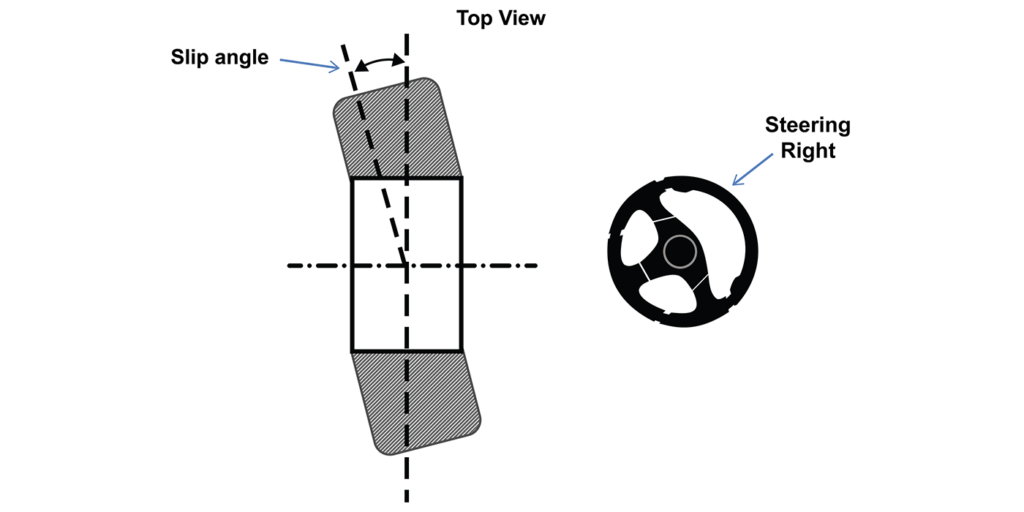

- Slip angle: As it is shown in the graphic below, slip angle is the angle between a rolling wheel’s actual direction of travel and the direction towards which it is pointing. In other words, this tire deflection gives rise to the slip angle and to the cornering force. The cornering force often increases linearly for the first couple of degrees of slip angle, and then increases non-linearly to a maximum before decreasing as the tire slips.

