According to the National Highway Transportation Safety Administration (NHTSA), tire failures are to blame for approximately 11,000 vehicle crashes per year. That’s why it’s necessary for automotive and tire companies to remove dangerous, defective tires from circulation. In order to do so, they must have the ability to inspect tires quickly and accurately.

Tire dealers must create a speedy and frictionless experience for customers when it comes to what can sometimes be seen as a chore: getting your car into the shop to be inspected. By embracing mobile scanning technology, technicians and service advisers by being able to quickly and accurately scan any tire to ensure that customers drive away with tires that are guaranteed to be safe.

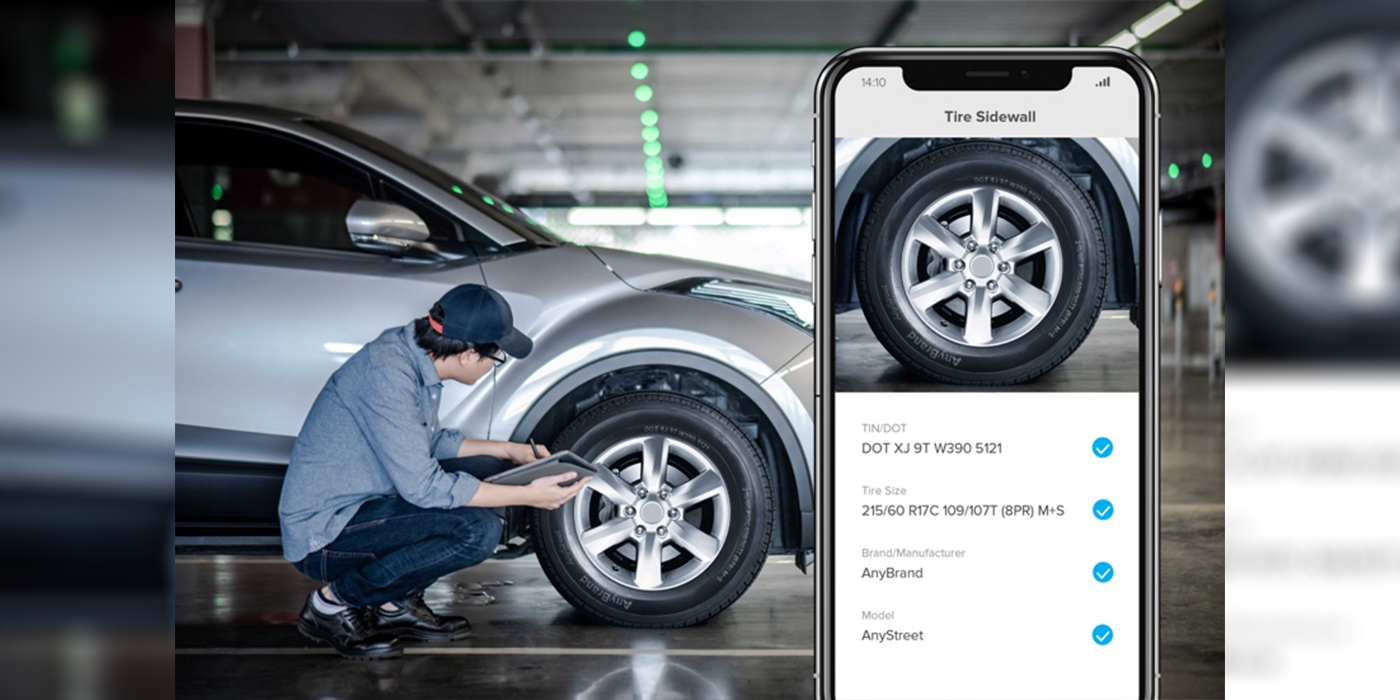

How Mobile Tire Scanning Works

Manually entering DOT numbers from a tire is tedious and time-consuming work, as well as a high-risk area for human error that leads to misidentification and poor-quality data. This arduous process can lead to a less-than-ideal user experience that can decrease customer satisfaction. It’s not uncommon for technicians to use multiple devices to collect data from vehicle parts and tires, adding unnecessary complexity and cost to the process.

By removing manual data entry from the process, mobile tire scanning radically simplifies tire inspection and improves the quality of tire information collected for registering tires. When connected to the NHTSA database, it can alert them to tires that have been recalled due to defects in the manufacturing process.

Most mobile data capture devices are easy to use: just point the scanning device at the tire and let the device’s video camera do the work. Once the mobile scanning software knows what it’s looking at, it transforms the data into a digital output.

Furthermore, mobile data capture works on any camera-enabled smart device, including iOS, Android or UWP devices, as an all-in-one solution for collecting multiple vehicle data points, like the license plate, vehicle identification number (VIN) and even the driver’s license. These solutions can be up to 20 times faster than typing, work even when offline and easily integrate into existing automotive shop management systems and apps, including those built on frameworks like Xamarin, Cordova and React Native.

Benefits for Customers and Tire Dealers

By implementing mobile tire scanning, tire dealers can better ensure their staff captures tire identification numbers and complies with tire registration laws. More importantly, they can ensure customers are driving on tires fit for the road. This is especially important at a time when consumers expect greater transparency regarding how their products are produced. DOT number scanning offers an opportunity for drivers to understand the full lifecycle of their tires, from production and usage to disposal or recycling.

Mobile tire scanning also increases store revenue and workforce performance by digitizing vehicle and tire data. Businesses can empower their tire technicians in retail and fleet service environments to service more vehicles, improve inventory management and provide a better customer experience through greater vehicle uptime operational visibility.

At the end of the day, speeding up the tire inspection process through automation can result in businesses standing out among competitors.

Real-World Implementation

At Discount Tire, store technicians record the DOT number and then perform a tread depth test to see if tires need replacing. Previously, technicians used a pen and paper to record each DOT code manually and measured 12 different spots on the tire to understand tread depth.

In embracing a new mobile handheld solution to automate the process, Discount Tire technicians have been able to complete an assessment typically in under five seconds per tire. Technicians simply swipe each tire to check the tread depth and scan the DOT code with the tool’s camera in real-time, allowing them to assist more customers, reduce wait times and provide a more positive customer experience.

Tire identification numbers take time to record. While we believe most shops record and register tires, most technicians still use pen and paper to do this. And, complete car inspections can last anywhere from twenty minutes to two hours with manual data entry making the process even longer.

AAA suggests that tire tread, tread depth and tire pressure should be self-examined monthly for signs of irregular wear. Chances are, your customers aren’t doing that. However, that’s where their trusted tire dealer comes in. You can be the customer’s guide to making sure their vehicle maintenance is up to date and that they’re rotating their tires every 5,000 to 8,000 miles to spread wear evenly and drive on safe tires.

By integrating mobile data capture into the tire inspection process, tire dealers can automate vehicle, part and tire data collection using their existing hardware and streamline processes in the bay.