As an essential piece of equipment for tire dealerships and vehicle repair shops, brake lathes perform the  important function of machining vehicle brake drums and resurfacing brake rotors. Key for this vital tool and its accessories is spindle speed, feed rate and the ability to produce a quality surface finish for proper vehicle braking and extended friction life. With today’s latest brake lathe technology, technicians can experience quicker production, superior surface finish, easier operation and a longer machine service life. Read on for some of the latest offerings in this segment.

important function of machining vehicle brake drums and resurfacing brake rotors. Key for this vital tool and its accessories is spindle speed, feed rate and the ability to produce a quality surface finish for proper vehicle braking and extended friction life. With today’s latest brake lathe technology, technicians can experience quicker production, superior surface finish, easier operation and a longer machine service life. Read on for some of the latest offerings in this segment.

Ammco

According to Ammco, rotor refinishing is more complex today than ever before, so speed and feed combination is critical. The Ammco 4000E provides control over the entire process and is easily adaptable to any rotor or drum material available today. According to the maker, the digitally-controlled feed rates make it easier to find that “sweet spot” for a particular application, allowing for the highest quality finish possible. Integrated positive rake tool bits allow for precision turning, with reduced chatter to produce superior machined surfaces every time, Ammco added. The 4000E is engineered to handle light truck and SUV applications, with a one-inch, heat-forged arbor that allows for machining larger, heavier jobs up to 200 lbs.

ammcoats.com

DCM Tech

DCM Tech said its SG 7100 brake rotor grinder resurfaces rotors to OEM or better finish and accuracy in minutes. Crosshatch ground finish grinding provides a precision friction surface, ensuring optimum braking performance and brake pad life, the company added. There is minimum stock removal – less than with  turning methods – keeping rotors in service longer. The machine saves money and resources while providing a superior surface finish, allowing for repair and reuse rather than replacement. DCM added rotors can be resurfaced in as little as five minutes with the easy-to-use, bi-directional auto feed system. Wet grinding eliminates airborne dust and provides consistent results.

turning methods – keeping rotors in service longer. The machine saves money and resources while providing a superior surface finish, allowing for repair and reuse rather than replacement. DCM added rotors can be resurfaced in as little as five minutes with the easy-to-use, bi-directional auto feed system. Wet grinding eliminates airborne dust and provides consistent results.

dcm-tech.com

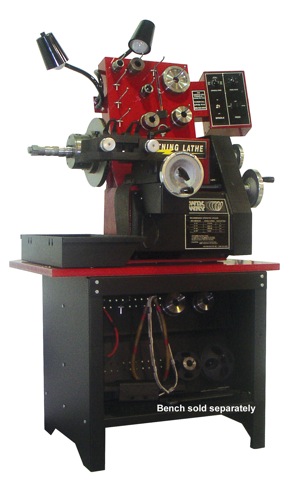

Kwik Way

The 104 One-Minute “Lightning Lathe” is the world’s fastest brake lathe, according to Kwik Way, cutting automotive and light truck drums and rotors in less than one minute. One-pass technology, variable spindle speed and feed rates provide a quality finish on every job, for any diameter. The lathe meets or exceeds OEM specifications and allows for more jobs in a shorter period of time, the maker added. Kwik Way said its brake equipment is backed by a guarantee of quality and service with the company’s 5-2-1 warranty program and is supported by a complete line of parts and supplies.

kwik-way.com

Hunter

Hunter said its OCL430HD is built to keep up with the needs of heavy-duty brake service. Designed with a unique staggered cutting pattern, the OCL430HD prevents the radial “push-out” effect of the typical spiral pattern. Regardless of cutting speed, the quality and finish surface remains consistent and meets or exceeds OE specifications, the maker said. Additionally, the oscillating machining speeding prevents the buildup of vibration and eliminates chatter.

hunter.com

Pro-Cut

Done correctly, every brake job requires a technician to measure the rotor before and after machining. Unfortunately, according to Pro-Cut, most shops have trouble finding a micrometer to perform this simple service.  Pro-Cut said its G2X Digital Cutting Head is an innovative new upgrade package for its on-car lathes that addresses the dilemma. The G2X Digital Cutting head serves as an on-board micrometer. The LED display on the computer box that has traditionally shown run-out measurements is only used to display the distance between the cutting bits every time the cutting arms are adjusted, so a technician knows exactly how thick the rotor is before, during and after machining, the company said.

