Something in every vehicle needs to carry the vehicle and payload. It just so happens that the black, round objects in the four corners of the vehicle are designed to do the job, and the amount of weight they can carry is known as the tire’s load-carrying capacity.

When we started the “Science Behind” series in Tire Review, we discussed the load capacity in detail, so we are going to skip it in this article.

In short, the load-carrying capacity of a tire is a function of tire size and the amount of pressure that tire holds. Obviously, the bigger the tire is, the higher load carrying capacity is. The two or three digits after the rim diameter on tire sizing are known as service descriptions. Service descriptions show the maximum loading capacity of a tire allowed on it and specifies the maximum condition that the tire can be run.

Typical passenger tire load index, along with the maximum loading capacity at maximum pressure, is also available on the tire sidewall.

Until recently, passenger tires were identified as light load (LL), standard load (SL) or extra load (XL) on the sidewall. This is the same in both P-metric and Euro-metric sizes, however, the inflation pressure at maximum load slightly varies between the two. With the advancement in the vehicle world and the introduction of heavier vehicles into the market, the need for a higher load-carrying capacity tire has surfaced. Vehicle needs have changed, so tire design needs to be adopted, too.

New Trend in the World of Vehicles

Not long ago, the majority of the design on vehicles was centered around lighter vehicles and better fuel-efficient components. As a result, existing tire loading was good enough to manage the vehicles. If vehicle manufacturers wanted to go to higher vehicle weight, they simply moved to bigger tires or moved from a standard load (SL) tire to an extra load (XL) tire. This remained unchanged until recently.

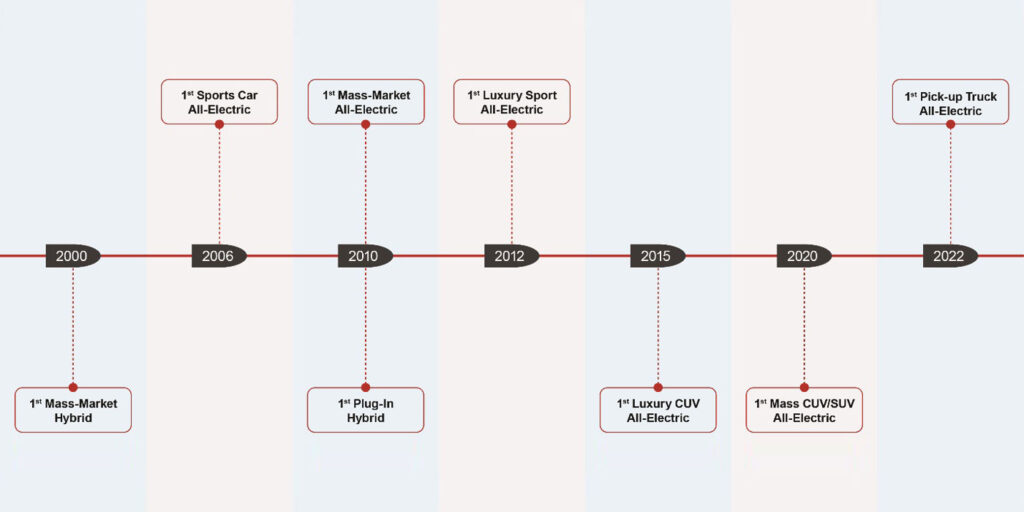

Electric vehicle (EV) and hybrid concepts are not new but they are changing the world of tires. As shown in figure 1, Toyota was the first company that brought hybrid vehicles into mass production, and it sold over 15 million of them globally. Following that in 2006, Tesla debuted the first EV sportscar and successfully launched it into the market. In the next 12 years, the EV vehicle market slowly shaped. EV cars got more reliable and with the support of incentives, people got attracted to them. In 2022, 4.5% of total vehicle sales are expected to be EV vehicles. This is still a fraction of the total vehicles in the market; however, this number is expected to reach 10% by 2026 and grow to 20% by 2030.

EV vehicles are fundamentally different from internal combustion engine (ICE) vehicles. They have no engine. They are quiet. They are smart and need to be charged. But EVs are heavier than comparable ICE vehicle models.