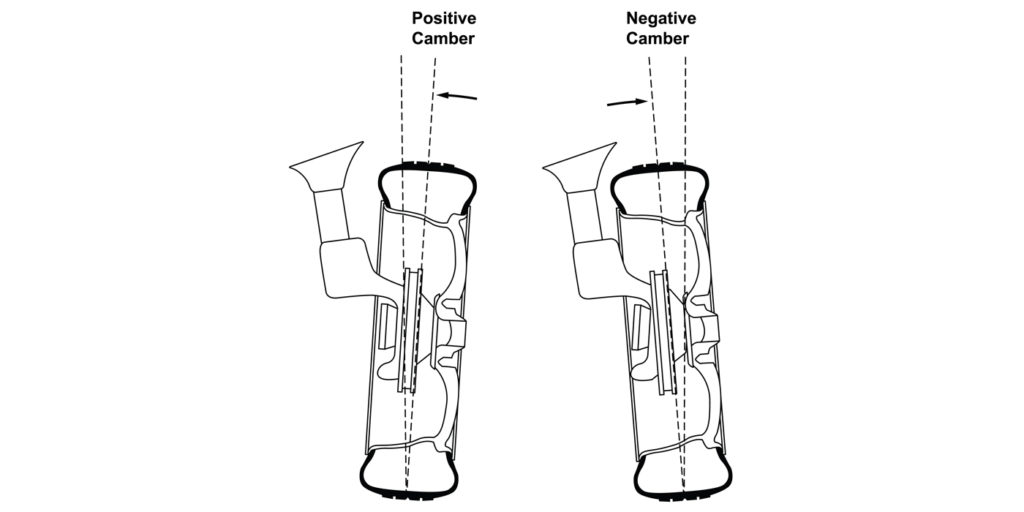

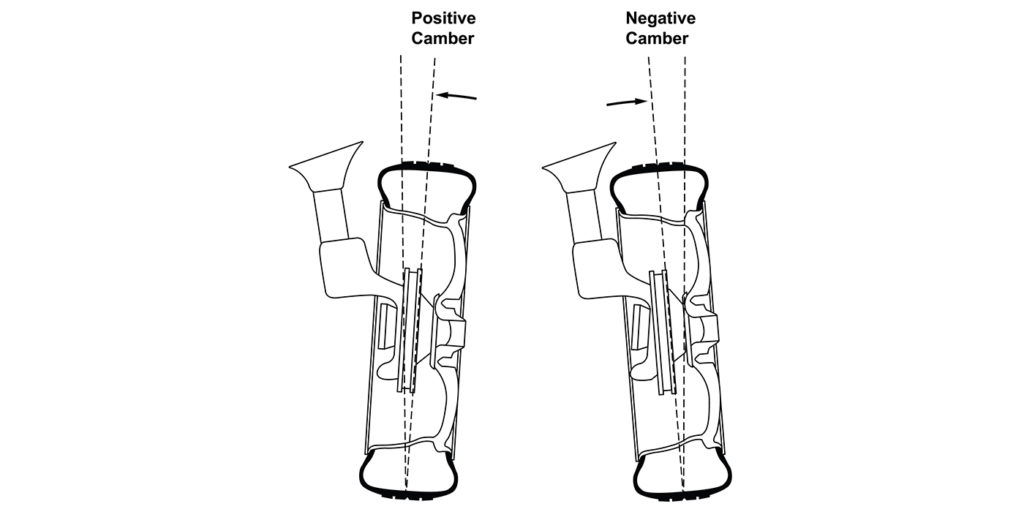

- Camber (inclination) angle: The angle at which the wheel and tire stand relative to the road—assuming it is perfectly flat—is the camber angle. The easiest way to envision what camber looks like is to view the wheel and tire head-on. When stationary, the tire maintains a static camber angle, whereas, when the car is cornering, due to body roll, the contact patch is reduced. In order to counteract this effect and have the greatest amount of tire on the road while cornering, camber settings must be taken into consideration and adjusted accordingly.

Cornering stiffness (Ca): This refers to a consistent number that defines lateral force as a function of slip angle. Cornering stiffness of a tire is its ability to resist deformation in the shape of a tire while the vehicle corners. Tires with lower stiffness represent lower corning stiffness, and therefore, are more flexible.

The values of cornering stiffness and cornering stiffness ratio of the front/rear of vehicles are the most important characteristics related to handling. Tire engineers spend a lot of time correlating subjective vehicle handling feedback to cornering stiffness and front/rear ratio to achieve the new cornering stiffness and delivering the desired handling.

Vehicle dynamics is an advanced engineering course in universities and cannot be summarized in a few pages, however, we will cover some of the more important criteria.

Ride Quality

In short, we refer to ride as a characteristic of tire and vehicle attributes with respect to the comfort of the driver and passengers inside a vehicle. The perfect tire will dampen all surface irregularity and provide a smooth, comfortable ride. Tires designed for grand touring vehicles like Cadillac, Lexus and Lincoln are specifically designed to provide an ultimate, comfortable ride.

When it comes to the design and evaluation of a tire for comfortable ride, the following performance attributes are closely monitored.

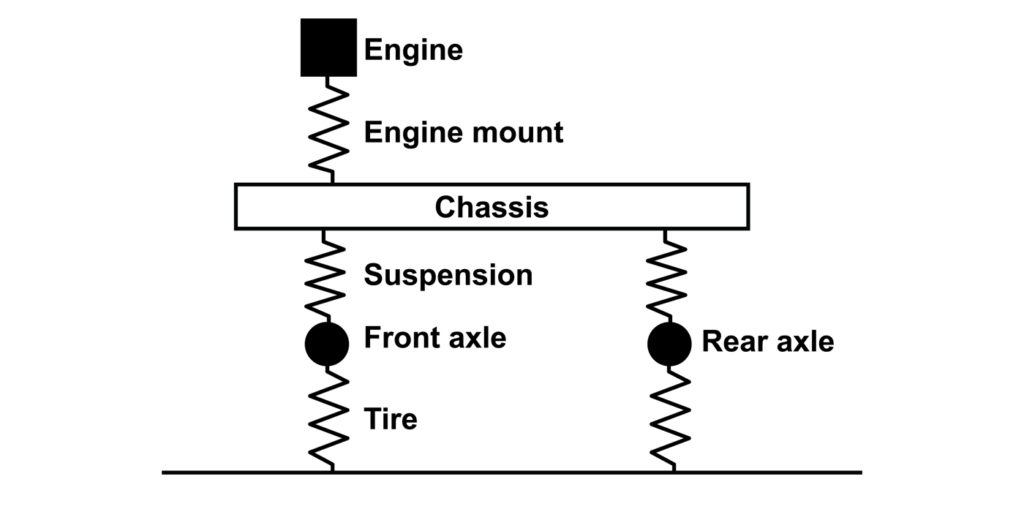

Bounce memory: The vehicle’s engine is supported by elastic mounts to isolate the chassis from the engine’s vibration (Figure 4). Together with the engine’s mass, they form a system with several natural modes in the frequency range from five to 30 Hz. When these modes are excited by road unevenness, they can be felt inside the car as bounce memory or shake.