Pro-Cut said its G2X Digital Cutting Head is an innovative new upgrade package for its on-car lathes that addresses the dilemma. The G2X Digital Cutting head serves as an on-board micrometer. The LED display on the computer box that has traditionally shown run-out measurements is only used to display the distance between the cutting bits every time the cutting arms are adjusted, so a technician knows exactly how thick the rotor is before, during and after machining, the company said.

procutusa.com

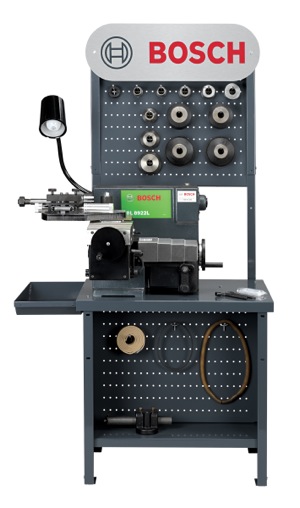

Bosch

Bosch said it offers a portfolio of bench brake lathes that machine most drums and flywheels, and all types of rotors. The BL 8922L lathe is approved for machining rotors to high OE standards and specifications. The BL 8944L lathe has three available arbor speeds, and machining times as low as four minutes. The BL 8989L heavy-duty lathe has a full 10-inch drum facing width and features two arbor speeds for safe truck machining. Bosch added it offers a complete program of technical data,  hands-on training, various tooling and bench configurations for a shop’s needs.

hands-on training, various tooling and bench configurations for a shop’s needs.

boschdiagnostics.com

Snap-on

Snap-on Equipment recently introduced two new brake lathes, the John Bean 401 and 201, which the maker said provide a fast, one-cut finish and are designed to handle a large range of rotor and drum sizes. Both the 401 and 201 lathes are UL/CSA listed. The John Bean 401 brake lathe is designed to service a broad variety of car and truck rotors and drums. It is capable of resurfacing up to 5-inch rotor/flywheel faces and 30-inch diameter drums with a 9-inch drum face. The advanced design enables a quick changeover from disc to drum tools, and its drive shaft and arbor are supported by extra-large tapered roller  bearings, according to the company. The John Bean 201 is designed to handle automobile and light truck drums and rotors. It offers a quick changeover from disk to drum tools and a one-cut finish.

bearings, according to the company. The John Bean 201 is designed to handle automobile and light truck drums and rotors. It offers a quick changeover from disk to drum tools and a one-cut finish.

johnbean.com

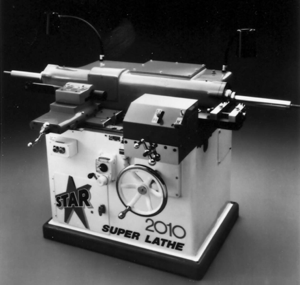

Star Machine and Tool Co.

The Star model 2010 Super Lathe is a unique concept in brake lathe versatility, according to the company, which added the disc and drum lathe is engineered to provide the greatest precision, rigidity and service  life. The model 2010 offers a one-piece, 2,000-pound cast iron housing that has been bored, milled and machined to house the motor, gear case, controls and spindle drives, which are shared by two different lathe operations. According to the maker, it has the power to turn the heaviest dual wheel drum assembly. The 3 hp motor and the positive gear driven carriage will provide a finish cut on the first pass, while the extended spindle nose reduces the cantilevered loads created by heavy dual wheel assemblies and eliminates the need for any outboard support.

life. The model 2010 offers a one-piece, 2,000-pound cast iron housing that has been bored, milled and machined to house the motor, gear case, controls and spindle drives, which are shared by two different lathe operations. According to the maker, it has the power to turn the heaviest dual wheel drum assembly. The 3 hp motor and the positive gear driven carriage will provide a finish cut on the first pass, while the extended spindle nose reduces the cantilevered loads created by heavy dual wheel assemblies and eliminates the need for any outboard support.

starmachinetool.com