Unless you are mounting all new tires at the same time onto a piece of equipment, you need to understand the importance of proper tire matching. Next to air pressure, matching of tires in all positions is critical to the performance of the tires and the piece of equipment.

Today’s on board computers make it more critical than ever to ensure that the overall diameter tolerances on heavy equipment are within the manufacturer’s specifications. Back when the equipment did not feature the new technology, the specification for tires mounted on the same axle (side to side) and front to rear were not as close as they are today. How often do you measure the overall diameter of the tires prior to mounting them on the equipment?

In this article I hope to get you thinking about the importance of tire matching. I will also offer some suggestions to minimize mismatched tires. Careful attention to tire matching and air pressure will ensure maximum serviceability for tire and equipment productivity.

There has always been a lot of discussion about the importance of matching the duals on rigid haul trucks. The tires must be matched for overall diameter/circumference. But how often do you think about the OD difference for articulated dump trucks, graders and loaders? If you do not know what the tolerances should be for a piece of equipment, be sure to contact the equipment manufacturer for its particular specifications. As for the tires, all manufacturers have about the same information for the maximum overall diameter of the tires for the different sizes.

Of course, it is assumed that all tires are inflated to the correct air pressure for their application. A difference in air pressure will affect the weight distribution and load on the tire(s).

Many people ask, “Why is it so important to match tires on the same axle and duals?” There are many reasons, but here are just a few from my point to view:

1. Premature tire removal due to:

a. Heat separations on the larger tire from carrying more load;

b. Irregular tread wear (heal to toe) or rapid centerline wear on the smaller tire as it is rotating faster; or

c. Increased potential of impact breaks and cuts on the tire carrying the load.

2. Drivetrain wear:

a. Differentials

b. Transmission

As the mismatched tires go through their life cycle, the tread wear accelerates much faster on the smaller tires carrying the lighter load. The difference in the overall diameter/circumference between the two duals increases at a more rapid rate.

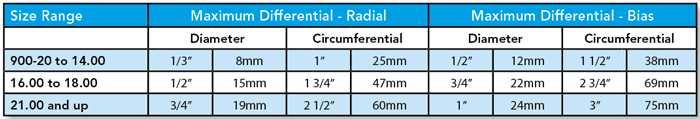

So what is the dual matching for the tires? Table 1 lists the maximum allowance in both the outer diameter and circumferential difference from a couple of different manufacturers. If you have any question regarding the tires you purchase, I would suggest that you contact that specific tire manufacturer. Exceeding the figures listed may result in premature tire removal, which drives up the customer’s cost per hour.

Here are some suggestions to obtain the OD differences:

1. Use a steel tape to measure the circumference of each tire. Then mark the tire so that when it is ready to be installed you can match from the spare pile and install the tire with the same circumference as what is installed on the truck already.

2. Use a right-angled square across the duals. This will help to determine the outer diameter of the tires to make sure they are within tolerance.

3. By using a straight edge or cord across both the right and left duals, the difference can be obtained.

Listed below are some situations that can lead to

the tires being mismatched:

1. Mixing new and worn tires next to each other.

2. Installing an E3 regular depth tire next to an E4 deep tread tire.

3. Different tread designs.

4. Mixing different brands and/or constructions, such as a bias next to a radial.

5. Mounting different section widths. This is not recommended, even if they meet the minimum values for dual spacing. Each tire will deflect differently, which changes the load being carried by each tire.

Any of the above situations can result in tires being mismatched and not working together. Taking the time when mounting the tires will, in the long run, save you time and the customer money.

Here are a couple of points that help to explain what happens when duals are mismatched:

1. A 10% difference in air pressure between duals means an 11% difference in load carried by each tire.

2. Difference of 1/2-inch (~10mm) of tread depth will increase the load by 2% to the larger tire.

3. A worn-out tire installed next to a new tire can increase the load by 55% to the larger tire.

The next topic that needs to be explained and followed closely depending on the equipment manufacturer is the percent difference in the OD of the tire from side-to-side and front-to-rear tolerances. Over the years, the standard used for Caterpillar equipment was 3% side to side and 6% front to rear for their loaders. These percentages have been used for all equipment as an industry benchmark.

Now, with the equipment being much more sophisticated, the tolerances have been changed to better match the equipment. The percentages listed below came from Caterpillar. I would suggest that you check with the each equipment manufacturer to find out what their tolerances are and follow those specifications.

Caterpillar’s recommendations for its equipment:

Loaders:

• The tires size difference from side to side on the same axle should not exceed 3%.

• The difference between the largest tire on the machine and the smallest tire on the opposite axle should not exceed 4%.

Recommended difference for tandems, i.e.

motor graders and articulated dumps:

• No more than a 2% difference in diameter from the front tire and the rear tire on the same tandem.

• No more than a 3% difference in diameter from the largest tire on either tandem to the smallest tire on either tandem.

Following these set tolerances will help to protect you and your company from installing the incorrect tire on a piece of equipment, which could lead to differential or transmissions issues. Again, if there are any questions regarding the tolerances for a piece of heavy equipment, contact the equipment manufacturer. Do not assume all tolerances are the same.

Also, be sure to take the time need to check the diameter difference of the tires when installing them on any wheel position. Especially when you are rotating the tires from not just the fronts to the rears, but also when switching them around on the tandem axles.