When the frequency of the axle is shifted close to the frequency of the engine, a strong excitation of the engine may cause a strong bounce memory (shake) inside the vehicle. Subjective evaluations have shown that increased tire stiffness (i.e., higher shore tread compound, higher stiffness steel, nylon or polyester) will change the natural frequency and reduce the bounce memory by moving the natural frequency further from the excitement frequency.

Sometimes, the lack of tire uniformity (tire roundness) may create a vibration and be mistakenly evaluated as bounce memory.

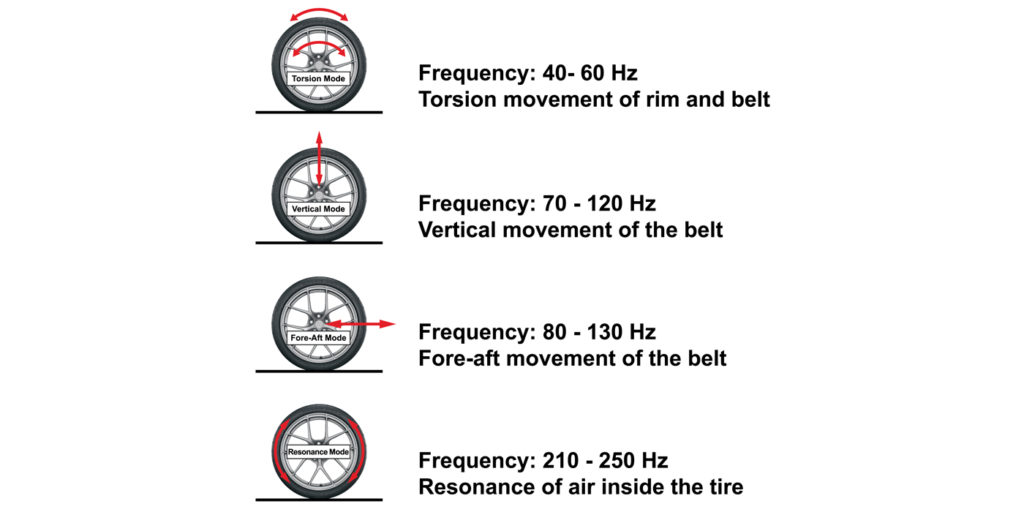

Acoustic damping: When the vehicle goes through an obstacle/bump, the tire will get excited in an audible frequency range in different modes (Figure 5). These vibrations are transferred into the car via the suspension and contribute to the interior noise known as acoustic damping.

Tires with lower damping capability will transfer more noise to the passenger and driver and cause less-than-desired ride conditions.

When the acoustic damping of the tire is too low, the sound can still be heard even after the car has already passed the obstacle. When the car passes from a smooth to a rough road, the increase in noise level is too high, therefore providing a tire with optimal damping that can significantly improve the overall ride performance. Studies show higher tire stiffness, and/or reduction of tire weight can improve the acoustic damping.

A smooth ride is more often directly related to the uniformity of the tires mounted on the rim and in connection to a specific vehicle (uniformity requirement). The assessment is made subjectively on the basis of which of the vehicle’s vibrations are perceived as unpleasant.

Improvements to ride are complex, as the tire, wheel or tire/wheel assembly can significantly change the effects of ride individually or altogether. While very little correlation between low-speed uniformity and smooth ride (vehicle transfer function) exists, there is a good correlation established between smooth ride and high-speed tire uniformity. Often, a high value on low-speed uniformity can be indicated by a rougher ride, however, a lower value of uniformity may not guarantee a smooth ride.

In general, measures that make the tire softer have a favorable effect on high-speed tire uniformity. Excellent bead seating, correct belt lift during curing, joint-less nylon overlay (cap ply), softer compound and consistent touchless manufacturing are only a few items that can improve high-speed uniformity, which eventually improves the ride of the vehicle.

Handling & Steering

Compared to ride, handling is a broader term, however, as mentioned earlier, the term refers to how well the vehicle handles the road (straight or curved; dry, snow or wet; slow or fast) and how well the vehicle responds to steering input.

