Sometimes the best-sounding ideas don’t work well in the real world. For tires, this is especially true when designers have elaborate computer models to support their fledgling ideas.

One of the ideas that sells well, but doesn’t work so well when driven at racetrack pace, is the “multiple-compound-across-the-tread,” or MCATT, tire. (If you have a better generic term, let me know.) The original versions of these tires (they are a bit better these days) had a summer compound on the shoulder, while inboard were abutting tread strips intended to provide good grip on wet roads and at least some mobility in the snow.

They were to be all-things-to-all-people, all-performance, all-season tires. They would offer great grip on dry and damp roads, excellent wet-road performance and some mobility in the snow. Plus, they could open cans, saw branches and pull the cork on a wine bottle.

An aside: Very few “UHP all-season tires” offer more than minimal grip on snowy roads. The best will allow you to limp home if you’re surprised by an early or late-season snowfall. Others are little better than three-season summer tires, even though they embolden you to drive when you should stay put until the roads are clear. Tiremakers self-certify their tires to be “all-season.” Some apparently believe global warming will soon make snow performance moot. Or they’ve accepted the fact that consumers think “all-season” means “good when it rains.”

Almost all of you know this, but it’s worth repeating: “All-season” means the tire gives up dry and damp-road grip to get some mobility in the snow. Sometimes all-season tires give up a whole lot to gain some traction on snowy roads. Sometimes – especially with UHP all-season tires – there is barely a trade-off at all, and the barest of snow traction is the result. Performance in deep water – a tire’s ability to resist hydroplaning – is the job of the tread pattern and (for worn tires) tread depth.

Models vs. Reality

But back to our MCATT tire example. Tire designers are in love with their computer models. Some seem to believe those computer models were carried down Mount Sinai. Sorry, that’s incorrect: They trust the computer models MORE than if Moses himself had touted the programs.

Some designers may, in fact, be convinced reality is incorrect if it doesn’t match the model. But all of this unabashed love can eventually diverge from reality.

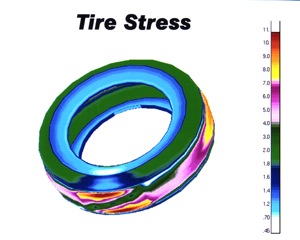

Don’t get me wrong. Computer models are excellent tools for initial tire design. They keep designers from wandering around in unproductive idea cul-de-sacs, saving tire companies millions in building dead-end prototypes. But they are a long way from replacing the testing of actual tires on actual cars driven by actual human beings on actual pavement.

Testing Theories

The theory on MCATT tires was that they would offer grip matching a summer tire when driven to the limit on dry and damp roads. The theory held that cornering force would cause the tire to roll over onto the summer compound on the shoulder. In less aggressive driving on wet and snowy roads, the inner compound would provide adequate traction for those conditions. On damp roads, the summer compound on the shoulder would help grip.

The computer model would look like a hero – if the tire were mounted on a unicycle on a left-turning oval. But a problem appeared on cars driven by non-professionals near – or past – the limit of adhesion on dry and, especially, damp roads.

Almost all automakers design vehicles to understeer (or, if you’re an oval track fan, push) as the vehicle approaches the limit. Understeer (push) means the front tires (specifically, the outside front tire) lose grip before the rears. When a car pushes, drivers’ natural reactions are very close to the ideal solution. They say, “Oh, fudge” (or something similar) and lift off the accelerator. If they react in time, the car stays on the road.

If the rear tires lose traction first, almost all non-professional drivers spin out. This is called oversteer or, for oval racers, being loose. I’ve ridden with about 10,000 people as they attempted – and almost universally failed – to catch a sliding tail of a car that was set up to lose rear grip first. The exceptions were almost all active dirt track drivers. (I asked, “So, what do you race?” when the driver caught the sliding tail. Common answer: “I run 360 Sprint cars every Friday night.”)

With the three-tread tire, as the driver approaches the limit, the outside summer-tire compound becomes loaded. (In a hard corner, the outside tires do almost all the work. Sometimes at the limit a rear tire is literally not touching the pavement.)

For example: As the driver hauls onto a freeway entrance ramp, the rear tire loads its outside edge, but not as much as the front tire. If the car were perfectly balanced (or driven by a professional on a racetrack) this isn’t a bad place to be. The pro may partially release the throttle to get the car to turn into the corner, before accelerating – hard. The outside rear tire is rolled over onto full summer tire compound. If the inside rear doesn’t spin, the car blasts out of the corner. The test driver’s performance thus matches the computer model and everybody’s happy.

The problem happens when there’s a non-professional behind the wheel. A regular person, if you will. Remember “Oh, fudge” and the lift off the accelerator? A normal person doesn’t reapply the throttle when both fronts and rears are sliding. A normal person slows down and waits for his heart rate to return to normal and expects all will return to normal. That wait is the problem.

The moment the driver lifts off the accelerator, the car begins to slow down. If it’s pushing, the scrubbing tires make the car slow rapidly. When the car slows sufficiently, the rear tire begins to return to its static, upright position. The rear’s summer-tire compound is no longer loaded, which means the rear tire isn’t offering its super-special grip.

Meanwhile, the heavily loaded front tire is still rolled over onto the summer compound. There may be just a fraction of a second when the front is on its grippiest part and the rear is off its summer compound. The pro uses it to turn the car. The amateur, meanwhile, is just beginning to analyze the near disaster.

Here’s a quiz: If, in the middle of a corner, the front tires have a lot of grip and the rear tires have much less, what happens? You win if you said, “The car darts whichever way the fronts are pointed.” In this case, the car will snap from severe, but manageable, understeer (push) to only-a-pro-can-catch-it oversteer (really loose).

In this case, neither the carbon-based test instrument or the regular-person consumer match what the golden idol computer model dictated.

Selling performance tires is all about managing expectations, and about knowing the customers’ vehicles and anticipating their true road abilities. Over-selling a tire – rather, selling a tire as cure rather than a tool – is not in your customers’ best interests. No tire will turn a regular-person driver into a professional test driver.

Computer models are good, but they’re not perfect. Nor are test drivers. They are both created by humans.

The lesson here is that tools are great, but drivers are far from perfect. None drive exactly like a computer model. Only reality is infallible, and that is what we are designing and selling products to meet.