Ford’s Mustang Mach-E weighs 500 pounds more than an Edge. Tesla’s Model S weighs over 4,900 lbs., whereas an ICE sedan vehicle like the 2021 Toyota Camry weighs up to 3,572 lbs. The Ford F-150 Lightning will weigh about 1,600 pounds more than a similar gas-powered F-150 truck. Similarly, the electric Volvo XC40 Recharge weighs about 1,000 pounds more than a gas-powered Volvo XC40.

High Load Tire Concept

As we know, electric cars generally weigh considerably more than their ICE vehicle counterparts, and a higher vehicle load requires a higher load-capacity tire. With most EV and hybrid vehicles, tires are already at the maximum load-carrying capacity of an XL and due to the limited space, moving to a bigger size would not be practical. So once again, the tire needs to be re-invented.

Tire engineers had to rethink the load-carrying capacity concept. Due to innovations in tires – from construction and type of material to exceptional modeling tools – tires can now achieve a higher load at the same pressure.

While this was great news to the automotive industry, there was no standard to regulate the concept. The tire industry approached standardizing bodies both in the USA (Tire and Rim Association) and ETRO (European Tire and Rim Organization) and the high load concept was established. The ETRO established the high-load concept in its 2021 book with a high-load tire table.

Rudy Consolacion, executive vice president of TRA, told Tire Review that the organization approved engineering guidelines for HL tires, based on ETRO standards, at the end of last year. With the guidelines established within TRA, its members can now request HL tire sizes to be standardized in its 2023 Yearbook.

More: Continental Introduces First Tire with ‘HL’ Load Index

According to ETRTO, high load (HL) capacity tires are extra load tires that are designed to carry a higher load at the same reference pressure. The prefix “HL” must be stamped on the sidewall in front of the tire size designation. Pressure for standard load (SL) is at 36 psi, while both extra load (XL) and high load (HL) are specified at 42 psi. Figure 2 shows the sidewall of a tire with HL designation.

Table 1 shows an example of a tire with three SL, XL and HL suffixes/prefixes. The same tire size as the extra load is carrying 12% more load compared to the standard load tire. The same tire size as the high load (HL) is carrying 23% more load compared to the standard load (SL) and around 11% more compared to the extra load (XL) tire.

| Tire Size | Load (lbs.) | % to SL | Pressure (PSI) |

| 245/40R19 SL 94 Y | 1,477 | 100% | 36 |

| 245/40R19 XL 98Y | 1,653 | 112% | 42 |

| HL 245/40R19 101Y | 1,819 | 123% | 42 |

Let’s look at an example of a new EV car with a curb weight (vehicle only) of around 5,236 pounds. and a gross weight (vehicle and payload) of about 6,500 pounds. The car is equipped with 245/35R21 tires in the front and 265/35R21 on the rear. An XL tire 245/35R21 can carry 1,565 pounds in the front, and the rear tires (265/35R21) are capable of 1,819 pounds maximum load. With this setup, the total weight carrying capacity of the four tires would be around 6,768 pounds. With a gross weight of about 6,500 pounds, the extra load (XL) tires would not deliver enough reserve for the vehicle to safely operate on the street, so a different tire size or high load tires are required. With the HL concept, HL245/35R21 can carry around 1,709 pounds and the HL265/35R21 tire is able to carry 1,929 pounds. With the HL setup, the total load carrying capacity of four tires would be increased to 7,276 pounds. This is enough reserve to safely fit the vehicles with the existing tire setup.

Summary

The high load (HL) concept is not solely for EV and hybrid vehicles. The concept is currently in use for a handful of other OE vehicles which are fitted with HL tires. The new concept will allow vehicle manufacturers to stay with current tire sizing without the need of a bigger wheel and tire package and can control the overall cost of vehicles.

Obviously, this is not the last challenge in front of tire engineers. As the vehicle landscape is changing, other new challenges will surface. One thing is for sure, tire engineers will always find a solution to move forward.

Fardad Niknam is Yokohama Tire Corp.’s director of segment development. He has held previous product development positions at Continental Tire, Toyo Tires and Carlisle Tire & Wheel. He holds two patents and has written over 30 papers on tire development and performance.