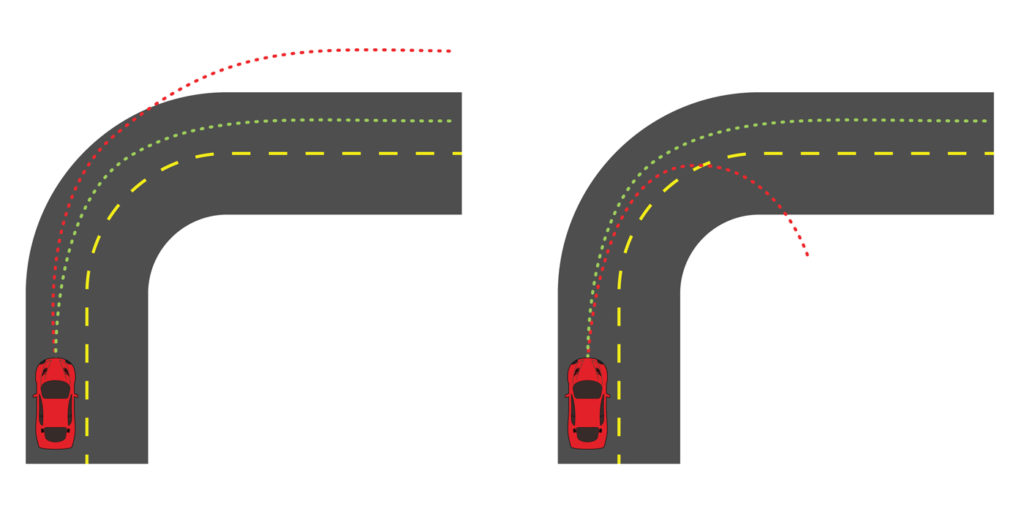

Oversteer occurs when a car steers more than the driver’s input. Understeer occurs when a car steers less than the driver’s input.

The ratios between the slip angles/cornering stiffness of the front and rear determine the vehicle’s response on a turn. Slip angle is the difference between where a car is pointing (heading) and where it’s actually going. The cornering stiffness of a tire is its ability to resist deformation in the shape of a tire while the vehicle corners.

If the ratio of front-to-rear slip angles/cornering stiffness is greater than 1, the vehicle will tend to understeer, while a ratio of less than 1 will produce oversteer. In other words, in an understeer situation, the front slip angle is higher than the rear slip angle, causing the front of the vehicle to swing away from the direction the car was turning. In oversteer, the rear slip angle is higher than the front slip angle, causing the rear end to swing away from the direction the car was turning. See Figure 6 for both oversteer and understeer conditions.

Vehicle manufacturers tend to develop vehicles favoring understeer as it has less risk, and it is easier for drivers to recover. In tire design, the ratio of belt width to overlay (cap ply), belt angle and amount of under-tread gauge ratio of the tire center and shoulder, tread compound durability, turn up and apex height are used as tuning elements to move the cornering stiffness from one side to the desired side.

Stability, Linearity and Delay

Stability is the ability of a vehicle to drive straight down the road with minimal corrections. This includes crosswind and groove sensitivity. Obviously, the longer the tire maintains a straight path, the better the tire is performing in this regard.

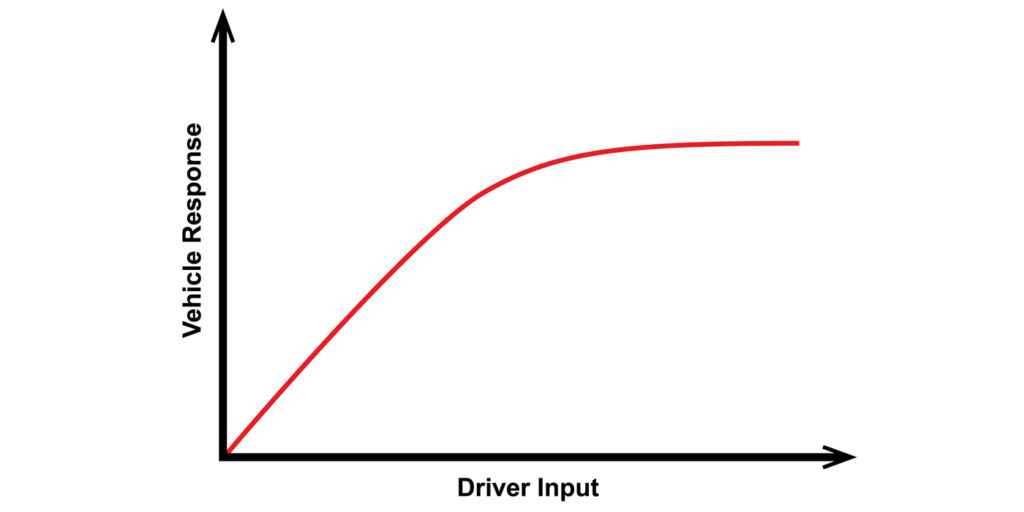

Linearity is steering response to a constant rate increase to steering input. In normal driving, we do not require very large forces from the tires, so we often operate in the linear range of the tire. Simplified, if we turn the steering wheel 5% more, the car will turn 5% more. During emergency maneuvers, the tire will often reach its saturation point and turning the steering wheel 5% more might make the vehicle turn only 2% more. This change in behavior can reduce the driver’s chances of successfully carrying out the maneuver (see Figure 7).

Delay is the lag between steering wheel input and initial vehicle response. The effort is to reduce the delay between driver input and tire response to the input.

In general, any measures that can change the shape of the footprint and pressure distribution across the footprint can affect stability, linearity and delay. The original contour and pattern design can most influence the footprint shape. However, at later stages of development when the mold is finalized, measures like belt angle, belt width, under-tread gauge, type of ply material, height of the apex and turn up can improve steering.

Vehicle manufacturers and tire suppliers evaluate the tire/vehicle pairing on wet handling and dry handling. Of course, for all-season and winter tire evaluation, snow handling is as important as dry and wet evaluation. Depending on the type of vehicle, the evaluation is normally conducted in both loaded and/or unloaded situations. This is especially true for pickup trucks where rollover sensitivity needs to be tested.

Most of the time, ride and handling are target conflicts and, therefore, improving one will decrease the other. Reaching a balance between ride and handling is the key to tire development based on vehicle dynamic input.

In general (but not always), tires with round and smaller footprints can provide a better ride, and tires with wide and flat footprints can provide better handling. Therefore, higher belt angle, narrower belt width and higher under-tread gauge in the center can provide a rounder footprint and often improve ride. In contrast, a lower belt angle, wider belts and lower under-tread gauge in the center can do the opposite and improve the handling.

Vehicle manufacturers often conduct objective and subjective ride and handling evaluations in order to find optimal tires to select for the specific vehicle application.

On the objective side, use of vehicle modeling software enables them to predict vehicle dynamics by inputting tire force and moment information and vehicle data into the software.

Despite all the improvements to modeling in recent years, vehicle manufacturers still rely heavily on subjective analysis to evaluate tires on the vehicle and provide feedback for further development or final confirmation.

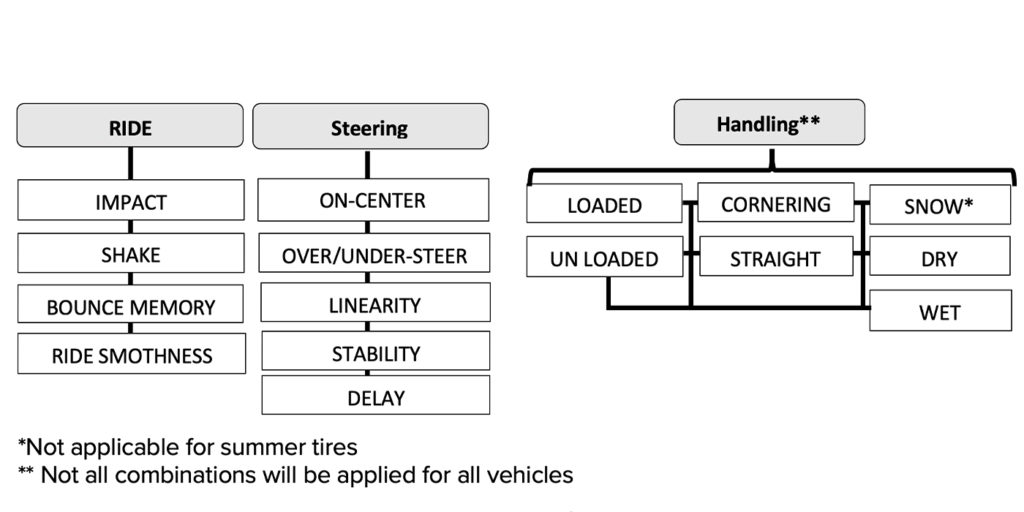

Although the criteria for evaluation are vastly different from manufacturer to manufacturer, Figure 8 shows typical areas of evaluation.

Final Thoughts

You now know that ride and handling are some of the most complex and subjective aspects of tire development, and also some of the most important to the vehicle manufacturer and consumer satisfaction. Hopefully, this article has provided you with some insights and understanding to the science behind ride and handling and the importance it plays in tire development and in the everyday enjoyment of our vehicles.

It is the relentless pursuit of improvement and excellence by dedicated engineers and visionaries that now allows us the ability to experience vehicles and tires with incredible power, responsiveness and ride comfort that simply wasn’t possible in the past. And, it is that same determination and dedicated scientific inquiry that will lead tire development to a place in the future that we might not have even imagined.

Check out the rest of the November digital edition of Tire Review here.